Top 10 Benefits of Using a 90V Permanent Magnet DC Motor for Your Projects

When it comes to selecting a motor for various projects, the choice of a permanent magnet DC motor 90V can provide significant advantages that enhance performance, efficiency, and versatility. These motors are known for their compact size and lightweight design, making them an ideal solution for applications where space and weight constraints are critical. With innovative technology that optimizes energy conversion, a permanent magnet DC motor 90V offers high torque and speed control, resulting in superior operational capabilities for both hobbyist and professional uses.

Moreover, the inherent efficiency of permanent magnet DC motors reduces energy consumption, contributing to overall cost savings in long-term operations. Their durability and reliability ensure a longer lifespan, minimizing maintenance needs and increasing productivity. As we delve into the top 10 benefits of utilizing a permanent magnet DC motor 90V, it becomes evident how these motors can revolutionize various projects, from robotics to automotive applications, and more. Understanding these benefits can empower engineers, makers, and innovators to make informed decisions that drive their projects to success.

Understanding the Basics of 90V Permanent Magnet DC Motors

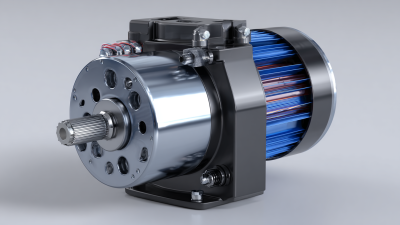

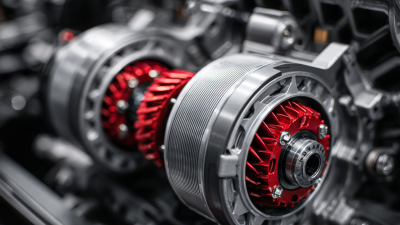

A 90V permanent magnet DC motor is a type of electric motor that utilizes permanent magnets to produce a magnetic field, enhancing its efficiency and performance. These motors are often used in various applications, ranging from automotive systems to industrial machinery. The key characteristic of a 90V motor is its operating voltage, which enables it to deliver high torque and fast acceleration, making it suitable for demanding projects requiring reliable power.

Understanding the basics of 90V permanent magnet DC motors involves knowing their construction and operation. Unlike brushed motors, which rely on mechanical commutation, permanent magnet motors provide smoother operation and longer life due to fewer moving parts. The absence of brushes reduces wear and maintenance needs, while the stable magnetic field from permanent magnets contributes to consistent performance over time. Additionally, these motors are designed for easy integration into electric drive systems, making them a popular choice for developers and engineers looking to optimize their designs.

Key Advantages of 90V Permanent Magnet DC Motors in Various Applications

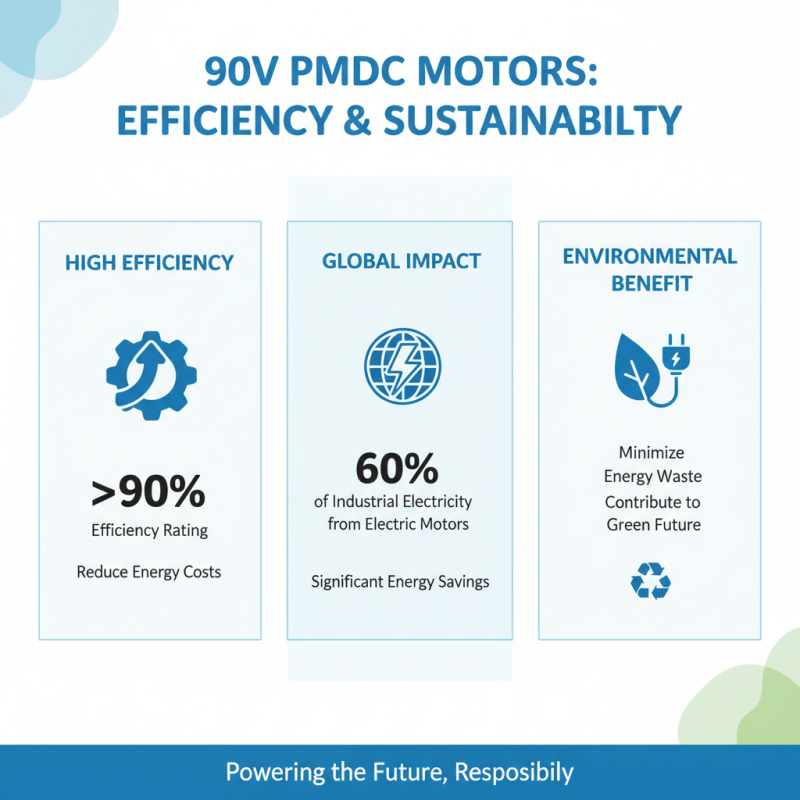

Permanent magnet DC motors (PMDC) operating at 90V have gained popularity across various industries due to their unique advantages. One of the key benefits of utilizing a 90V PMDC motor is their high efficiency. According to a report by the International Energy Agency, electric motors account for approximately 60% of the world's electricity consumption in industrial applications. By implementing 90V PMDC motors, which typically show an efficiency rating above 90%, projects can significantly reduce energy costs and improve overall productivity. This efficiency not only enhances operational performance but also contributes to environmental sustainability by minimizing energy waste.

Additionally, the compact design of 90V PMDC motors allows for easier integration into diverse applications. They are lightweight and offer high torque at low speeds, making them ideal for robotics, automotive, and automation systems. A study published in the Journal of Electrical Engineering highlights that PMDC motors can deliver high starting torque, which is crucial in applications requiring immediate acceleration or heavy load handling. Their versatility enables engineers to leverage these motors in innovative ways, thereby driving advancements in technology and expanding the potential for new projects.

Enhanced Efficiency and Performance Compared to Other Motor Types

Using a 90V permanent magnet DC motor offers numerous advantages over other motor types, particularly in terms of efficiency and performance. One of the standout features of these motors is their ability to maintain high torque at various speeds, which allows them to operate effectively in diverse applications. Their design minimizes energy loss, leading to better overall efficiency compared to traditional induction motors. This enhanced performance can significantly impact project outcomes, especially when precision and immediate response are critical.

Tips for maximizing the efficiency:

- Ensure proper cooling systems are in place to avoid overheating, as excessive heat can diminish performance.

- Using appropriate gear ratios can help in optimizing the motor for specific tasks, allowing for better speed control and power output.

- Regular maintenance checks not only prolong the motor’s lifespan but also ensure it continues to operate at peak efficiency.

Moreover, the compact size of these motors makes them highly versatile, enabling integration into smaller spaces without sacrificing performance. This is particularly advantageous in robotics and high-precision machinery, where size constraints are common. The direct control over speed and torque also empowers hobbyists and engineers alike to experiment and innovate, leveraging the motor’s capabilities to enhance their project designs. By focusing on these aspects, users can fully take advantage of the benefits that a 90V permanent magnet DC motor has to offer.

Versatility and Flexibility for Diverse Project Requirements

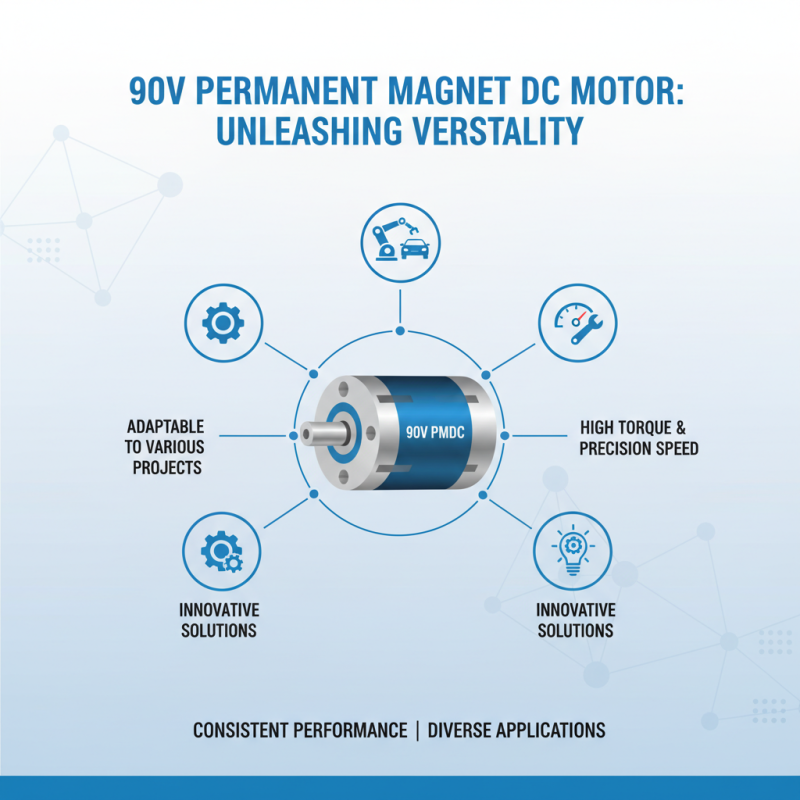

The versatility of a 90V permanent magnet DC motor lies in its ability to adapt to various project requirements across multiple industries. Unlike conventional motors, this type is designed to provide consistent performance in diverse applications, ranging from robotics to automotive systems. Its unique construction enables it to deliver high torque at a wide range of speeds, making it suitable for both high-performance tasks and precision manufacturing processes. This adaptability allows engineers and designers to experiment with innovative solutions without being constrained by the limitations of traditional motor systems.

In addition to flexibility, the 90V permanent magnet DC motor offers ease of integration into different project designs. Its compact size and lightweight nature make it an ideal choice for projects where space is a premium. Furthermore, the efficient energy consumption of these motors contributes to longer operational life and reduced power costs, enhancing their appeal for sustainable practices. By leveraging the strengths of these motors, project developers can achieve improved performance and reliability, ultimately leading to greater success in their engineering endeavors.

Cost-Effectiveness and Long-Term Savings in Motor Projects

When considering motor projects, one of the primary factors is cost-effectiveness. A 90V permanent magnet DC motor is not only an efficient choice but also offers long-term savings that can significantly benefit project budgets. The initial investment in a high-quality motor leads to lower operational costs. These motors typically have lower power consumption, which reduces electricity bills over time. Furthermore, their robust design and minimal maintenance requirements mean fewer expenditures on repairs and replacements, providing additional savings in the long run.

Tips for maximizing cost-effectiveness include proper sizing of the motor for the application, ensuring optimal load conditions. Overloading can lead to premature wear and increased energy costs, so carefully assessing the needs of your project is crucial. Additionally, implementing regular maintenance routines can enhance motor efficiency and longevity.

Another essential aspect is to explore energy recovery options when utilizing these motors in applications like regenerative braking. This not only reduces wasted energy but also extends the lifespan of the motor, thus avoiding replacement costs. By integrating these strategies, you can fully leverage the cost-saving potential of a 90V permanent magnet DC motor in your projects.

Related Posts

-

Top 10 Benefits of Using a Permanent Magnet DC Motor 90V for Your Projects

-

What is a Permanent Magnet DC Motor 90V and How Does it Work

-

Top 7 Benefits of Using Permanent Magnet DC Motors in Modern Applications

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

-

Revolutionizing Robotics: The Essential Role of DC Motor Magnets in Modern Technology

-

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology