2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

The axial flux permanent magnet motor (AFPMM) is poised to revolutionize various industries with its high efficiency and compact design. According to a report by Research and Markets, the global axial flux motor market is forecasted to grow significantly, reaching an estimated value of $2.5 billion by 2027, driven by increasing demand in the electric vehicle sector and renewable energy applications. As industries seek higher performance and energy efficiency, innovations in AFPMM technology are becoming critical.

Dr. Elena Robinson, a leading expert in motor technology, highlights the potential of axial flux motors, stating, " The unique structure of axial flux permanent magnet motors allows for superior power density, making them ideal for modern transportation and energy systems." Her insights reflect a growing recognition in the industry that these motors can outperform traditional radial designs, especially in applications requiring lightweight and compact solutions.

Dr. Elena Robinson, a leading expert in motor technology, highlights the potential of axial flux motors, stating, " The unique structure of axial flux permanent magnet motors allows for superior power density, making them ideal for modern transportation and energy systems." Her insights reflect a growing recognition in the industry that these motors can outperform traditional radial designs, especially in applications requiring lightweight and compact solutions.

In this analysis, we will explore the top five innovations in axial flux permanent magnet motor technology projected for 2025. By examining advancements in materials, design techniques, and manufacturing processes, we aim to provide a comprehensive overview of how these innovations are set to reshape the future of motor technology.

Advancements in Axial Flux Motor Design and Efficiency Optimization

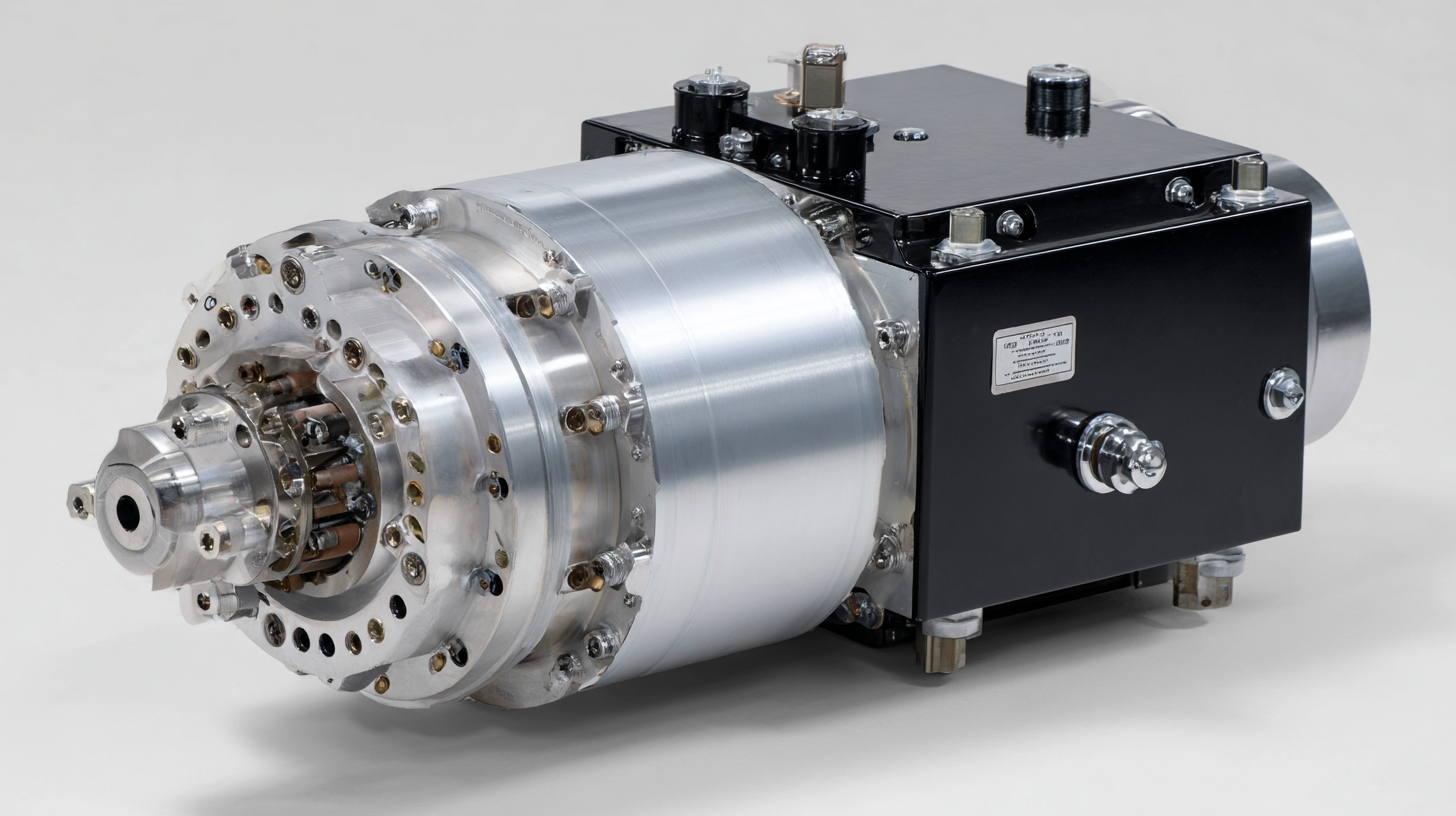

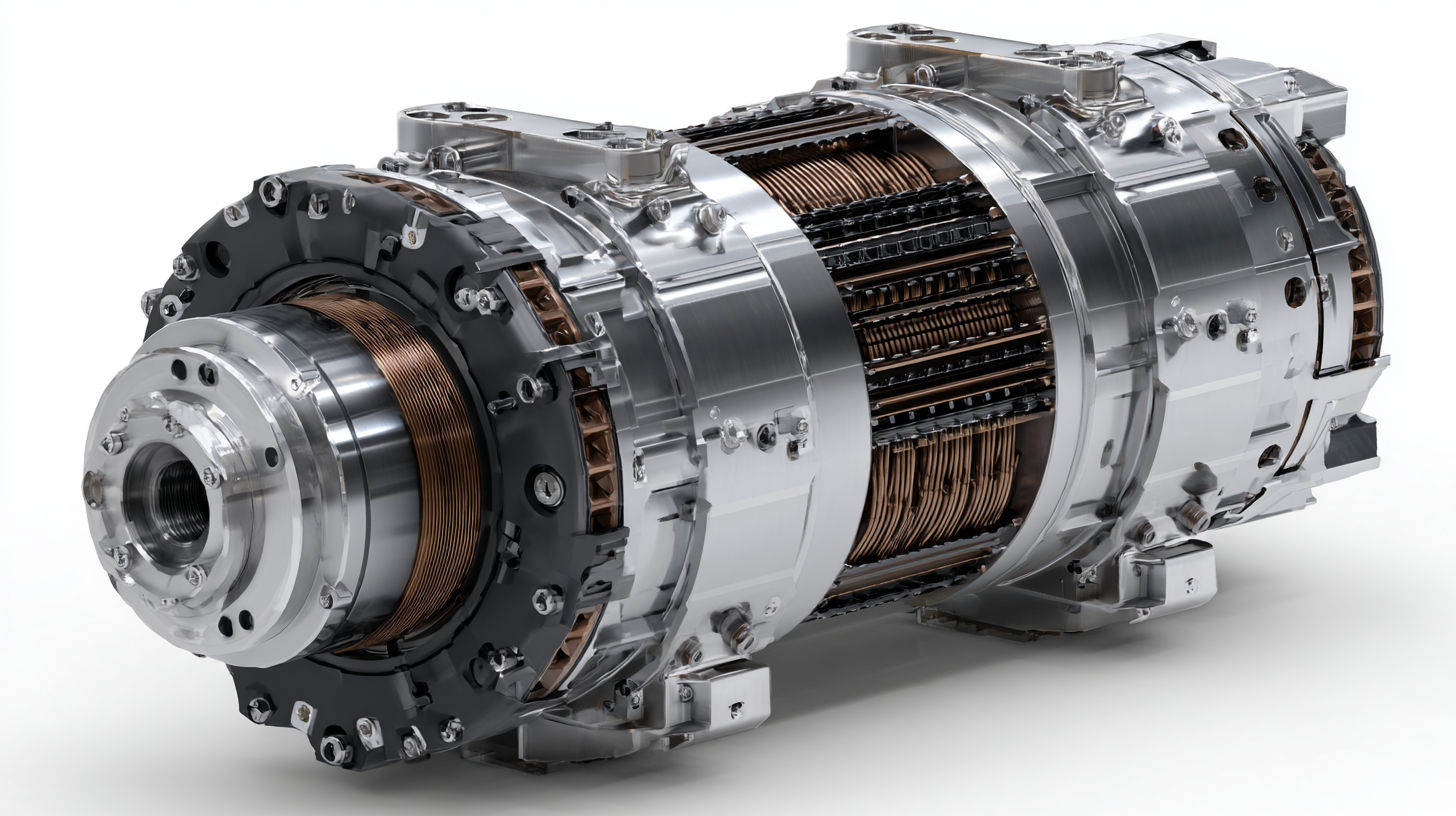

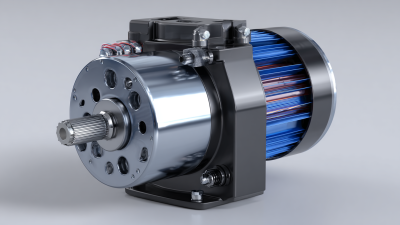

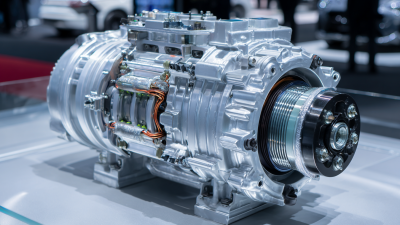

The advancements in axial flux permanent magnet motor design are set to revolutionize the electric motor industry by significantly enhancing efficiency and performance. One of the most remarkable improvements lies in the reduction of the motor’s footprint.

By leveraging a disc-shaped configuration, axial flux motors can achieve higher torque density in a more compact design compared to traditional radial flux motors. This space-saving design not only facilitates integration into various applications but also contributes to weight reduction, which is crucial for electric vehicles and other portable technologies.

Moreover, the efficiency optimization of axial flux motors is being enhanced through advanced materials and innovative cooling techniques. The use of high-performance magnets and lightweight composite materials enables motors to operate at higher temperatures without compromising their structure or efficiency. Additionally, implementing sophisticated thermal management systems allows for better heat dissipation, extending the lifespan of the motor and improving its reliability.

Tips: When considering an axial flux motor for your application, focus on the specific performance metrics crucial for your use case. Evaluate the thermal management solutions provided, as efficient cooling directly affects motor performance and longevity. Always stay updated with the latest advancements in magnet technology, which can significantly enhance motor efficiency and overall effectiveness.

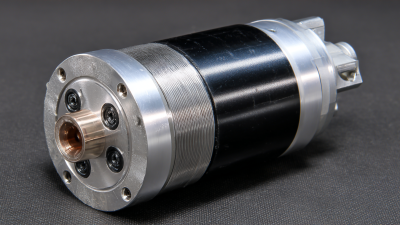

Breakthroughs in Magnet Materials for Enhanced Performance

The advancements in magnet materials have been pivotal in the evolution of axial flux permanent magnet (AFPM) motors. Researchers are focusing on high-performance materials such as rare-earth magnets, which offer superior magnetic properties compared to traditional iron-based magnets. For instance, a recent report from the International Energy Agency highlights that the use of neodymium-iron-boron (NdFeB) has enhanced the efficiency of these motors by up to 30%. This increase not only boosts performance but also significantly reduces energy consumption, making them an appealing choice for electric vehicles and renewable energy applications.

**Tip:** When considering AFPM motors for industrial applications, assess the specific magnet material's grading and temperature resistance, as these factors directly influence the motor's overall efficiency and longevity.

Breakthroughs in magnet technology are also seeing a shift towards sustainable and environmentally friendly materials. Innovations such as polymer-bonded magnets and the recycling of rare-earth materials are emerging as not only cost-effective but also eco-conscious solutions. A recent market analysis projects the demand for such advanced materials to increase by over 40% by 2025, indicating a strong trend towards sustainable manufacturing practices in the motor industry.

**Tip:** Stay updated on the latest trends in magnet materials and consider investing in R&D to ensure your applications harness the full potential of AFPM technologies.

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

The chart below illustrates the advancements in axial flux permanent magnet motor technology, focusing on breakthroughs in magnet materials that enhance performance across various dimensions.

Innovations in Cooling Technologies for Axial Flux Motors

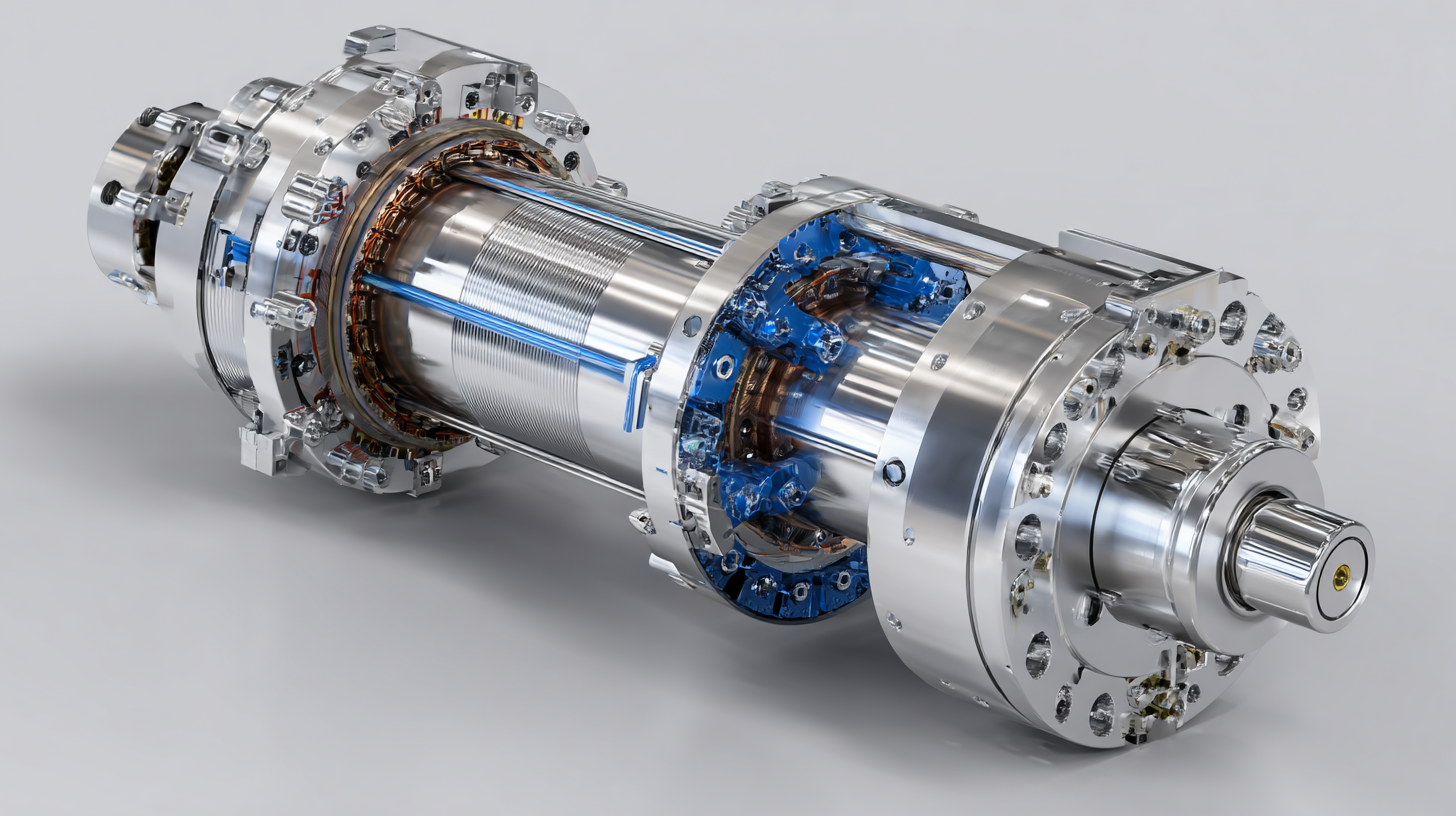

Recent advancements in cooling technologies for axial flux permanent magnet motors have emerged as a pivotal development in the pursuit of enhanced efficiency and performance. Traditional cooling methods often struggle to sufficiently dissipate heat generated during operation, leading to decreased motor performance and longevity. However, innovative approaches such as active liquid cooling systems and enhanced air cooling techniques are beginning to take center stage, offering significant improvements in thermal management.

One promising innovation includes the integration of microchannel cooling, which utilizes small channels within the motor's structure to facilitate the efficient flow of coolant. This method not only maximizes contact with critical heat-generating components but also minimizes weight, a common concern with traditional cooling solutions. Additionally, the adoption of phase change materials (PCMs) is gaining traction, as these materials can absorb excess heat and release it when the temperature drops, providing a passive cooling solution that enhances the thermal stability of the motor.

These advancements in cooling technologies are crucial for maximizing the capabilities of axial flux motors, enabling them to deliver higher power outputs while maintaining operational integrity. By addressing the thermal challenges associated with these motors, manufacturers can push boundaries, leading to more compact designs and improved energy efficiency in various applications, from electric vehicles to industrial machinery.

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology - Innovations in Cooling Technologies for Axial Flux Motors

| Innovation Type | Description | Cooling Efficiency Improvement | Expected Market Impact |

|---|---|---|---|

| Advanced Liquid Cooling Systems | Utilizes a closed-loop liquid cooling design to enhance thermal dissipation. | Increases cooling efficiency by up to 30%. | Predicted to drive a 15% increase in market share for axial flux motors. |

| Superconducting Materials Integration | Incorporates superconductors to minimize losses and dissipate heat effectively. | Achieves near-zero resistance leading to significant heat reduction. | Expected to revolutionize performance metrics and gain substantial market traction. |

| Nano-Enhanced Cooling Fluids | Employs nanotechnology to create advanced cooling fluids that improve thermal conductivity. | Enhances heat transfer rates by up to 40% over conventional fluids. | Anticipated to expand market applications in high-performance motors. |

| Innovative Heat Exchanger Designs | Features compact and efficient heat exchangers tailored for axial flux configurations. | Improves overall cooling system effectiveness by 25%. | Promising growth in heat management segments of the motor industry. |

| Smart Cooling Solutions | Integrates sensors and IoT technology for real-time cooling management. | Dynamic adjustments lead to at least a 20% improvement in cooling response. | Sought to enhance operational reliability in various applications. |

Integration of Smart Sensors and IoT in Electric Motor Systems

The integration of smart sensors and the

Internet of Things (IoT) is revolutionizing electric motor systems,

particularly in the field of axial flux permanent magnet motors. The global

current sensor market is projected to reach $5.27 billion in 2025,

with a compound annual growth rate (CAGR) of approximately 1.9%

through to 2034. This projection highlights the increasing demand for precise monitoring

and control within electric motor systems, further fueled by advancements in sensor

technologies like Hall effect sensors and resistance sensors.

As industries increasingly adopt IoT solutions, the application of both direct

and indirect current sensing methods becomes vital. The utilization of both

open-loop and closed-loop systems allows for enhanced performance

and reliability in various sectors including manufacturing, aerospace,

and energy. Moreover, recent reports indicate that the global

vibration monitoring market is also expanding, driven by

the need for predictive maintenance in industrial equipment, ensuring operational

efficiency through the continuous analysis of mechanical vibrations. Such innovations not only

optimize performance but also contribute to the broader digital transformation efforts

across multiple industries.

Future Trends in Manufacturing Techniques for Cost-effective Production

The manufacturing techniques for axial flux permanent magnet motors are rapidly evolving, driven by the need for cost-effective production methods. Innovations such as additive manufacturing and advanced automation are becoming increasingly essential in optimizing the production process. These methods not only enhance precision and reduce material waste but also accelerate the manufacturing timeline, allowing companies to respond to market demands more efficiently. As manufacturers strive for sustainability, the integration of eco-friendly materials and processes will also play a crucial role in shaping future production techniques.

Furthermore, the anticipated growth in the overall market for axial flux permanent magnet motors highlights the urgency for companies to adopt these innovative manufacturing solutions. The projected increase in market demand underscores the necessity for cost-effective practices that can bolster competitiveness. With rising investment in research and development, the focus will likely shift toward developing smarter manufacturing systems that leverage data analytics and IoT technologies, thus paving the way for a new era in the production of electric motors. The convergence of these advancements promises a significant transformation in the efficiency and sustainability of manufacturing processes.

Related Posts

-

What is a Permanent Magnet DC Motor 90V and How Does it Work

-

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

-

Exploring the Future of Energy with Permanent Magnet Motor Generators

-

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

-

2025 Top 5 Permanent Magnet DC Motor 180V Options for Enhanced Performance

-

Exploring the Efficiency and Applications of Permanent Magnet DC Motors at 90V