Top 10 Best Permanent Magnet DC Motor 180V Options for Your Projects?

When it comes to selecting a reliable motor for your projects, the permanent magnet DC motor 180V stands out. Its efficiency and performance make it a favorite among engineers and hobbyists alike. These motors are versatile, suitable for various applications, from robotics to electric vehicles.

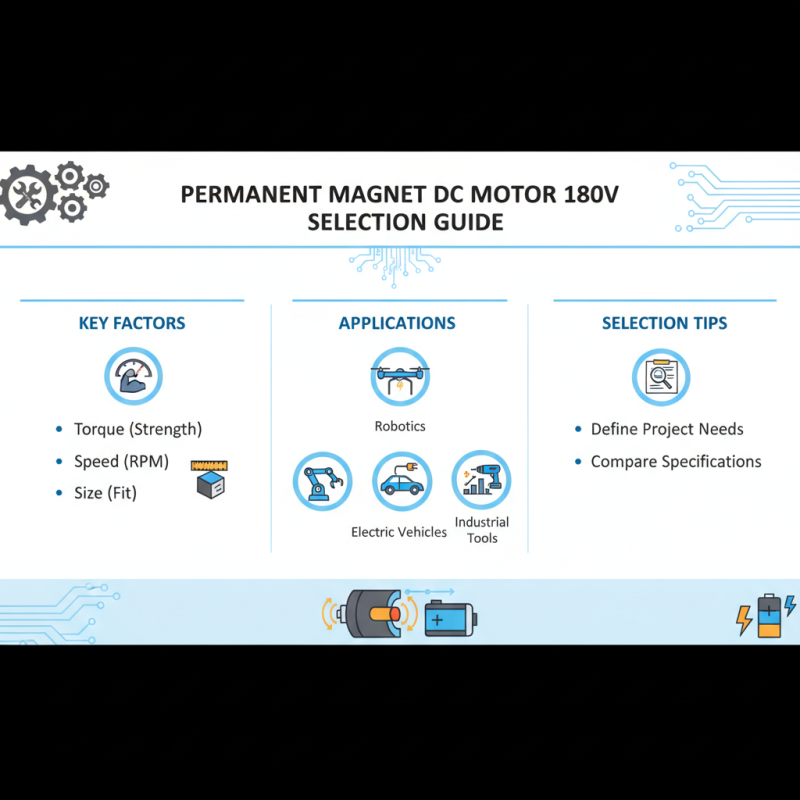

Several options are available on the market, presenting their strengths. However, choosing the right one isn't always straightforward. Factors like torque, speed, and size play crucial roles in decision-making. Often, users overlook the importance of these specifications, leading to less-than-ideal outcomes.

Some motors can be bulky, while others may not deliver sufficient power. It's essential to review your project's requirements thoroughly before making a choice. Many may find the ideal motor on their first try, but others might need several attempts. With this guide, you will navigate the complexities of selecting the best permanent magnet DC motor 180V for your needs.

Understanding Permanent Magnet DC Motors: Key Features and Benefits

Permanent magnet DC motors offer unique advantages, making them a popular choice for various projects. They are compact and lightweight. These motors provide high efficiency and excellent speed control. Most importantly, they operate quietly, making them suitable for applications where noise levels matter.

One key feature of permanent magnet motors is their simplicity. They have fewer components compared to other motor types. This can be an advantage in design and assembly. However, reduced complexity can also lead to challenges in performance tuning. Ensuring optimal operation requires careful planning. Users often find that heat management is crucial to maintain efficiency.

In terms of benefits, these motors provide consistent torque. They are easily integrated into many systems. However, they may have limitations in terms of power output. This could pose a problem in high-demand applications. Understanding these motors' strengths and weaknesses helps in choosing the right one for a specific project. Balancing efficiency and power is often a tricky endeavor.

Criteria for Selecting the Best 180V Permanent Magnet DC Motors

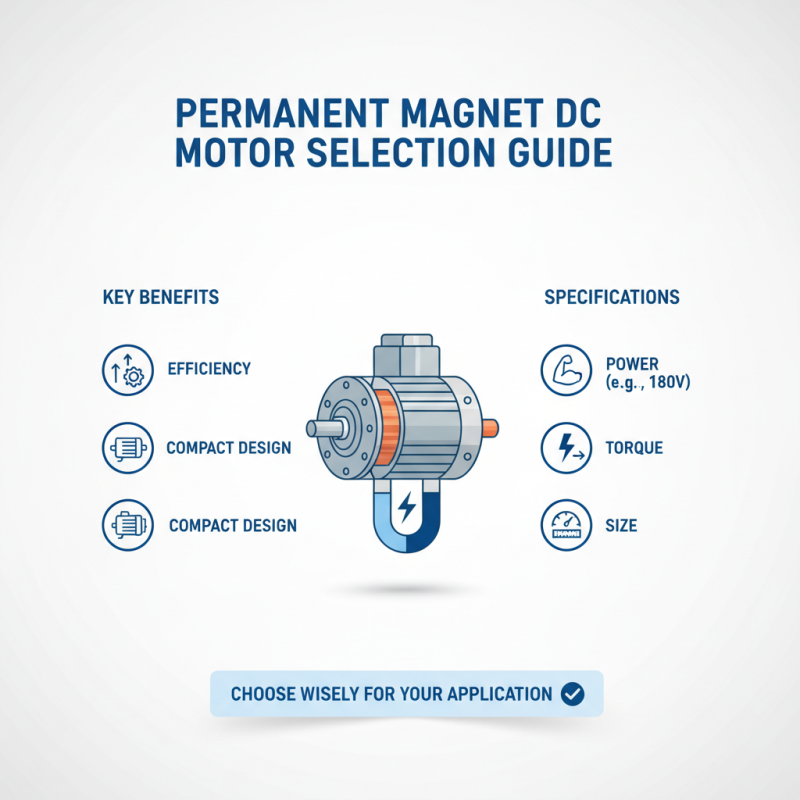

When choosing a 180V permanent magnet DC motor, several key criteria should be evaluated. Efficiency is critical. According to industry reports, high-quality motors can achieve efficiencies exceeding 90%. This not only optimizes energy use but also reduces heat generation. A motor's torque rating is equally important. Torque influences your project's performance. Ensure the motor can handle the load expected during operation.

Another consideration is the motor's size and weight. Compact dimensions allow for easier integration into available spaces. The weight affects mounting and the overall design of your project. Additionally, check the motor’s RPM rating. It dictates how fast the motor can perform. A suitable balance of torque and speed is essential for optimal functionality in applications.

Moreover, not every motor will meet your specific needs. Variability in manufacturing processes may lead to inconsistencies in performance. Be aware of the specifications, especially for continuous use. Certain applications may demand higher durability. Choosing a motor without precise requirements may result in early failure. Review technical sheets thoroughly and reflect on your project's long-term needs. Identifying the right balance between cost and quality is often a challenge.

Top 10 Best Permanent Magnet DC Motor 180V Options for Your Projects

| Motor Model | Rated Voltage (V) | Output Power (W) | No-Load Speed (RPM) | Torque (Nm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 180 | 1500 | 3000 | 5 | 10 |

| Model B | 180 | 2000 | 3500 | 6 | 12 |

| Model C | 180 | 1200 | 2500 | 4 | 8 |

| Model D | 180 | 1800 | 2800 | 5.5 | 11 |

| Model E | 180 | 2500 | 4000 | 7 | 14 |

| Model F | 180 | 1000 | 2400 | 3.5 | 9 |

| Model G | 180 | 2200 | 3300 | 6.5 | 13 |

| Model H | 180 | 1300 | 2600 | 4.5 | 10.5 |

| Model I | 180 | 1700 | 3100 | 5.2 | 11.5 |

| Model J | 180 | 1900 | 3000 | 6 | 12.5 |

Top 10 Permanent Magnet DC Motors: Detailed Reviews and Comparisons

When choosing a permanent magnet DC motor, understanding the specifications is crucial. These motors are known for their efficiency and compact design. A 180V motor can provide substantial power. Many applications benefit from this type. Consider the torque, speed, and size when selecting your motor.

Performance differs among models. The efficiency can vary significantly. Some motors might be too loud for specific projects. Others may overheat if used continuously. It is vital to match the motor with your needs. Pay attention to voltage ratings and current.

Installation requires careful attention. Some motors come with complex wiring. This can confuse beginners. A detailed review of wiring diagrams can help. Testing different motors can be enlightening. You may find one performs better than expected. Each project is unique, and finding the right motor may take time.

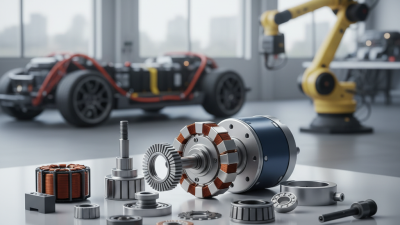

Applications of 180V Permanent Magnet DC Motors in Various Projects

Permanent magnet DC motors operating at 180V offer remarkable versatility in various applications. These motors are widely used in robotics, electric vehicles, and industrial automation. Their efficiency can reach up to 90%, making them an excellent choice for energy-sensitive projects. In a recent industry report, it was noted that demand for high-voltage motors is projected to grow by approximately 7% annually due to advancements in technology.

In robotics, the power and responsiveness of 180V motors enhance performance significantly. They can drive heavy loads while maintaining precision. Furthermore, their compact size allows for integration into tight spaces. Electric vehicles also benefit from these motors. They provide high torque at low speeds, improving acceleration. However, challenges such as heat dissipation and the need for appropriate control systems can arise.

Tips for those considering permanent magnet motors: Always factor in thermal management when designing systems. A well-thought-out cooling solution can prolong motor life. Additionally, consider utilizing feedback systems to improve control accuracy. Remember, not every motor fit will be perfect for all projects. Evaluate the specific requirements to avoid pitfalls in your design process.

Top 10 Best Permanent Magnet DC Motor 180V Options for Your Projects

This chart illustrates the torque output (in Nm) of the top 10 permanent magnet DC motors with 180V ratings. These motors are commonly used in various applications, ranging from electric vehicles to industrial machinery, highlighting the diversity in performance metrics across different models.

Maintenance Tips for Enhancing the Longevity of DC Motors

To enhance the longevity of DC motors, regular maintenance is crucial. Dust and debris can accumulate, leading to overheating or reduced performance. Clean the motor housing regularly. Use a soft brush or compressed air to remove particles. This simple step can prevent major issues and keep the motor running smoothly.

Lubrication also plays a key role. Insufficient lubrication leads to friction and wear. Apply an appropriate lubricant where necessary. This will ensure the bearings function properly and extend the motor's lifespan. Pay attention to any unusual noises. They may indicate wear or need for maintenance.

Monitor the operating temperature. Overheating is a sign of trouble. Ensure proper ventilation around the motor. Sometimes, you may overlook these basic steps, thinking everything is fine. However, small lapses in maintenance can lead to bigger problems down the line. Consider keeping a maintenance log. It can help you track when tasks were last performed and plan future checks.

Related Posts

-

Exploring the Efficiency and Applications of Permanent Magnet DC Motors at 90V

-

Top 10 Benefits of Using a Permanent Magnet DC Motor 90V for Your Projects

-

What is a Magnet Motor Generator and How Does It Work?

-

10 Essential Tips for Choosing the Right Magnets for Motors

-

10 Tips for Understanding Direct Current Permanent Magnet Motors

-

How to Choose the Right IPM SynRM Motor for Your Next Project