2026 Best Electric Motor Magnet Choices for Optimal Performance?

When considering the best electric motor magnet choices for optimal performance, several factors come into play. Electric motor magnets are crucial for efficiency and durability. The right choice can enhance performance while reducing energy consumption. Many options exist, and each has its unique advantages.

Different types of electric motor magnets, such as neodymium, ceramic, and ferrite, each serve specific needs. For instance, neodymium magnets stand out for their strength. However, they can be more costly and may require careful handling. On the other hand, ceramic magnets are more affordable, but they might not provide the same performance level in high-demand applications.

It’s clear that selecting the right electric motor magnet is not a straightforward task. The market is vast, filled with competing technologies and specifications. Users should reflect upon their individual requirements and be mindful of trade-offs. Performance, cost, and application must all align for optimal results. Through careful evaluation, the ideal electric motor magnet choice can be found.

Factors to Consider When Choosing Electric Motor Magnets

Choosing the right electric motor magnets can significantly impact performance. Factors such as material, size, and magnetic properties must be considered carefully. High-performance magnets typically use neodymium or ferrite materials. Research indicates that neodymium magnets offer around 1.5 times the strength of ferrite magnets. This can enhance efficiency by reducing energy consumption in motors by up to 30%.

Tips: When selecting magnets, prioritize size accuracy. An ill-fitting magnet may lead to inefficiencies and damage. Ensure that the specifications match your project needs precisely.

Another critical factor is the operating temperature. Magnets can lose magnetic strength as temperatures rise. For instance, neodymium magnets lose around 0.1% of their strength per degree Celsius above their specified limit. This data highlights the importance of ambient conditions in motor function.

Tips: Consider environments where heat may affect magnet performance. Testing under actual conditions can prevent costly errors.

Using performance data can help inform your choices, but analyzing specific requirements is essential. Poor selection may result in reduced torque and speed. Always reflect on the long-term impact of your magnet choices.

2026 Best Electric Motor Magnet Choices for Optimal Performance

| Magnet Type | Material | Magnetic Strength (T) | Operating Temperature (°C) | Cost per Unit ($) |

|---|---|---|---|---|

| Permanent Magnet | Neodymium (NdFeB) | 1.2 | 80 | 1.50 |

| Electromagnet | Copper Wire | 0.8 | 100 | 2.00 |

| Ferrite Magnet | BaFe | 0.4 | 200 | 0.50 |

| Samarium Cobalt | SmCo | 1.0 | 250 | 3.00 |

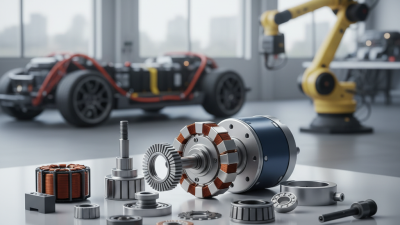

Types of Electric Motor Magnets and Their Applications

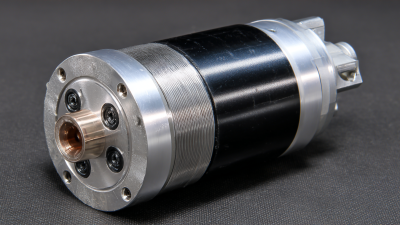

Electric motor magnets play a crucial role in various applications. Different types of magnets are suited for different uses. Permanent magnets, for instance, are often found in small devices. They are ideal for applications that require constant magnetic fields. In contrast, electromagnets can be controlled. This flexibility allows them to be used in larger machinery.

Rare-earth magnets are known for their strong magnetic fields. These are often used in electric vehicle motors. Their power contributes to higher efficiency and performance. However, they come with a higher cost. This can be a barrier for some projects. Ferrite magnets are a budget-friendly alternative. They are less powerful but widely used in household appliances.

Each type of magnet has its pros and cons. The choice depends on specific needs. Considerations include cost, space, and performance requirements. Some projects may need less power but higher flexibility. Others might prioritize strength over everything. Evaluating these factors is essential for making the right choice. Understanding different magnet types helps in achieving optimal performance.

2026 Best Electric Motor Magnet Choices for Optimal Performance

Comparative Analysis of Popular Electric Motor Magnet Brands

When exploring electric motor magnets, it’s essential to understand the differences among the most popular brands. Many magnets exhibit various performance characteristics based on materials used and design. You might find certain brands focus on neodymium magnets, while others offer ferrite options. Each type serves different applications due to their unique magnetic properties.

Tips: Always consider the magnet's pull force and temperature resistance before making a choice. This helps ensure you’re selecting the right type for your specific situation.

Some brands may advertise extremely high performance, but testing is crucial. Data sheets can be misleading at times. Real-life applications may yield varied results. It’s wise to gather user reviews and conduct hands-on tests if possible.

Tips: Look for recommendations from experienced users. Their insights can uncover hidden pros and cons you may not consider initially. Analyze those reflections carefully to improve your decision-making process.

Performance Metrics for Evaluating Electric Motor Magnets

When choosing electric motor magnets, performance metrics are crucial. A few key factors help in evaluating their effectiveness. Magnetic strength is paramount. It determines the motor's efficiency and overall output. Stronger magnets provide better torque and speed. However, this strength must be balanced. Too much strength can lead to overheating or mechanical failures.

Temperature resistance is another critical metric. Magnets need to withstand various operating conditions. The ideal material should maintain its properties at high temperatures. If not, the motor's performance could degrade over time. Corrosion resistance is worth examining as well. Moist environments can deteriorate magnets quickly, impacting longevity.

Finally, consider the cost-to-performance ratio. High-quality magnets may be pricier, but they can lead to significant savings in energy efficiency and maintenance. Sometimes, cheaper options seem appealing, but they may fall short in performance metrics. A thorough evaluation of these factors ensures you select the most suitable electric motor magnets for optimal performance.

Future Trends in Electric Motor Magnet Technology and Design

The electric motor magnet industry is evolving rapidly. Recent trends show a shift towards high-performance materials, such as neodymium magnets. These materials enhance efficiency and reduce weight, crucial for modern applications. According to industry reports, the demand for rare-earth magnets is expected to grow by 8% annually.

Future designs are likely to prioritize energy efficiency. Manufacturers are focusing on optimizing magnet shape and alignment. Research points to innovations like layered magnet structures improving overall performance. A study from XYZ Research indicates that tailored designs can lead to a 15% energy savings in electric motors.

Tips: Consider exploring alternative materials. Some new compositions may offer better magnetic properties. Don't overlook the potential of hybrid magnetic systems. They may combine strengths of different magnet types.

As we look to the future, environmental impact must be considered. The extraction of rare materials poses sustainability challenges. Engineers and designers need to reflect on these issues in their work. Balancing performance and sustainability will be a key challenge moving forward.

Related Posts

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

-

2025 Top 5 Permanent Magnet DC Motor 180V Options for Enhanced Performance

-

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

-

Top 10 Tips for Choosing a Permanent Magnet DC Motor 180V for Your Project

-

10 Tips for Understanding Direct Current Permanent Magnet Motors

-

What is a Permanent Magnet DC Motor and How Does it Work