About Rotalink Ltd.

Providing infinite possibilities with powerful miniature motor transmission systems

We are a market driven supplier of miniature gearmotor systems and controls. We are dedicated to supporting a global network of 21st century customers who demand world class performance, with added customisability to fit the needs of any project.

Our Business

We power the everyday, every day. But it's your ideas that help make it extraordinary.

Our design philosophy is based upon providing performance with reliability. This we achieve by keeping in touch with the latest innovations but also using proven methods in often novel ways.

Established

We are now in our fourth decade of providing reliable and accurate high quality motion products.

Sq Ft Facility

Rotalink continues to invest in facilities and the latest equipment. Now operating from 4 facilities to support manufacturing demands.

Employees

We have a capable and developing team across all functions to support our customers with a focus on performance and quality.

If you have a project that needs power, we're the power within.

Our customers are friends and our market focused designs enable us to offer them a truly competitive edge. We are lean, with a flat organisation that empowers its people and encourages them to take ownership at a high level. We aim to be positive, professional and have impeccable integrity. Our flexible approach involves understanding your needs and responding in a way that delivers the service you need.

We'll bring your ideas to life.

Specialist sales engineers, supported by our strong design team, are here to help. Samples and prototypes are readily available from our dedicated manufacturing facility.

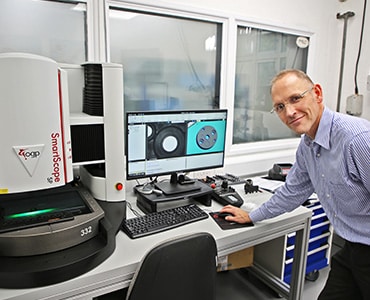

Enhanced value and faster production times with the latest technology

At Rotalink we understand the importance of staying ahead in a highly competitive industry, and as part of our commitment to innovation, we consistently invest in new technology, machinery, and software. By doing so, we enhance our manufacturing capabilities, improve efficiency, and maintain a high level of quality in all of our products.

Producing quality, eeliable products remains at the heart of our team

Rotalink is known for a commitment to quality. We employ rigorous inspection and testing processes throughout our manufacturing process, ensuring high standards are met. Skilled technicians assemble products with precision, and our comprehensive testing evaluates performance parameters.

Rotalink maintains a strong quality management system, prioritising customer satisfaction and continuous improvement for reliable drive systems.

Crafting bespoke drive systems through careful design

Rotalink employs a careful design process to create bespoke solutions for customers' unique requirements. They collaborate closely, utilize advanced design tools, and incorporate customer feedback to deliver tailored drive systems that provide optimal performance.

Technical expertise and extensive experience in bespoke drive systems

Rotalink has technical expertise and extensive experience in the miniature motor and gearbox industry. They develop innovative solutions and successfully tackle diverse challenges, ensuring smooth collaboration and delivering bespoke drive systems with precision.

Project Management

Successful product deliveries with a strong partner; Rotalink

At Rotalink, established in 1986, we bring decades of experience to meet the individual requirements of complex applications. Our experienced engineers and technicians support customers from the specification phase through to production and beyond, ensuring constant transparency, flexibility, and proactive communication.

Our interdisciplinary team of experts is ready to support you with your specific application needs.

Our History

The History of Rotalink Ltd.

Rotalink established from acquisition of Sterling Instruments

Acquired Londex range of Controls from Cambridge Instruments

Major Project with London Underground to upgrade rolling stock.

Expansion into second unit with clean zone

Acquired Elremco range of motors and pneumatic cam timers

Acquired Stemshire range of die cast gearboxes

Major Development of Gearbox ranges started

Expansion into 3rd Unit for OEM Projects

PG Planetary gearbox range launched

Pressed body brushless motors launched

Expansion into 4th Unit, alongside a Major Factory reorganisation

Our Vision

To be globally recognised centre of excellence in a world reliant on motorised technology.

Our Mission

To create exceptional, innovative and customer-centric miniature motor transmission systems, delivered by a team of experts.

Our Values

Lead with kindness. Always keep learning. Drive your ambition.

Modularity; Bringing your ideas to life.

Our design philosophy has modularity at its core. Our aim is to meet the specification set by the widest range of applications with a unique power transmission package built from standard components.

The resulting catalogue enables us to deliver three key demands arising in a highly competitive global marketplace: performance, cost and time.

Our motors are sourced from both internal and external suppliers. We work hard to ensure that our products meet specification and quality expectations with premier service and customer support.

Our Engineering team and Modern manufacturing facilities ensure high quality supply of Motor and gearbox products.

If standard products are not suitable our applications and Design engineering team can work to meet special requirements.

The sales team will be pleased to help with the selection of the most effective product. Please contact us.

Miniature Motor Parts Manufacturing

Motor and Gearbox Analysis

Miniature Motor Testing and Quality Control

What makes us different?

Why Choose Rotalink?

High Torque

Rotalink systems vs. direct motor drive

Rotalink Motor gearboxes offer high torque output compared to their weight.

1/10th of the weight of an equivalent torque stepping motor.

Ratio Choice

Ratios to suit every requirement

Rotalink systems offer gear reduction ratios from 2:1 up to a mighty 720,000:1.

Need to rotate 3 times a second or once a month we have it covered.

Customisation

Highly configurable and customisable

Rotalink can offer the ideal design to integrate perfectly into your equipment.

- Special shaft

- Custom drive pinions

- Wiring and connector options

Quiet Operation

Low disturbance

For ultraquiet demands semi rigid polymers can be implemented to damp geartrain noise.

Gear designs can optimise meshing contact to reduce transmission noise.

Rotalink geartrains use an optimised mix of polymer and metal components.

Affordability

Highly optimised designs

For the performance benefits Rotalink systems offer affordable high torque motion.

Rotalink products are designed for performance and Rotalink has invested in efficient precision volume manufacturing capability

Form Factors

Rotalink flexibility

Rotalink Ovoid gearbox systems enable high torque installation where axial distance is restricted.

Planetary gearboxes are ideal where diametral space is restricted and axial drive is ideal.

Compact integrated designs can be achieved.

Zero Power to Hold

Lower overall energy use - Hold position when stationary

Rotalink systems can be configured to be non backdrivable when power is off.

Careful selection of gear design and ratio.

Use of motor detent torque resistance amplified via gear train to hold.

For applications with periods at rest overall energy can be greatly reduced.

Lightweight

It ain’t heavy…

Rotalink Gear systems used thin wall pressed cases for light weight.

Gear trains are lightweight, stiff, wear resistant engineering polymers.

Polymer bearings in the lightest transmission solutions.

Reliability

Torque you can count on

Careful matching of gear system design to application requirements

Highly optimise motor products

Decades of experience in precision manufacturing of geartrain components