Top 10 Benefits of Using 3 Phase Permanent Magnet Motor in Industry?

The implementation of 3 phase permanent magnet motors is transforming industrial applications. Recent industry reports highlight a shift towards these motors due to their enhanced efficiency and performance. According to a 2023 study by the International Electromechanical Association, the adoption of these motors can lead to energy savings of up to 30%. This statistic highlights their importance in today's energy-conscious environment.

Experts recognize the potential of 3 phase permanent magnet motors. Dr. Emily Chen, a leading authority in motor technology, states, "The integration of permanent magnet technology is crucial for achieving superior operational efficiency." Her insights underscore the significance of these motors in various sectors, including manufacturing and renewable energy.

As industries strive to improve sustainability, 3 phase permanent magnet motors provide a viable solution. However, the transition is not without challenges. Initial costs and integration complexities can be barriers that companies face. Evaluating the long-term savings versus upfront investments leads to important reflections on modernization strategies in industrial settings.

Key Advantages of 3 Phase Permanent Magnet Motors in Industrial Applications

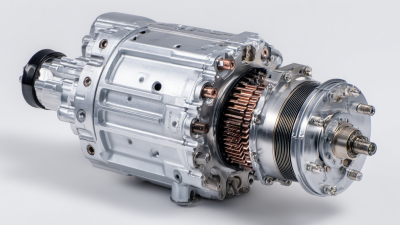

3 Phase Permanent Magnet Motors (PMMs) are increasingly popular in industrial applications. Their efficiency is a game changer. According to research from the U.S. Department of Energy, PMMs can achieve efficiencies exceeding 95%. This high performance reduces energy consumption and results in lower operational costs.

These motors also offer excellent torque density. This enables smaller motor designs without compromising power. Industries can benefit from compact machinery, saving valuable floor space in manufacturing plants. Moreover, PMMs have low maintenance requirements. There are fewer moving parts compared to traditional motors, leading to reduced wear and tear. A report from the IEEE states that maintenance costs drop significantly with the use of PMMs.

Yet, not all is perfect. The initial investment for PMMs can be higher than for conventional motors. This upfront cost might deter some businesses. Additionally, specific applications may not fully exploit the motor’s advantages. Careful evaluation is necessary to ensure the right fit for each industry.

Enhanced Energy Efficiency Compared to Traditional Motors

The use of 3 phase permanent magnet motors is transforming the industrial landscape. One major advantage is their enhanced energy efficiency. Compared to traditional motors, these motors consume less power while delivering more torque. They operate smoothly at various speeds, which reduces energy waste. This efficiency not only lowers electricity costs but also lessens environmental impact.

Tips: To maximize the benefits, consider regular maintenance checks. Keep an eye on the motor's performance. Ensure the right sizing for your application; an oversized motor can lead to energy loss.

Another appealing aspect is their compact design. This feature allows for more space in tight industrial settings. However, installation might be tricky, requiring skilled personnel. Not everyone may find the transition easy. Training staff and ensuring safety standards are crucial for a smooth integration. Evaluate your current systems carefully before making the switch.

Improved Torque and Performance Characteristics

Three-phase permanent magnet motors shine in industrial applications. They deliver improved torque and performance, a critical factor for many machines. With a strong magnetic field, these motors enable faster acceleration. This translates to quicker response times for geared systems. The result? Enhanced production efficiency.

Torque is vital in various industries. It helps in lifting heavy loads and provides smoother operation in complex tasks. These motors offer consistent performance across different speeds. This consistency is important for applications requiring precise control.

However, there can be challenges. For instance, if the motor is oversized, it may lead to energy inefficiency. Proper sizing and application are essential for optimal results.

High efficiency is another benefit, but maintenance remains a concern. While these motors have fewer moving parts, regular inspections are necessary. Wear can still occur, affecting performance. Investing in these motors is wise, but operators must ensure they understand their unique maintenance needs. This combination fosters long-term reliability and a steady workflow.

Reduced Maintenance Needs and Operational Costs

Three-phase permanent magnet motors are gaining traction in various industries due to their efficiency. They operate with reduced maintenance needs. This benefit significantly lowers operational costs. According to a report by the Electrical Engineering Research Institute, maintenance costs can drop by up to 30% when using these motors. This reduction is largely due to fewer moving parts compared to traditional motors.

These motors function with higher efficiency. This leads to less wear and tear over time. Industries report an average of 15% lower energy consumption. When we consider rising energy costs, this can mean substantial savings. Despite these advantages, some facilities still hesitate. They worry about the initial investment, which may seem daunting.

Yet, the long-term benefits often outweigh the initial costs. Indeed, many companies have reported a return on investment within just a few years. Additionally, the reliability of three-phase permanent magnet motors can enhance productivity. However, some users need to rethink their existing systems before transitioning. It's essential to analyze compatibility and integration with current machinery.

Top 10 Benefits of Using 3 Phase Permanent Magnet Motor in Industry

Greater Compactness and Weight Savings in Design

The use of three-phase permanent magnet motors in industry brings significant compactness and weight savings. These motors are generally smaller than traditional types. This leads to more efficient designs in machinery and equipment. A lighter motor can reduce the overall weight of a system. This can simplify transportation and installation.

Moreover, reducing size does not compromise performance. In fact, these motors often deliver higher torque and efficiency. This efficiency can lead to lower energy costs over time. However, some may overlook the potential challenges in heat management. Smaller motors can generate more heat, requiring creative cooling solutions. Companies must assess the thermal aspects closely.

In a competitive landscape, weight savings are vital. Every ounce can impact shipping and operational costs. Designers are constantly seeking ways to maximize functionality without adding bulk. These motors are a step in the right direction, yet one must navigate their limitations. Reflecting on these aspects can lead to better decision-making in motor selection.

Conclusion

The 3 phase permanent magnet motor offers significant advantages in industrial applications, making it an increasingly popular choice among engineers and facility managers. One of its key benefits is enhanced energy efficiency, which surpasses that of traditional motors, leading to lower operational costs and reduced energy consumption. Additionally, these motors exhibit improved torque and performance characteristics, making them suitable for a wide range of demanding tasks.

Moreover, the compact design of the 3 phase permanent magnet motor allows for greater weight savings, facilitating more efficient space utilization in machinery and equipment. This versatility means they can be effectively deployed in various industrial environments, further underscoring their value. With reduced maintenance needs, these motors contribute to lower downtime, ultimately enhancing productivity and profitability in industrial settings.

Related Posts

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Why IPM SYNRM Motors Are Revolutionizing Energy Efficiency in Modern Applications

-

10 Tips for Choosing the Right PMSM Electric Motor for Your Application

-

Top 10 Benefits of Using Permanent Magnet Motors in Modern Applications

-

What is Rotor Magnet and How Does it Work in Electric Motors