Top 10 Benefits of Using PMDC Motors in Various Applications

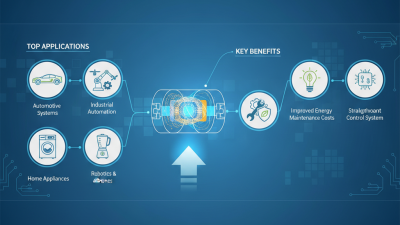

In recent years, PMDC motors have gained immense popularity across various industries. Their efficiency and reliability are hard to overlook. According to Dr. Emily Wang, a leading expert in motor technology, "PMDC motors deliver exceptional torque and performance." This highlights their significance in modern applications.

The benefits of PMDC motors are vast. They are compact, lightweight, and easy to control. This makes them ideal for robotics and automotive applications. However, some users struggle with motor heating issues. Ensuring proper cooling is essential for optimal performance.

Additionally, maintenance might be a concern for some engineers. The design is relatively simple, yet if overlooked, it can lead to problems over time. Despite these issues, PMDC motors remain a popular choice for many. As industries evolve, embracing their strengths can lead to innovation and efficiency.

Key Characteristics of PMDC Motors that Enhance Performance

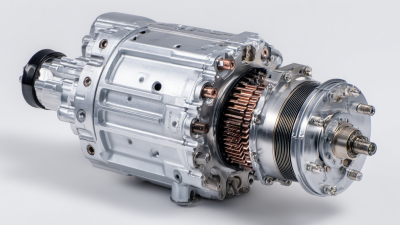

PMDC motors offer distinct advantages across various applications due to their unique characteristics. These motors are known for their compact design and remarkable efficiency. With a typical efficiency rate exceeding 85%, PMDC motors excel in applications requiring optimal power usage. Their simplicity in construction also leads to fewer mechanical failures, resulting in lower maintenance costs. Research shows that more than 60% of industries prefer PMDC motors for applications where reliability is crucial, such as in electric vehicles and material handling.

The torque output of PMDC motors is another significant aspect. These motors produce high torque at low speeds, making them ideal for applications that demand precise control. For instance, in robotic systems, a high starting torque enables quick acceleration. However, this feature can lead to overheating if not managed properly. Users must implement cooling strategies to avoid performance degradation. Furthermore, the absence of brushes in some types allows for smoother operation. Nonetheless, this also raises questions about long-term durability in harsh environments. The choice of appropriate materials is vital in mitigating potential wear and tear.

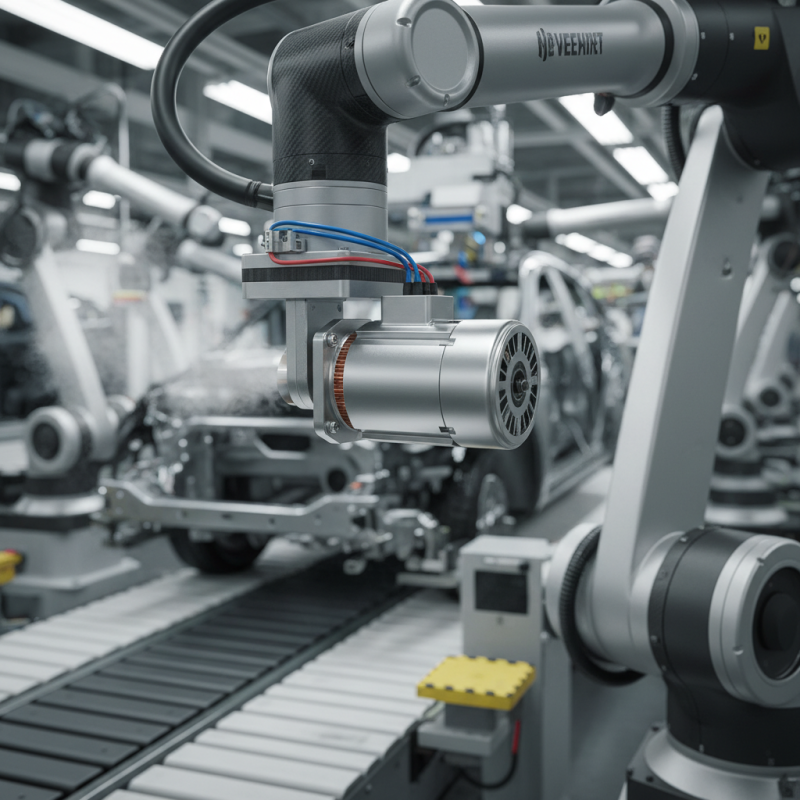

Applications of PMDC Motors in Industrial Automation and Machinery

PMDC (Permanent Magnet Direct Current) motors are increasingly vital in industrial automation and machinery. They offer substantial advantages, particularly in precision control and energy efficiency. According to a recent report by ARC Advisory Group, the use of PMDC motors in automation has risen by 15% in the last five years. This growth highlights their importance across various sectors, including manufacturing and robotics.

In applications requiring speed control, PMDC motors excel. They provide quick response times, making them ideal for conveyor systems and robotic arms. For example, in automated assembly lines, PMDC motors can adjust speed within milliseconds. However, while they are efficient, their performance can be hindered by environmental factors such as extreme temperatures. Motor lifespan may decrease if not managed properly, an aspect that deserves more attention in design discussions.

Another noteworthy application is in precision machining. PMDC motors contribute to the accuracy needed for CNC machines. These motors ensure smooth operation, reducing vibration and wear on components. Nonetheless, custom control systems can be complex and may introduce challenges. Engineers need to weigh the benefits against potential difficulties in integration. The balance between efficiency and reliability remains crucial in real-world applications.

Top 10 Benefits of Using PMDC Motors in Various Applications

| Benefit | Description | Applications |

|---|---|---|

| High Efficiency | PMDC motors have high power-to-weight ratio and energy efficiency. | Robotic arms, conveyor systems |

| Compact Size | Small form factor allows for use in space-constrained applications. | Medical devices, drones |

| Cost-Effective | Lower initial and maintenance costs compared to other motor types. | Manufacturing equipment, HVAC systems |

| Simple Control | Easy to control speed and torque through voltage adjustments. | Automated assembly lines, packaging machinery |

| Quiet Operation | Lower noise levels make them suitable for quiet environments. | Home appliances, office automation |

| High Torque at Low Speed | Provides strong torque even at low speeds, ideal for specific tasks. | Elevators, winches |

| Reliability | Known for long service life and minimal maintenance needs. | Industrial pumps, compressors |

| Versatile Operating Conditions | Can operate effectively in a wide range of environmental conditions. | Outdoor machinery, agricultural equipment |

| Scalability | Easily scalable for different sizes and power requirements. | Custom machinery, varying load applications |

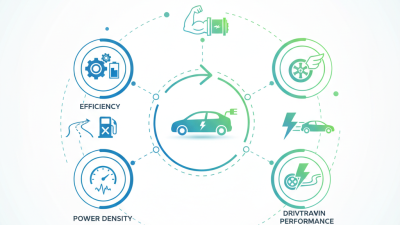

Advantages of PMDC Motors in Automotive and Transportation Industries

The automotive and transportation industries increasingly favor Permanent Magnet Direct Current (PMDC) motors due to their numerous advantages. These motors provide high efficiency, which is crucial for electric vehicles (EVs). A recent report indicated that PMDC motors can achieve efficiencies of over 90%. This efficiency directly translates to reduced energy consumption and lower operational costs.

Reliability is another significant benefit of PMDC motors. They require less maintenance compared to their brushed counterparts. Less maintenance often means reduced downtime. In a market where every minute counts, this can lead to significant cost savings. However, PMDC motors can face challenges in extreme temperatures. Prolonged exposure to high heat may affect their performance, which requires careful consideration in design.

Tips: When selecting PMDC motors for automotive uses, consider the environment in which they will operate. Look for motors rated for high thermal resistance. Another point to note is their size. PMDC motors tend to be more compact, offering design flexibility. This can be a double-edged sword; while compactness is an advantage, it may limit cooling options. Balancing these attributes is essential for optimal performance in transportation applications.

Top 10 Benefits of Using PMDC Motors in Automotive and Transportation Industries

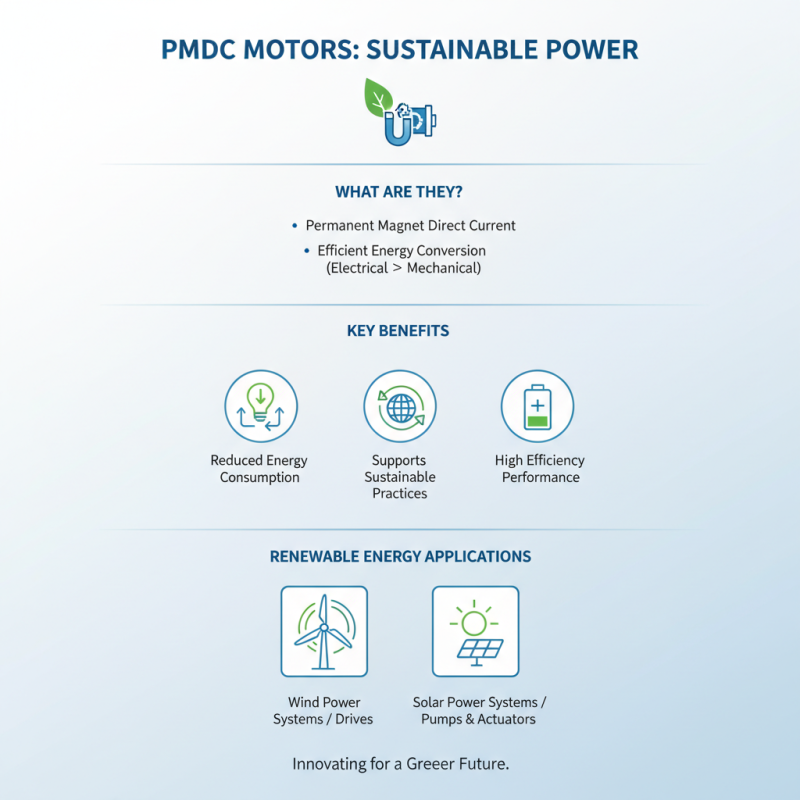

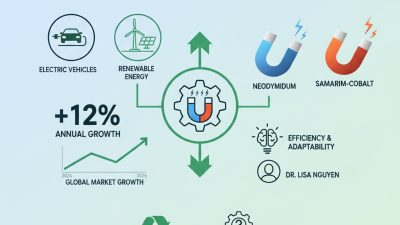

The Role of PMDC Motors in Renewable Energy Solutions

PMDC motors, or Permanent Magnet Direct Current motors, play a crucial role in renewable energy solutions. They offer efficient performance in converting electrical energy into mechanical energy. This efficiency helps reduce energy consumption and supports sustainable practices. In wind and solar power systems, PMDC motors can drive various applications effectively.

These motors are often used in battery-operated devices. They excel in vehicles designed for clean energy. Their compact design allows for easy integration into different systems. However, some users may find that PMDC motors can generate heat. This heat needs to be managed to maintain performance and prevent damage.

Another area of concern is their magnetic field strength, which can weaken over time. This reduction may impact the motor's efficiency. Addressing these issues is essential for maximizing the benefits of PMDC motors. They hold great potential for future innovations in renewable energy, but continuous evaluation and improvement are necessary.

Cost-Effectiveness and Energy Efficiency of PMDC Motors in Use

PMDC motors offer a compelling advantage in terms of cost-effectiveness and energy efficiency. These motors convert electrical energy into mechanical energy with impressive efficiency rates. Many applications benefit from this high efficiency, leading to lower operational costs. Imagine industries where machines run for hours. Saving energy can translate into significant financial relief.

In addition to running efficiently, PMDC motors are comparatively affordable. The initial investment is often lower than that of other motor types. Many businesses find it easier to budget for PMDC motors, allowing for more widespread use. However, some users may overlook maintenance needs. Even energy-efficient motors require occasional attention to keep them running at peak efficiency. Ignoring this can lead to unexpected costs later.

Users often find PMDC motors versatile. They fit various applications, from small appliances to larger machinery. This flexibility makes them a popular choice among engineers. However, they should assess specific application needs. Not all tasks may suit PMDC motors equally well. Balancing performance, cost, and longevity is critical for optimal outcomes.

Related Posts

-

2025 Top PMDC Motor Applications and Benefits You Need to Know

-

2025 Guide: How to Choose the Right PM Stepper Motor for Your Project

-

Top 10 Benefits of Using 3 Phase Permanent Magnet Motor in Industry?

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Why is PMSM Motor the Best Choice for Electric Vehicles Performance

-

Exploring the Best Rotor Magnet Types for 2026 Trends and Innovations?