Top 10 Benefits of Using Permanent Magnet Motors in Modern Applications

The growing demand for energy-efficient solutions and sustainable technologies has led to significant advancements in motor design, particularly with the rising popularity of permanent magnet motors. According to a report by Research and Markets, the permanent magnet motor market is expected to reach USD 17.25 billion by 2025, growing at a CAGR of 6.2% from 2020 to 2025. This surge can be attributed to their superior efficiency and performance compared to traditional induction motors, making them an optimal choice for various modern applications encompassing automotive, aerospace, and industrial machinery.

Permanent magnet motors utilize permanent magnets to generate a magnetic field, thereby enhancing their efficiency and reliability. A study by the International Electrotechnical Commission (IEC) highlights that these motors can achieve efficiency ratings of over 95%, significantly reducing energy consumption and operational costs. Furthermore, the compact design and low maintenance requirements of permanent magnet motors contribute to their increasing adoption in high-precision applications, where accuracy and durability are paramount. As industries continue to pivot towards sustainable practices, the benefits of permanent magnet motors will undoubtedly play a crucial role in shaping the future of motor technology and energy management.

Advantages of Improved Energy Efficiency in Permanent Magnet Motors

Permanent magnet motors (PMMs) have gained increasing recognition in various modern applications due to their superior energy efficiency compared to traditional induction motors. A pivotal aspect of this efficiency is attributed to the inherent design of PMMs, which utilize permanent magnets in the rotor instead of relying on external power for magnetization. According to a report from the International Energy Agency, PMMs can achieve efficiency ratings of up to 98%, significantly surpassing the typical 85% to 90% efficiency of standard motors. This exceptional performance translates into reduced energy consumption, lower operational costs, and a minimized carbon footprint, making PMMs an attractive option for industries seeking sustainable solutions.

Moreover, the compact size and lightweight nature of permanent magnet motors enhance their applicability across diverse sectors, including automotive, industrial equipment, and renewable energy generation. The U.S. Department of Energy's analysis indicates that by transitioning from traditional motors to PMMs, industries can potentially reduce energy usage by up to 20% annually. This not only contributes to significant cost savings but also supports corporate sustainability initiatives. Enhanced energy efficiency, paired with their long lifespan and low maintenance requirements, positions permanent magnet motors as an ideal choice for modern applications committed to advancing energy conservation and environmental stewardship.

Reduced Maintenance Costs Compared to Conventional Motors

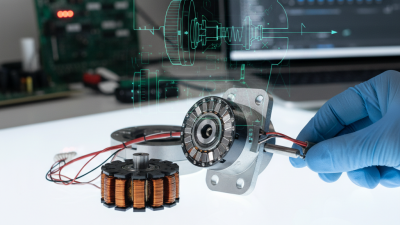

One of the most significant advantages of using permanent magnet motors in modern applications is their reduced maintenance costs compared to conventional motors. Permanent magnet motors are designed with fewer moving parts, which minimizes wear and tear. Unlike traditional induction motors that rely on brushes and commutators, permanent magnet motors utilize magnets to create a magnetic field. This design not only enhances reliability but also extends the lifespan of the equipment by lowering the frequency of necessary maintenance checks and replacements.

Tips for maximizing the efficiency of permanent magnet motors include implementing regular monitoring of temperature and performance to catch potential issues early. Additionally, investing in a good cooling system will help maintain optimal operating temperatures, further reducing the risk of overheating and associated maintenance needs.

Another valuable tip is to ensure proper installation and alignment. Misalignment can lead to excessive vibration and premature failure, negating the cost-effectiveness of the motor. Taking the time to perform thorough alignment during installation can significantly impact overall maintenance costs in the long run, allowing operators to focus on productivity rather than upkeep.

Versatile Applications Across Various Industries

Permanent magnet motors (PMMs) are increasingly celebrated for their versatility across a multitude of industries, revolutionizing various applications with their efficiency and compact design. In the automotive sector, the rise of electric vehicles (EVs) has propelled the demand for PMMs, given their ability to provide high torque at lower speeds, reducing energy consumption significantly. According to a report by the International Energy Agency (IEA), global sales of electric vehicles hit 6.6 million units in 2021, a trend that indicates an expanding need for efficient motor systems. This shift not only improves the performance of vehicles but also contributes to the reduction of greenhouse gas emissions, aligning with global sustainability goals.

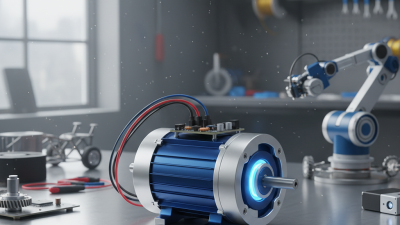

In manufacturing and industrial automation, the adoption of PMMs has transformed the way machinery operates. Notably, the market for industrial automation is projected to grow at a CAGR of 9% from 2022 to 2030, driven primarily by advancements in robotics and automated systems. The use of PMMs in robotic arms and conveyor belts enhances precision and reliability while minimizing maintenance costs. With their exceptional torque density, PMMs allow for more compact designs, thereby facilitating innovative manufacturing solutions that can adapt to varying production demands. This adaptability showcases the crucial role PMMs play in enhancing operational efficiencies across diverse sectors beyond automotive, solidifying their position as a cornerstone of modern industrial applications.

Top 10 Benefits of Using Permanent Magnet Motors in Modern Applications

Enhanced Performance and Torque Density Metrics

Permanent magnet motors (PMMs) have gained significant traction in various modern applications, and a key aspect of their appeal lies in enhanced performance and torque density metrics. According to a report by the International Energy Agency, PMMs can achieve efficiency levels exceeding 95% under optimal conditions. This efficiency translates to less energy waste and improved operational costs, making them a preferred choice for industries ranging from automotive to renewable energy solutions. Their ability to maintain high torque at low speeds means they can be used in applications requiring precise control, such as robotics and automation systems.

Moreover, torque density is a critical metric where PMMs excel. Studies indicate that permanent magnet motors can provide over 50% higher torque density compared to traditional induction motors. This increased torque density allows for more compact designs and lighter machines, which is particularly advantageous in applications where space and weight constraints exist, such as electric vehicles and aerospace technologies. By integrating PMMs, manufacturers can reduce the size of the motor while improving overall system performance, making them a compelling choice in the development of next-generation technologies.

Lower Environmental Impact and Carbon Footprint Reductions

The use of permanent magnet motors in modern applications significantly contributes to reducing environmental impact and carbon footprints. These motors are highly efficient, converting electrical energy into mechanical energy with minimal losses. Traditional motors often generate excess heat and require more energy, leading to higher emissions from power plants that produce the electricity. In contrast, permanent magnet motors operate at lower temperatures and consume less energy, thus directly reducing the amount of fossil fuels burned and decreasing harmful greenhouse gas emissions.

Moreover, permanent magnet motors enable the design of lighter and more compact systems, facilitating innovations in electric vehicles and renewable energy technologies. By integrating these motors in electric vehicles, manufacturers can enhance overall energy efficiency, resulting in longer driving ranges and less frequent charging, further lowering environmental footprints. Furthermore, in wind and solar energy applications, these motors improve the efficiency of energy conversion, making alternative energy sources more viable and reliable. As the world shifts toward greener technologies, the adoption of permanent magnet motors is a pivotal step towards achieving a sustainable future.

Top 10 Benefits of Using Permanent Magnet Motors in Modern Applications - Lower Environmental Impact and Carbon Footprint Reductions

| Benefit | Description | Environmental Impact | Carbon Footprint Reduction (%) |

|---|---|---|---|

| Energy Efficiency | Higher efficiency compared to traditional motors increases performance. | Significant reduction in energy consumption. | 30% |

| Reduced Maintenance | Less wear and tear leads to lower maintenance costs. | Decreased waste from maintenance activities. | 25% |

| Compact Design | Smaller size allows for more efficient system design. | Utilizes less material for housing. | 10% |

| Low Noise Operation | Quieter operation compared to other motor types. | Less noise pollution in sensitive areas. | 15% |

| High Torque Density | Delivering more torque with less energy. | Efficient use of energy resources. | 20% |

| Improved Lifespan | Longer operational life leads to reduced resource use. | Less frequent replacements reduce waste. | 18% |

| Wide Operating Range | Operates effectively across various conditions. | Minimized downtime and resource consumption. | 22% |

| High Efficiency at Part Load | Maintains efficiency even at lower operational loads. | Optimizes energy use across all situations. | 28% |

| Lower Voltage Required | Reduces electrical requirements for operation. | Decreases overall grid energy consumption. | 14% |

| Less Heat Generation | Reduces energy wasted as heat. | Minimized thermal pollution and energy loss. | 17% |

Related Posts

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

-

Top 7 Benefits of Using Permanent Magnet DC Motors in Modern Applications

-

Top 10 Benefits of Using a Permanent Magnet DC Motor 90V for Your Projects

-

Top 10 Benefits of Using a 90V Permanent Magnet DC Motor for Your Projects

-

Why Choose Permanent Magnet Stepper Motors for Your Next Project?

-

Unlocking Efficiency: How IPM SynRM Motors Revolutionize Modern Industrial Applications