2026 Best Rotor Magnet Models for Your Projects?

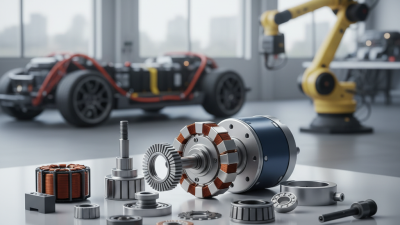

In the world of engineering and design, choosing the right components is critical. Rotor magnets play a pivotal role in various applications, especially in motors and generators. As John Smith, a leading expert in electromagnetism, once said, “The efficiency of your project hinges on the quality of your rotor magnets.” This highlights the significance of making informed decisions.

When considering the best rotor magnet models for 2026, it's essential to look beyond just specifications. It's about finding the perfect balance between performance and cost. Many engineers often overlook this balance. They might choose powerful magnets without considering how that impacts their overall design. The market is flooded with options, making it challenging to identify the right fit for your project.

Furthermore, technology is advancing rapidly. New materials and designs are emerging, promising superior performance. Yet, with these innovations come complexities. Not every new rotor magnet is suitable for every application. It’s crucial to reflect on your specific needs. Avoid getting swayed by marketing gimmicks. In the end, the right choice can differentiate between success and failure in your projects.

2026 Market Trends: Analyzing Rotor Magnet Usage in Various Industries

In 2026, rotor magnets are gaining attention across various industries. The shift toward renewable energy increases their demand in wind turbines and electric vehicles. These magnets are known for their efficiency and power generation capabilities. However, manufacturers face challenges in sourcing materials sustainably. The reliance on rare earth elements raises environmental concerns and ethical questions.

The medical field also sees a surge in rotor magnet applications. They are instrumental in MRI machines, providing clearer imaging. Yet, the precise calibration and quality control are often overlooked. This can lead to inconsistencies in diagnostic results. As industries evolve, the need for innovation in rotor magnet technology becomes crucial. Customization and lightweight designs are in demand, pushing engineers to rethink traditional methods.

Moreover, the electronics sector embraces rotor magnets for their compactness. They enhance performance in small devices, like smartphones and drones. However, many products still lack durability. This creates a cycle of waste that the industry must address. Designers should strive for better materials and longer-lasting solutions. Without this focus, progress may falter.

Key Specifications for High-Performance Rotor Magnets in Engineering

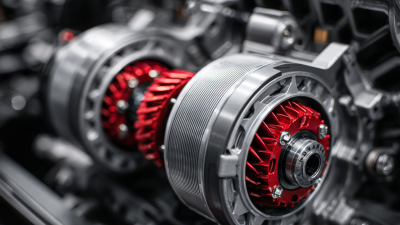

When selecting rotor magnets, key specifications matter greatly. Performance is crucial in engineering projects. You want efficiency and reliability in your designs.

Consider the magnetic strength. Stronger magnets deliver better performance. Assess the temperature resistance as well. Some projects operate in extreme conditions. Choose magnets that maintain their properties under stress.

**Tip:** Always evaluate your project's specific needs. Not all magnets are the same. Check dimensions and weight, too. Compact designs might fit better in tight spaces, but they may lack power.

Another aspect is longevity. Some magnets lose strength over time. Look for specifications that ensure durability. You want a product that stands the test of time.

**Tip:** Testing is essential before finalizing your choice. Prototype different models to see how they perform. Measure effectiveness in your application.

Thinking critically about these factors can guide your decision-making process. Every detail counts for project success. Keep refining your choices for the best outcomes.

Top 5 Rotor Magnet Models: Features, Benefits, and Application Suitability

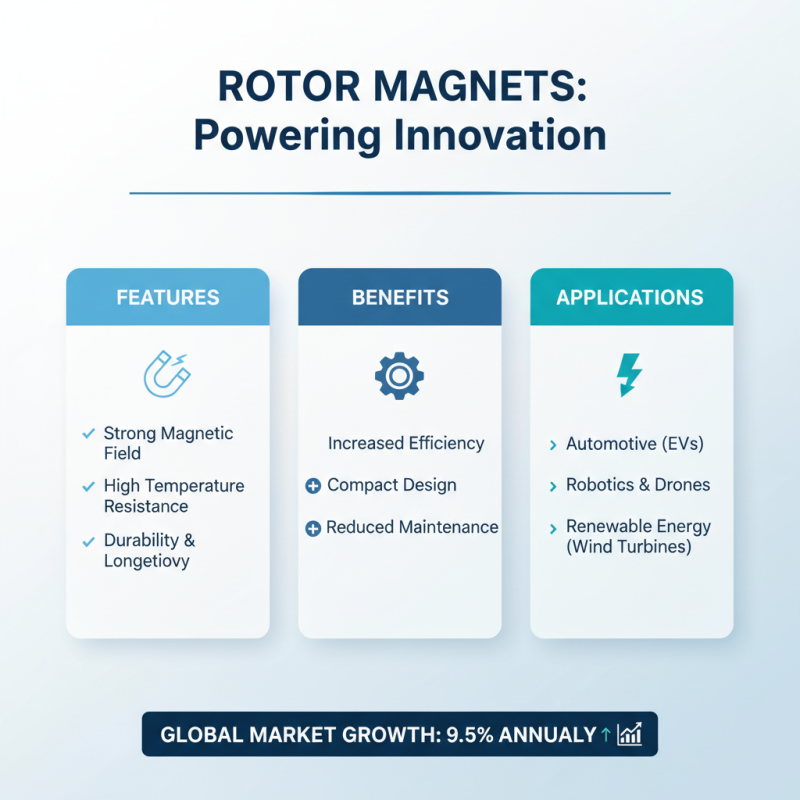

When choosing rotor magnets, understanding their features and benefits is crucial. These magnetic components are essential in many applications, including automotive, robotics, and renewable energy. According to a recent industry report, the global rotor magnet market is projected to grow by 9.5% annually, showcasing their increasing importance.

The top five rotor magnet models each have unique characteristics. For instance, neodymium magnets typically offer high magnetic strength, making them ideal for compact designs. Their applications span from power tools to electric motors. Next, ceramic magnets provide a cost-effective option, suitable for home appliances. However, they have lower magnetic strength compared to neodymium. Rare earth magnets exhibit exceptional durability, yet their higher price can be a drawback for budget-conscious projects.

Another critical aspect is the application suitability of each model. For example, rotor magnets in the wind energy sector must withstand outdoor conditions. Traditional magnets may not endure such environments. There are also reports indicating that improper sizing can lead to inefficiencies. Balancing performance and cost becomes essential for project success. Engaging with specific requirements often uncovers room for improvement in design and material selection.

Comparative Analysis: Cost-Effectiveness of Rotor Magnets in Projects

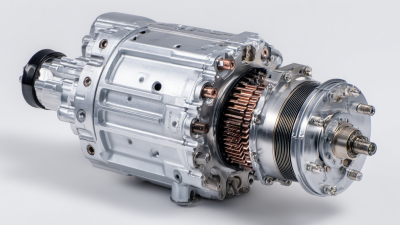

When considering rotor magnets for your projects, cost-effectiveness is crucial. Recent studies indicate that high-performance rotor magnets can enhance efficiency by up to 30%. However, the initial costs of these magnets can be steep. For instance, cheaper alternatives may result in higher operational costs over time. The value proposition must be assessed carefully.

Data from industry reports suggest that while rare-earth magnets often provide superior strength, their price volatility can cause budgeting challenges. In contrast, ferrite magnets, though less efficient, offer significant savings. Their lower cost might appeal to budget-conscious projects. Engineers must weigh these trade-offs. In sectors such as renewable energy, where maximizing output is essential, investing in premium rotor magnets might yield better long-term benefits.

Moreover, lifecycle costs need to be factored in. Frequent replacement of lower-quality magnets can lead to increased downtime. This can affect overall project timelines. Businesses should evaluate the total cost of ownership. The wrong choice could impact project sustainability and efficiency levels. Balancing upfront investment with long-term gains remains a complex decision for project managers and engineers alike.

2026 Best Rotor Magnet Models for Your Projects

| Model | Magnet Type | Size (mm) | Pull Force (N) | Cost ($) | Cost-effectiveness (N/$) |

|---|---|---|---|---|---|

| Model A | Neodymium | 20 x 10 x 5 | 150 | 10 | 15 |

| Model B | Samarium Cobalt | 25 x 15 x 10 | 200 | 25 | 8 |

| Model C | Ceramic | 30 x 20 x 15 | 100 | 5 | 20 |

| Model D | Alnico | 15 x 10 x 10 | 80 | 12 | 6.67 |

| Model E | Neodymium | 40 x 20 x 5 | 250 | 30 | 8.33 |

Future Innovations: Emerging Technologies in Rotor Magnet Designs and Materials

Rotor magnet technology is evolving rapidly. Emerging designs and materials are enhancing performance and efficiency. New alloys and composites promise lighter yet stronger magnets. This shift is crucial for applications in electric vehicles and renewable energy systems. Many researchers are experimenting with rare earth materials, seeking sustainable alternatives. These changes can drive the industry forward.

Informed innovation is key to future designs. Some emerging technologies face challenges. For instance, the cost of materials can be prohibitive. There's also the environmental impact of certain materials to consider. Engineers must balance performance with sustainability. Experimentation with different shapes and sizes is ongoing. Odd configurations might yield unexpected results. It's a complex field, demanding creativity and perseverance.

These advancements offer exciting possibilities. However, more research is needed to solve current limitations. As projects evolve, the demand for better rotor magnets will only grow. Understanding user needs can guide future designs. Collaboration among experts will spark new ideas. The future of rotor magnet technology is full of potential.

Related Posts

-

Top 7 Benefits of Using Permanent Magnet DC Motors in Modern Applications

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Top 5 Benefits of Neodymium Magnet Motors You Need to Know

-

10 Tips for Understanding Direct Current Permanent Magnet Motors

-

Top 10 Tips for Choosing a Permanent Magnet DC Motor 180V for Your Project