2025 Guide: How to Choose the Right PM Stepper Motor for Your Project

In the evolving landscape of automation and robotics, choosing the right PM stepper motor is crucial. According to a recent market report from Research and Markets, the global stepper motor market is expected to reach $5.23 billion by 2026, highlighting the growing demand for precision control. Understanding the characteristics of PM stepper motors can significantly impact project outcomes.

Expert opinions shed light on this topic. Dr. Emily Chen, a renowned specialist in motion control systems, once remarked, "The choice of a PM stepper motor can either make or break your project's success." This emphasizes the importance of thorough evaluation. Selecting motors that align with specific project needs requires careful consideration of torque, size, and efficiency.

Unfortunately, many projects fall short due to a lack of understanding. Engineers often overlook critical specifications. This can lead to inefficiencies or even complete project failures. The journey of choosing the right PM stepper motor is not as straightforward as one might think. It's a path that demands attention to detail and a willingness to learn from past mistakes.

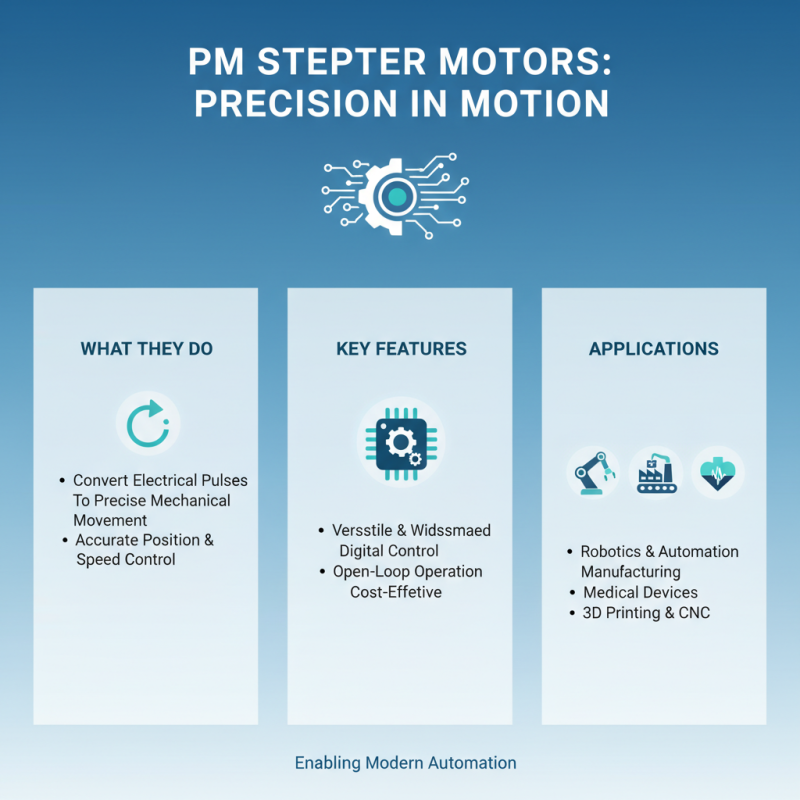

Understanding PM Stepper Motors and Their Applications

PM stepper motors are versatile and widely used in various applications. They convert electrical pulses into precise mechanical movement. These motors play a crucial role in robotics, manufacturing, and medical devices. Their ability to control position and speed accurately makes them ideal for automation tasks.

When selecting a PM stepper motor, consider your project's specific needs. What is the required torque? How fast does it need to move? These questions guide your choices. Pay attention to factors like voltage, current, and steps per revolution. Each motor has distinct characteristics. Some may not fit your requirements perfectly.

It's also essential to assess power supply compatibility. Improper voltage can lead to inefficiencies. Ponder the overall system design. Will the motor integrate smoothly with other components? Considerations like heat generation and noise levels can influence your project. Balancing these factors is a challenge but crucial for success.

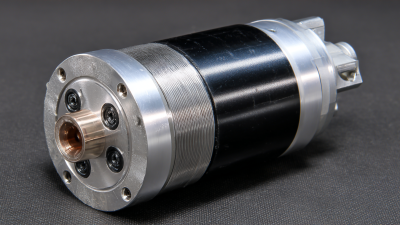

Key Specifications to Consider When Choosing a PM Stepper Motor

Choosing the right PM stepper motor involves several key specifications. Torque, for instance, is crucial. A motor with insufficient torque may not perform as expected. Common benchmarks suggest that a motor should deliver at least 0.5 Nm for basic applications. Applications requiring higher precision may need motors with torque exceeding 1 Nm. It’s essential to assess your project’s requirements to avoid underperformance.

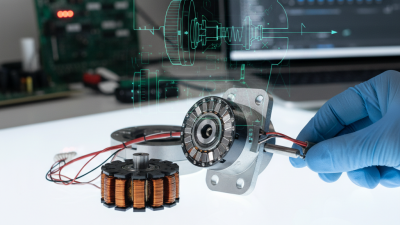

Another critical specification is step angle. Most PM stepper motors have a step angle of 1.8 degrees. For high-resolution applications, smaller step angles of 0.9 degrees are preferable. However, this increases complexity and may require advanced drivers. Many users overlook the importance of driver compatibility, leading to performance mismatches.

Additionally, consider current ratings. Higher current ratings imply more power but also increased heat. This can affect lifespan. A report from the International Electromechanical Association notes that many users underestimate heat management, risking motor failure. Balancing these specifications is a challenging task. Designers often find themselves questioning their choices, seeking the best path forward.

2025 Guide: How to Choose the Right PM Stepper Motor for Your Project - Key Specifications to Consider When Choosing a PM Stepper Motor

| Specification | Description | Typical Value |

|---|---|---|

| Step Angle | The angle in degrees the motor moves per step. | 1.8° (200 steps/revolution) |

| Holding Torque | The torque maintained when the motor is not moving. | 0.5 - 2.0 Nm |

| Rated Voltage | The voltage the motor is rated to operate at. | 12 - 48 V |

| Rated Current | The current the motor is designed to draw under rated conditions. | 1 - 4 A |

| Step Mode | The mode of operation, such as full-step or micro-stepping. | Full-Step / Half-Step / Micro-Step |

| Weight | The weight of the motor. | 0.5 - 2.5 kg |

| Temperature Range | The operational temperature range of the motor. | -20°C to 60°C |

| Shaft Diameter | The diameter of the motor shaft. | 5 - 10 mm |

Evaluating Torque and Speed Requirements for Your Project

When choosing a PM stepper motor for your project, evaluating

torque and

speed requirements is crucial.

Torque is essential for moving loads effectively. A study by the International Society of Automation

indicates that motors with higher torque ratings (over 0.5 Nm) often perform better in

demanding applications. Speed, measured in RPM, also plays a significant role. Ideal motor speed

usually ranges from 300 to 1200 RPM for most applications.

Consider the load characteristics. A heavier load requires more torque. For instance, if you need to lift

a load of 5 kg at a speed of 25 cm/s, a motor with suitable torque is needed.

Using torque curves can help visualize this relationship.

A miscalculation here can lead to underperformance. On the other hand, oversizing the motor may lead to

inefficiencies.

It's vital to balance these factors. A common mistake is focusing too much on one element. Higher torque

often means lower speed capabilities. Finding the right balance is key. Re-evaluating the project requirements

can lead to better performance. Feedback from prototypes can reveal unexpected challenges. Adjusting

specifications based on real data is part of the design process.

Selecting the Right Drive Type for Your PM Stepper Motor

When selecting a PM stepper motor, choosing the right drive type is crucial. Stepper motors can operate with different driving methods, including open-loop and closed-loop systems. An open-loop drive is simpler and often less expensive. It works well for many basic applications. However, it lacks feedback, which might lead to issues in precision.

On the other hand, closed-loop drive systems offer better control and accuracy. They provide real-time feedback, allowing adjustments during operation. If your application requires high precision or has variable loads, a closed-loop setup could be the right choice. Yet, this complexity may introduce challenges. It requires more components and can increase project costs.

It's also essential to consider the step angle of the motor. Smaller step angles mean finer control but can complicate the drive requirements. Evaluating your project’s specific needs is key. What works perfectly for one application may not suit another. Planning ahead and weighing the pros and cons of each system helps in making an informed decision.

Common Pitfalls to Avoid in Choosing PM Stepper Motors

When selecting a Permanent Magnet (PM) stepper motor, many engineers overlook crucial factors. Common pitfalls can lead to performance issues. For instance, not considering torque requirements may result in insufficient drive power. According to industry reports, over 30% of design failures stem from inadequate motor specifications.

Tip: Always calculate the necessary torque for your application. This step ensures you avoid serious performance limitations.

Another mistake is neglecting heat management. PM motors generate heat, impacting efficiency. If your design lacks proper cooling solutions, it could lead to thermal overload. Surveys show that nearly 25% of motor failures occur due to overheating.

Tip: Assess the environment where your motor operates. Ensure there’s adequate airflow or consider thermal management systems.

Lastly, engineers often forget about the control system. A motor's performance relies heavily on the controller's compatibility. If they misalign, stepper motors may skip steps. Report data indicates that misconfigured systems lead to around 20% of all motor-related issues.

Tip: Validate your control system's specifications against the motor’s capabilities for optimal results.

2025 Guide: How to Choose the Right PM Stepper Motor for Your Project

This bar chart displays the common specifications for PM stepper motors, including torque, speed, current, voltage, and weight. Understanding these parameters can help you avoid pitfalls in selecting the right stepper motor for your project.

Related Posts

-

Why Choose Permanent Magnet Stepper Motors for Your Next Project?

-

Top 10 Benefits of Using Permanent Magnet Motors in Modern Applications

-

What is a Permanent Magnet DC Motor and How Does it Work

-

What is Rotor Magnet and How Does it Work in Electric Motors

-

2025 Top 5 Permanent Magnet DC Motor 180V Options for Enhanced Performance

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology