Top 10 Benefits of Using Permanent Magnet DC Motors in Modern Applications?

The use of permanent magnet DC motors is steadily increasing in various industries. According to a report by Market Research Future, the global permanent magnet motor market is expected to grow at a compound annual growth rate (CAGR) of 8.23% by 2025. This trend reflects the shift towards energy efficiency and sustainable solutions.

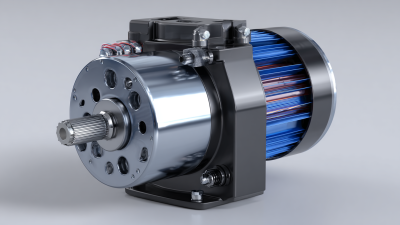

Permanent magnet DC motors offer advantages in performance and efficiency compared to traditional motors. They are lighter and compact, which makes them ideal for many applications like robotics and electric vehicles. However, challenges remain. For instance, high production costs can limit accessibility for some manufacturers. There is also concern about the availability of rare earth materials used in these motors.

Despite these issues, the benefits of permanent magnet DC motors are significant. They provide precise control and high torque at low speeds, making them suitable for demanding applications. This technology is transforming how industries operate. Future improvements and innovations could further enhance their viability in modern applications.

Benefits of High Efficiency in Permanent Magnet DC Motors for Energy Savings

Permanent Magnet DC (PMDC) motors stand out for their high efficiency and energy-saving potential. These motors are designed with powerful magnets that reduce energy loss. They convert electrical energy into mechanical energy more effectively than many alternatives. This means less energy is wasted, which can lead to reduced electricity bills over time.

One striking advantage is the compact size of PMDC motors. Their design allows for efficient operation in limited spaces. This characteristic is vital in modern applications like electric vehicles and robotics. However, the higher initial cost may deter some from investing in them. Many potential users might hesitate due to this upfront expenditure, despite long-term savings.

Moreover, high efficiency doesn't mean they are perfect. Users must consider maintenance needs and specific application requirements. While PMDC motors excel in many scenarios, they might not suit every application. There is still room for improvement in their design and technology. Continued innovation is crucial for even greater efficiency and cost-effectiveness in the industry.

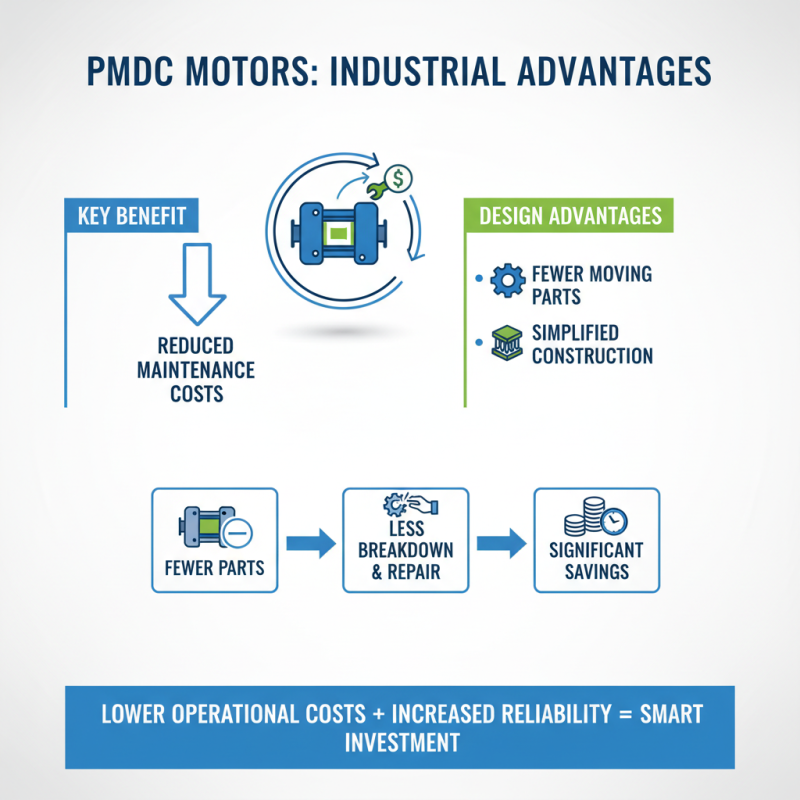

Reduction of Maintenance Costs with Permanent Magnet DC Motors in Industrial Use

Permanent magnet DC motors are widely used in various industrial applications. One of the key benefits is the reduction of maintenance costs. These motors have fewer moving parts compared to traditional motors. This design leads to fewer breakdowns and less frequent repairs. Businesses can save significantly on parts and labor over time.

Operating these motors often requires minimal upkeep. The absence of brushes means less friction and wear. This results in longer motor life and more reliable performance. Companies can allocate their resources elsewhere, enhancing operational efficiency. Yet, it’s crucial to monitor performance regularly. Neglecting maintenance can lead to unforeseen issues.

Tips: Regularly check connections and alignment. This simple step helps in avoiding common problems. Make use of diagnostic tools to assess motor health. Early detection of potential issues can prevent costly downtime. In the long run, proper attention to these aspects can maximize the benefits of using permanent magnet DC motors.

Compact Design Advantages of Permanent Magnet DC Motors in Modern Automation

Permanent Magnet DC Motors (PMDC) are gaining traction in modern automation. Their compact design is a significant advantage. These motors save space in tight applications, making them suitable for various industries. Smaller equipment can lead to lighter machines, enhancing portability. This feature is crucial in robotics and portable devices.

Compactness does not mean low performance. PMDC motors provide high efficiency, leading to lower energy consumption. This makes them an eco-friendly choice. Their design allows for easier integration into existing systems. Fewer components often mean less maintenance. However, it's important to consider heat management. Users must ensure proper ventilation to avoid overheating issues.

Tips: When selecting a PMDC motor, always size your choices carefully. Underestimating power needs can lead to underperformance. Additionally, check for compatibility with your existing control systems. This helps avoid future complications. Keep in mind, the design constraints of your project may require some compromises. Being aware of these limitations can save time and resources.

Enhanced Torque Characteristics of Permanent Magnet DC Motors in Various Applications

The enhanced torque characteristics of Permanent Magnet DC (PMDC) motors are crucial in modern applications. These motors offer a higher torque-to-weight ratio, making them ideal for compact designs where space is limited. In fact, a recent industry report noted that PMDC motors can deliver up to 30% more torque compared to traditional brushed DC motors in similar sizes.

In practical applications, this means that PMDC motors can power more efficient tools and machinery. For instance, in automotive applications, they enable smoother acceleration and deceleration. Many electric vehicles now use PMDC motors due to their quick response times and reliability. However, these advantages do come with certain complexities.

The thermal management of PMDC motors can be challenging. While they are efficient, they can overheat if not properly managed. Engineers must consider heat sinks and cooling solutions to maintain performance. Moreover, as technology evolves, the demand for higher torque at lower speeds is increasing. This creates a need for continuous improvements in motor design and materials. Balancing these factors is essential for maximizing the benefits of PMDC motors in various applications.

Increased Reliability and Longevity of Permanent Magnet DC Motors in Harsh Environments

Permanent Magnet DC (PMDC) motors stand out in tough environments. They operate efficiently at high temperature and humidity levels. Research shows these motors have a lower failure rate compared to traditional motors. A study indicates PMDC motors can last 30% longer in harsh conditions. This increases reliability in sectors like manufacturing and transportation.

Tips: Always provide adequate ventilation. High temperatures can affect motor performance. Regular maintenance checks are essential. They help identify potential issues before they escalate.

Environmental factors matter significantly. Dust and excessive moisture can shorten motor life. PMDC motors are often sealed against these elements. This design keeps internal parts safe. However, operators must remain vigilant. Even robust motors can fail if neglected. Regular assessments of the operational environment are crucial for longevity.

Related Posts

-

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

-

Exploring the Efficiency and Applications of Permanent Magnet DC Motors at 90V

-

What is a Permanent Magnet DC Motor 90V and How Does it Work

-

How to Choose the Right PM Motor for Your Project?

-

How to Choose a Permanent Magnet DC Motor 180V for Your Project?

-

Why Choose a Halbach Array Motor for Your Next Project?