Top 10 Best Magnets for Motors to Boost Performance and Efficiency

In the rapidly evolving world of motor technology, enhancing performance and efficiency has become paramount for manufacturers and developers alike. A significant factor contributing to these advancements is the innovation and application of high-quality magnets for motors. According to a report by Markets and Markets, the global permanent magnet market is expected to reach $23.9 billion by 2025, driven by increasing demand for energy-efficient solutions and the growing adoption of electrification across various industries.

As industries shift towards sustainable practices and more efficient energy consumption, the role of magnets in motor applications has never been more critical. High-performance magnets, such as neodymium and ferrite composites, offer superior characteristics in terms of strength, durability, and temperature resistance. These attributes not only enhance the operational efficiency of motors but also reduce energy losses, which can lead to significant cost savings over time.

Furthermore, as electric and hybrid vehicles gain traction, the necessity for robust and efficient motors becomes increasingly pressing. The International Energy Agency projects that the global electric vehicle stock could reach 145 million by 2030, underscoring the essential role that advanced magnets for motors will play in meeting this growing demand. Consequently, understanding the best options available for magnets in motor applications is vital for anyone looking to improve the performance and efficiency of their systems.

Top 10 Magnets for Motors: Enhancing Efficiency and Performance

When it comes to enhancing the performance and efficiency of motors, selecting the right magnets is crucial. A study published by the International Journal of Electrical Engineering & Technology highlights that permanent magnets can increase the efficiency of electric motors by as much as 30%. This significant boost is primarily due to their superior magnetic properties, which lead to higher torque and better overall performance. By utilizing advanced materials such as neodymium or ferrite, manufacturers can produce motors that not only perform better but also consume less energy, aligning with global trends toward sustainability and energy efficiency.

Furthermore, the choice of magnets directly affects the durability and maintenance costs associated with motor operation. Research from the Electric Power Research Institute suggests that optimizing the magnet configuration can reduce energy losses attributable to heat and friction, potentially lowering maintenance expenses by up to 20%. This optimization is especially beneficial in industrial applications where motors operate continuously, emphasizing the importance of selecting high-performance magnets to ensure long-term reliability and efficiency. In summary, investing in the right magnets can lead to substantial improvements in both operational effectiveness and cost savings for motor applications.

Top 10 Magnets for Motors: Enhancing Efficiency and Performance

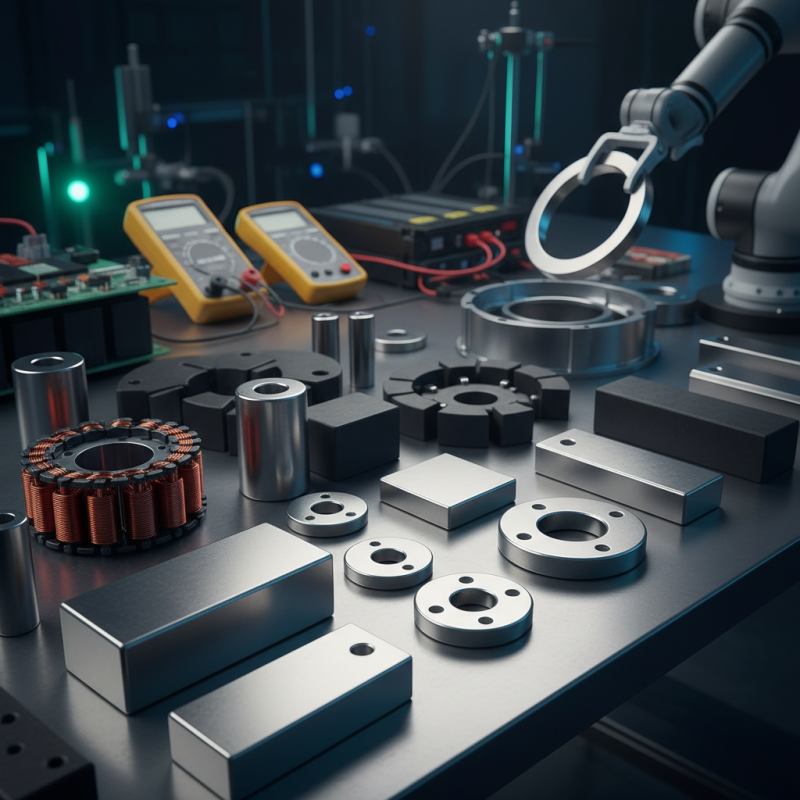

Understanding Magnet Types: Ferrite, Neodymium, and Samarium-Cobalt

When selecting magnets for motors, understanding the different types of magnets available is essential for enhancing performance and efficiency. Three primary categories are ferrite, neodymium, and samarium-cobalt magnets, each characterized by unique properties and applications. Ferrite magnets, composed of iron oxide and other materials, are relatively inexpensive and corrosion-resistant, making them suitable for low-cost applications. Recent industry reports indicate that ferrite magnets can deliver a magnetic energy product between 3 to 5 MGOe (mega gauss-oersteds), which is adequate for applications where strength is not overly critical.

In contrast, neodymium magnets, the strongest commercial magnets available, can achieve energy products exceeding 40 MGOe. Their high magnetic strength allows for smaller and lighter motor designs without sacrificing performance. A study published by the Journal of Advanced Materials highlights that using neodymium magnets can increase the efficiency of electric motors by up to 10–20%, significantly contributing to energy savings and improved overall performance.

Samarium-cobalt magnets, while more expensive, offer exceptional temperature stability and resistance to corrosion. Their energy product typically ranges from 20 to 30 MGOe. This makes them ideal for high-performance applications, especially where motors are subject to harsh environmental conditions. The versatility of these magnets extends their utility in electric vehicles and aerospace applications, as outlined in a recent market analysis, which predicts a growing demand for samarium-cobalt in performance-critical sectors. Understanding these magnet types enables engineers and designers to make informed choices, optimizing motor design for specific applications while maximizing efficiency.

Quantifying Performance: Impact of Magnet Strength on Motor Output

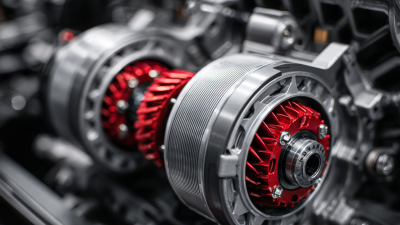

The strength of magnets used in motors plays a crucial role in determining their overall performance and efficiency. Stronger magnets often lead to higher torque and increased power output, enabling motors to operate more effectively under various load conditions. By quantifying the impact of magnet strength on motor output, it becomes clear that optimizing magnet design can significantly enhance a motor's capabilities, making them more suitable for demanding applications.

When selecting magnets for motors, consider the application requirements carefully. Different types of motors may benefit from varying magnet strengths, so it's essential to assess whether you need a high-performance motor for heavy loads or a more efficient one for lighter applications. Additionally, ensure that the selected magnets can withstand the operational conditions, such as temperature and vibration, to maintain their performance over time.

Tips for improving motor efficiency include regularly checking for proper alignment and ensuring that the magnets are correctly positioned. This can prevent unnecessary wear and tear and ensure that the maximum output is achieved. Furthermore, utilizing high-quality materials for the magnet structure can result in better energy conversion, contributing to the long-term performance and durability of the motor.

Case Studies: Magnets in Electric Motors and Their Efficiency Gains

Magnetic components play a crucial role in enhancing the performance of electric motors, with various case studies illustrating their significant impact on efficiency gains. For instance, the incorporation of high-energy density magnets has allowed motors to achieve greater torque while reducing energy consumption. These advancements not only improve the operational efficiency of the motors but also contribute to overall energy savings in various applications, from industrial machinery to electric vehicles.

Another intriguing case study involves the retrofitting of traditional motors with advanced magnetic materials. By replacing conventional magnets with neodymium-based counterparts, engineers observed remarkable improvements in the motors' efficiency ratings. This transition led to a reduction in operational costs and an extended lifecycle of the motors, supporting the trend toward sustainable engineering practices. The combination of innovative magnetic technology and motor design continues to drive enhancements in performance, showcasing the transformative potential of magnets in the realm of electric motors.

Future Trends: Innovations in Magnetic Materials for Motor Applications

Innovations in magnetic materials are transforming the landscape of motor applications, enhancing their performance and efficiency. As technology advances, researchers are developing new types of magnets that boast higher energy densities and improved thermal stability. These advanced materials, such as rare-earth magnets and nanocomposites, provide motors with the necessary power while reducing energy loss. This trend not only optimizes motor functionality but also aligns with the growing demand for sustainability in engineering practices.

When selecting magnets for motor applications, it’s crucial to consider not only the material properties but also their compatibility with the motor's design and intended use. Always seek out magnets with superior resistance to demagnetization and temperature fluctuations. An effective tip for integrating advanced magnets is to ensure proper spacing and alignment within the motor assembly. This can significantly enhance magnetic flux and overall motor efficiency.

Emerging trends like 3D printing of magnetic materials and the exploration of environmentally friendly alternatives are paving the way for future developments in motor technology. As these innovations come to fruition, they promise to further push the boundaries of what’s possible in motor performance. Keeping abreast of these trends can provide valuable insights for optimizing motor design and functionality in various applications.

Top 10 Best Magnets for Motors to Boost Performance and Efficiency

| Rank | Magnet Type | Max Operating Temperature (°C) | Magnetic Strength (MGOe) | Application Area | Future Trends |

|---|---|---|---|---|---|

| 1 | Neodymium Magnet | 80 | 42 | Electric Motors | High-temperature resistant materials |

| 2 | Ferrite Magnet | 250 | 4 | Household Appliances | Improved brittleness |

| 3 | Alnico Magnet | 550 | 8 | Musical Instruments | Sustainability trends |

| 4 | Samarium Cobalt | 300 | 26 | Aerospace | Rare earth recycling |

| 5 | Flexible Magnet | 80 | 3 | Signage | Custom shapes and applications |

| 6 | Bonded Magnet | 120 | 14 | Electronics | Miniaturization trends |

| 7 | Rare Earth Magnet | 200 | 32 | Industrial Applications | Emerging magnetic materials |

| 8 | Injection Molded Magnet | 100 | 12 | Automotive | Cost-effective production methods |

| 9 | Segmented Magnet | 150 | 20 | Wind Turbines | Optimization for efficiency |

| 10 | Ceramic Magnet | 300 | 5 | Various Motors | Trends towards light-weighting |

Related Posts

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

-

Revolutionizing Robotics: The Essential Role of DC Motor Magnets in Modern Technology

-

Top 10 Benefits of Using Permanent Magnet Motors in Modern Applications

-

Top 7 Benefits of Using Permanent Magnet DC Motors in Modern Applications

-

Unlocking Efficiency: How IPM SynRM Motors Revolutionize Modern Industrial Applications

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency