Diving into the detail

Knowledge Base and Insights

Choose from our wide range of miniature motor transmission systems to find the perfect match for your product. Our motors can be found to be powering everyday objects, every day. From powering your morning caffine fixes to life saving equipment.

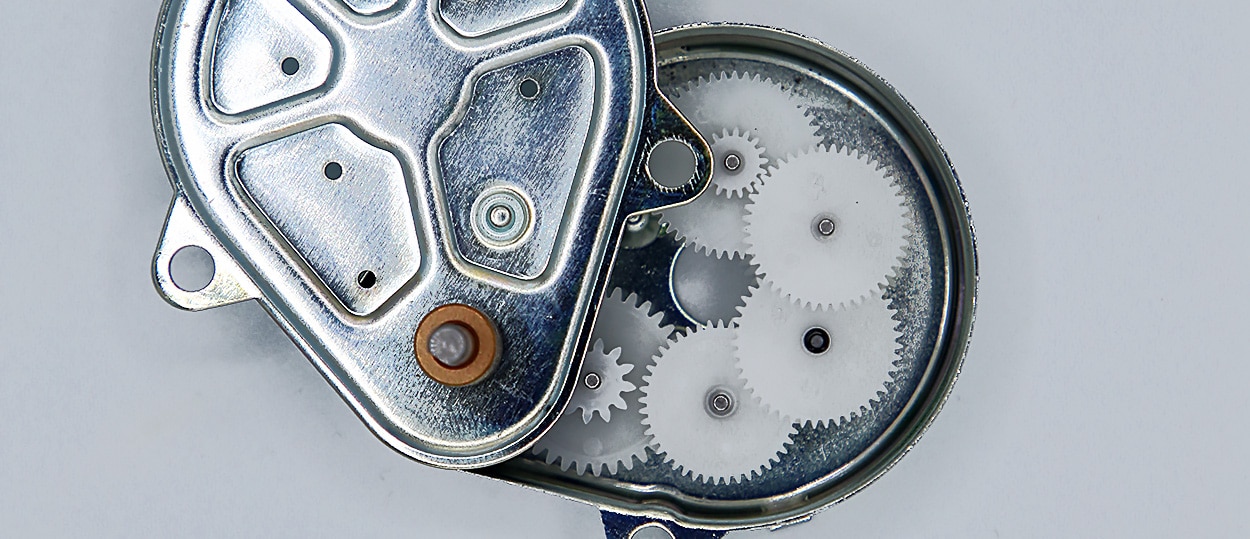

Understanding Gear Ratios and Their Impact on Motor Performance

Gear ratios play a crucial role in motor performance, influencing speed, torque, and efficiency. Learn how to optimise your system with the right gearing solutions.

Categories

Please select a category to view the topics you're looking for.

Send us an enquiry

Take the first step towards unmatched efficiency and precision.

Contact Rotalink today and discover how our gearmotors can transform your machinery into a powerhouse of performance.

Knowledge Based Articles

Our Recent Posts and Knowledge Base Insights

Miniature Gearmotors for Car Mirror Positioning

Discover how Rotalink’s miniature gearmotors provide precise, quiet, and reliable movement for car mirror adjustment systems.

Synchronous Motors: Principles and Uses

Synchronous motors provide precise speed control and efficiency, making them ideal for automation, medical devices, and smart electronics. Find out how they work and where they're used.

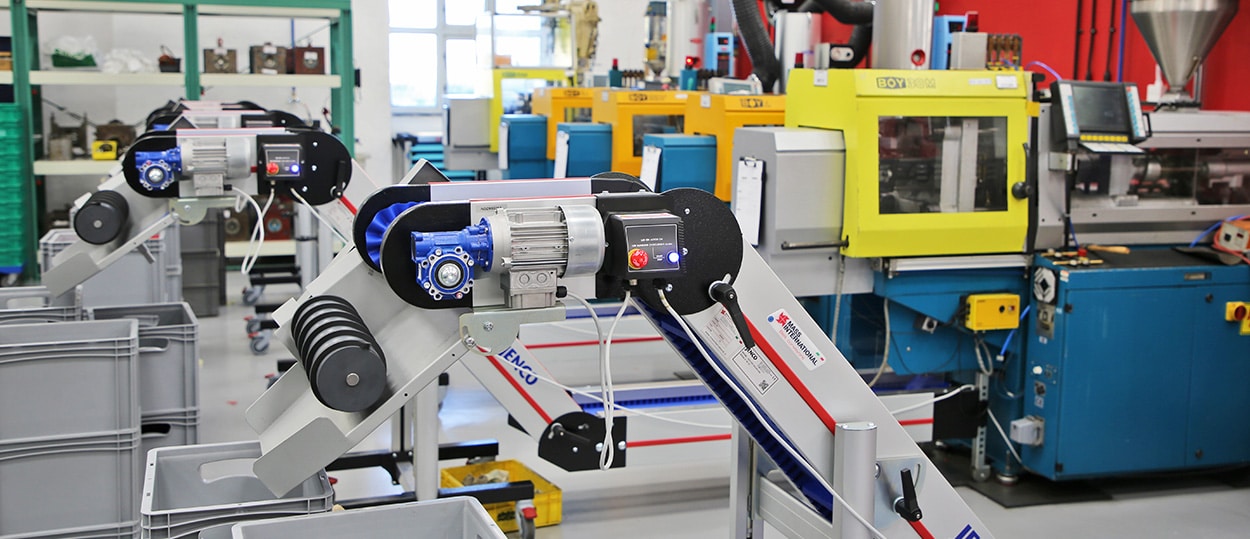

Optimising Small-Scale Automation with Miniature Gearmotors

Explore how miniature gearmotors revolutionise compact devices and automated systems, focusing on their versatility, efficiency, and precision.

Meeting the Challenges of Precision Engineering in Small Spaces

Rotalink's customised miniature gearmotors meet the toughest precision engineering challenges in small spaces. Explore our solutions tailored for compact designs.

Improving Efficiency in Vending Machines with Gearmotors

Explore how Rotalink’s miniature gearmotors enhance vending machines' performance. Learn about custom solutions for snack, drink, and coffee vending applications.

Rack and Pinion Gears – Advantages in Miniature Systems

Explore the precision, durability, and versatility of rack and pinion gears. Learn how Rotalink customises miniature gearmotor systems for linear motion applications.

Helical Gears – Applications and Advantages

Discover the unique design and benefits of helical gears. Learn how they excel in high-performance applications and explore alternative gear solutions offered by Rotalink.

Gearmotors for Water Filtration Systems

Miniature gearmotors play a crucial role in water filtration systems, providing reliable and efficient operation for pumps, valves, and automation processes.

Explore our Application Stories

Real World Examples of Our Gearmotors

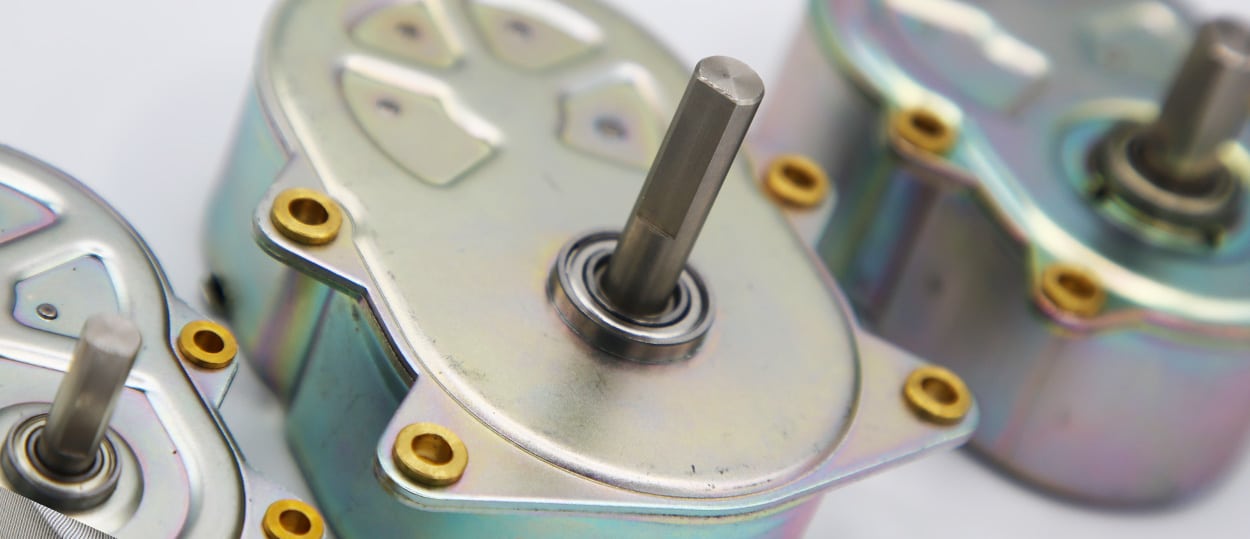

Custom Motors for Turntables

We've partnered with a large manufacturer of turntables, renowned for their commitment to quality audio experiences.

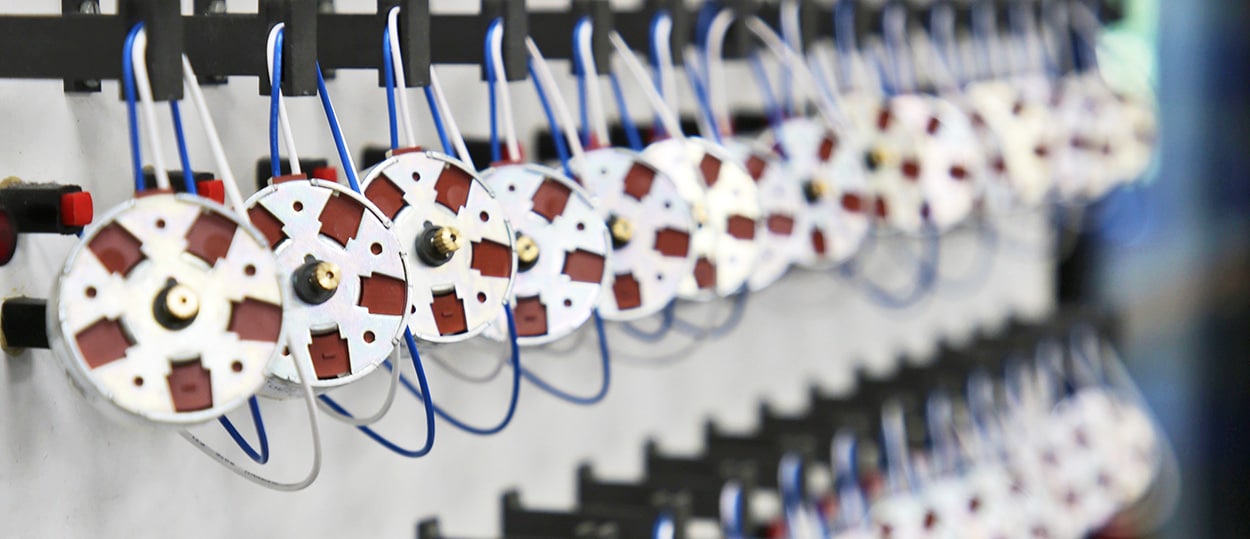

Coffee Machine DC Gear Motor

Rotalink has been providing DC Geared Motors for coffee machines for a number of years now. Providing efficiency in both manufacturing times and motor output.

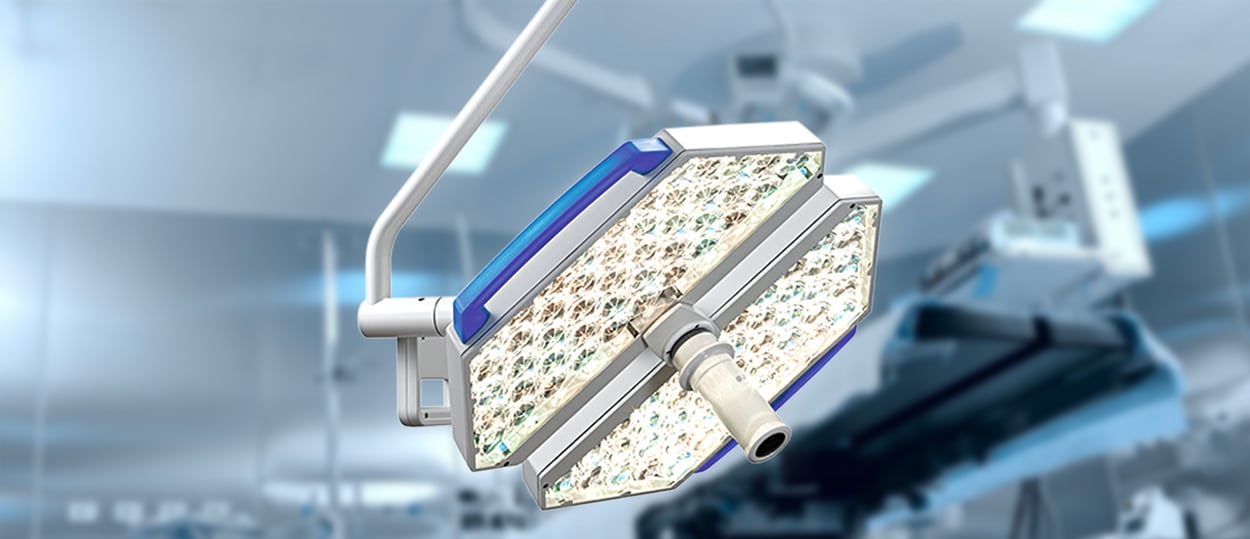

Miniature Motor for Surgical Lighting

Discover how our technical engineers were able to design a bespoke stepping motor. mounting bracket and pinion for operating room equipment.

Gearmotor for a Shower Unit

Discover the future of shower control with geared motors! Explore how miniature geared motors revolutionise remote-controlled showers.

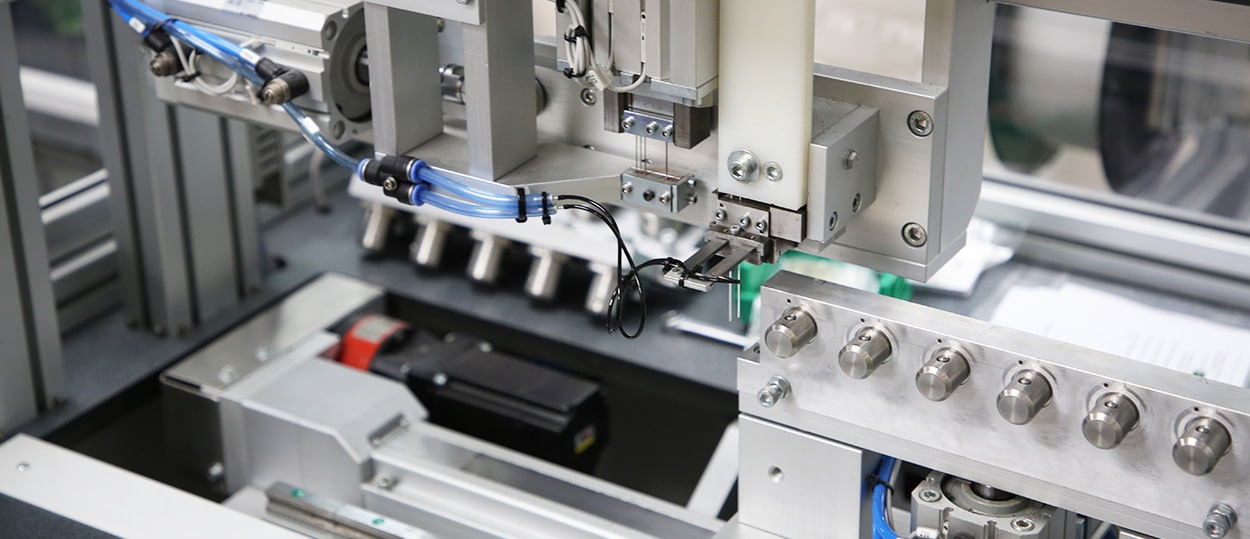

Gearmotors for Letter and Envelope Organising

Rotalink gearmotors are utilised in the actuators that execute the mail folding and envelope-inserting process.

Gearmotors for Eye Test Equipment

Rotalink Stepper Motors have been used in flagship eye testing equipment across the world! Find out more about the way our gearmotors have been utilised.

Gearmotors for Peristaltic Pumps

Often used in dosing systems, our gearmotors can be found in peristaltic pumps all over the world. Peristaltic pumps are perfect for controlling the flow of chemicals and abrastive fluids.

DC Gearmotors for ATM Machines

Rotalink products are used in every stage of this process, from note retrieval to presentation, to ensure the safe and efficient operation of cash-dispensing machines.

Understanding Industry Terms

Our Glossary of Industry Terms and Phrases

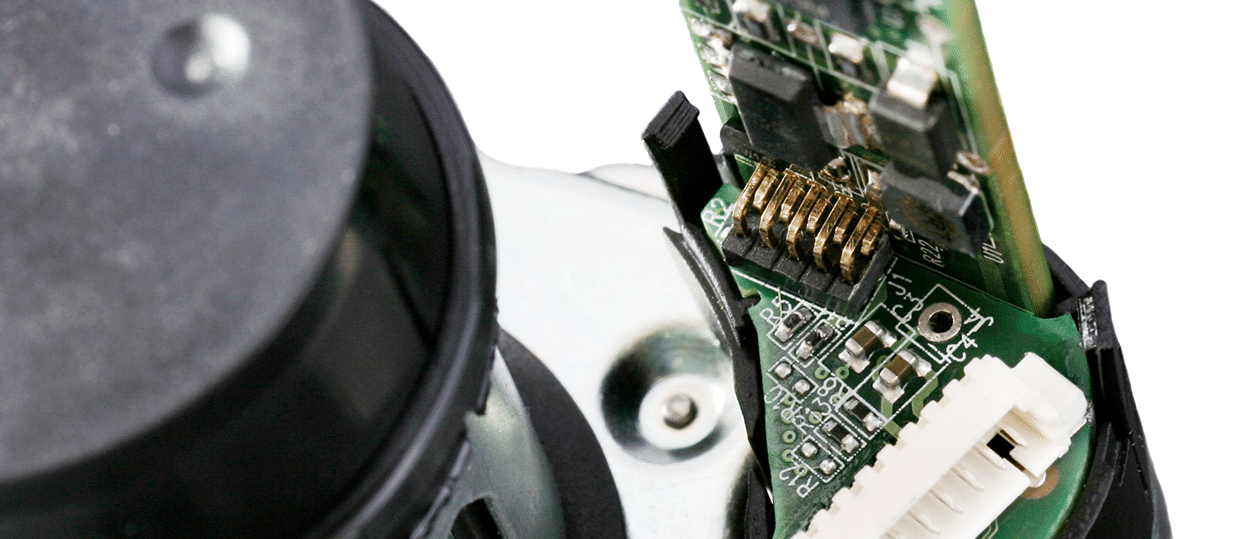

Magnetic Encoders

Explore how magnetic encoders enhance precision in miniature gearmotors, offering durability and cost-effective motion control for a variety of applications.

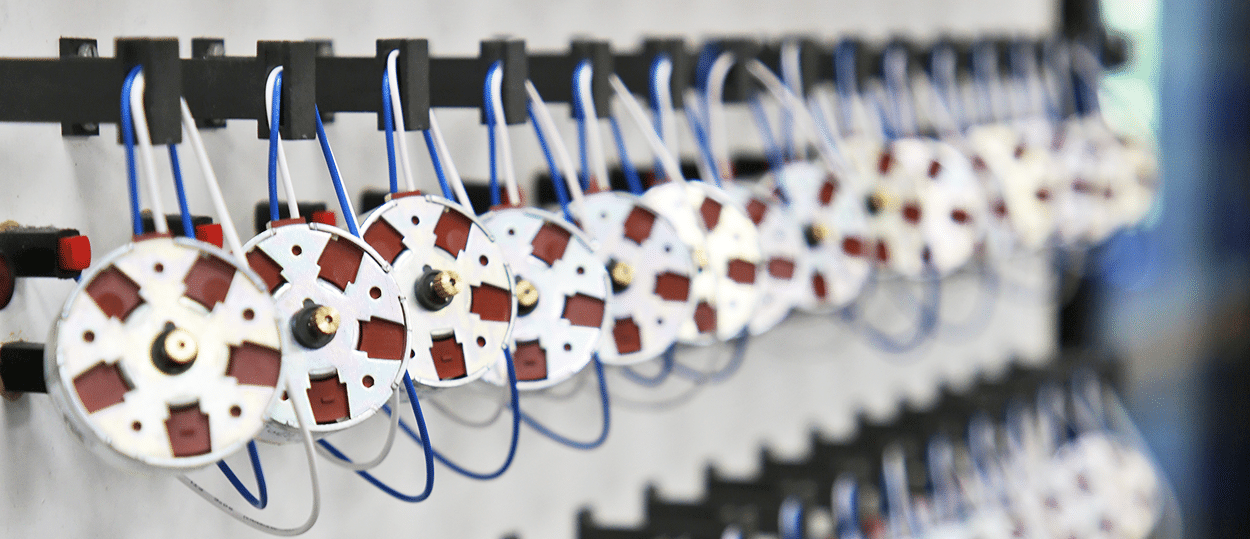

Miniature Synchronous Motor: Principles and Uses

Discover the principles and advantages of synchronous motors for precise speed control in a wide range of different applications.

Understanding the Characteristic Curve Slope in Motors

The characteristic curve slope of a motor is a key parameter that defines the relationship between its speed and torque.

Worm Gears: Applications & Advantages

Worm gear motors offer a unique combination of high reduction ratios, compact design, and self-locking capabilities, making them an excellent choice for various applications.

Spur Gears: Applications & Advantages

Spur gears are among the most commonly used gears in various mechanical applications. Known for their simplicity and efficiency, these gears play a vital role in numerous industries.

Understanding Zero-Backlash Spur Gearheads

Zero-backlash spur gearheads are precision-engineered components designed to eliminate gear play, ensuring high accuracy and efficiency in mechanical systems.

Servomotors

Discover the diverse types of servomotors, their dynamic control features, and how Rotalink customises servomotors to meet your exact specifications.

Thermal Management in Miniature Gearmotors

At Rotalink, we recognise the critical role that temperature control plays in maximising the efficiency, reliability, and longevity of our gearmotor solutions.