Why Choose a Halbach Array Motor for Your Next Project?

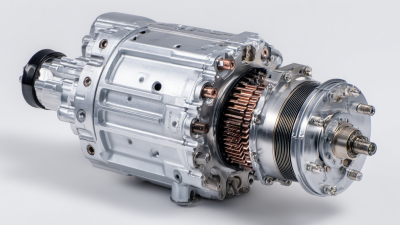

In the realm of advanced motor technology, the Halbach array motor has gained significant attention. This innovative design enhances magnetic efficiency and reduces weight, making it ideal for various applications. Using a Halbach array allows for a more compact motor, which can fit into tight spaces without sacrificing performance.

Many engineers appreciate its unique magnetic configuration. It concentrates the magnetic field on one side while canceling it on the other. This feature improves overall efficiency. However, some may find the complexity of design and manufacturing daunting. It is crucial to weigh the benefits against potential challenges in your specific project.

Considering a Halbach array motor could lead to remarkable advancements in your design. While it offers numerous advantages, remember to reflect on the potential limitations. Each project presents unique demands. Hence, understanding the intricacies of the Halbach array motor is vital for informed decisions.

Understanding the Fundamentals of Halbach Array Motors

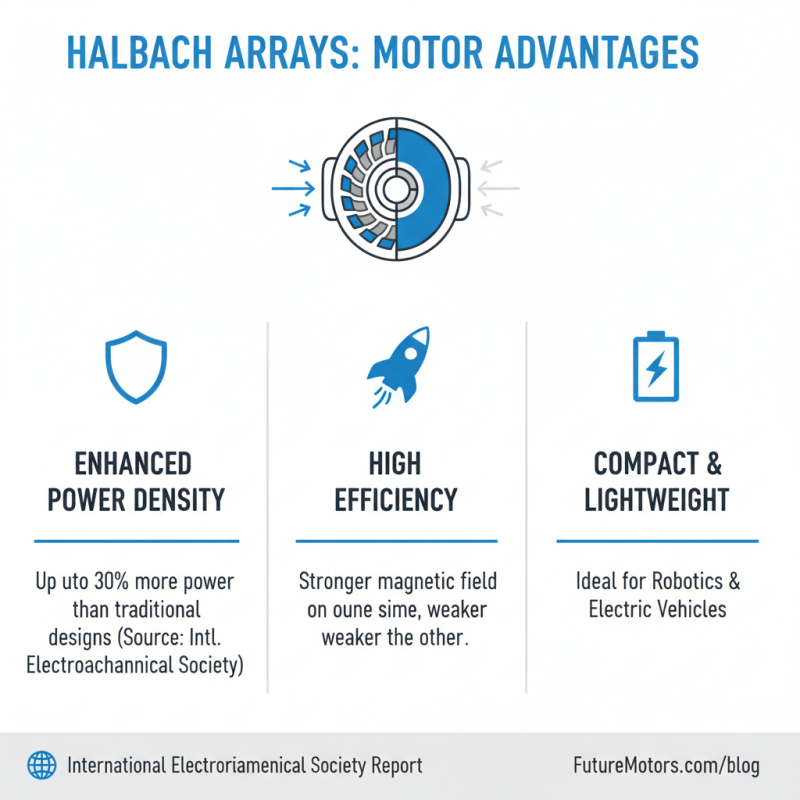

Halbach arrays offer unique advantages for motor design. These specialized configurations of magnets enhance magnetic field strength on one side while canceling it on the opposite side. This feature is crucial for applications requiring high efficiency and compactness. According to a recent industry report by the International Electromechanical Society, Halbach arrays can improve the power density of motors by up to 30% compared to traditional designs. This efficiency is especially beneficial in robotics and electric vehicles, where weight and space are critical.

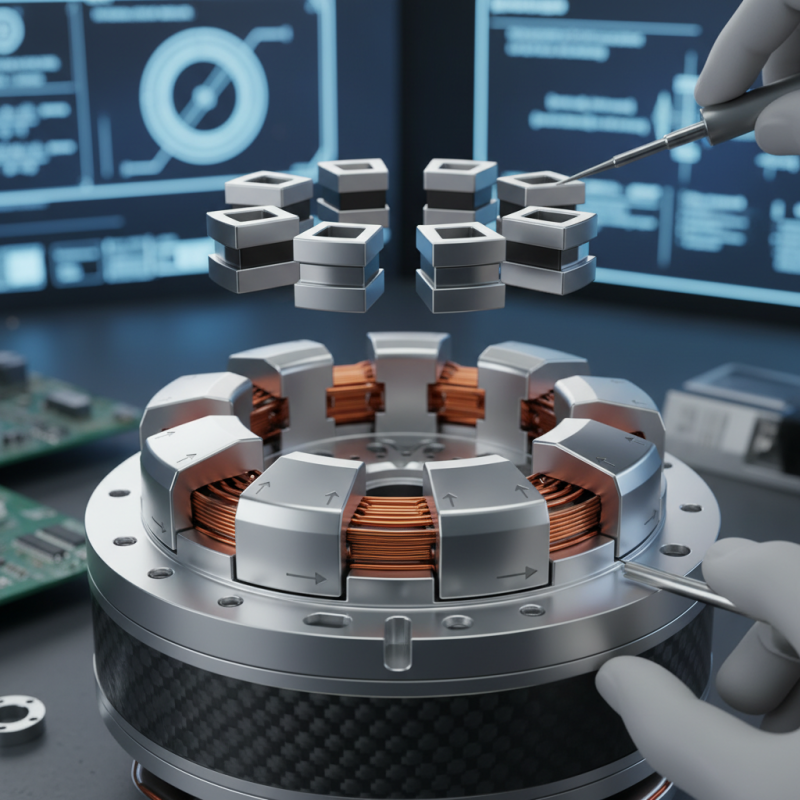

Choosing a Halbach array motor can significantly reduce space requirements. The compact design allows for smaller systems without compromising performance. However, designers must be cautious. Proper alignment of magnets is vital to achieve the desired magnetic effects. Mistakes in assembly can lead to decreased performance.

Tip: Always validate your assembly process with simulations before production. Testing in small batches can reveal hidden issues early. Additionally, understanding the thermal dynamics of your design is crucial. Halbach arrays tend to generate heat, potentially affecting longevity. Regular monitoring and cooling solutions may be necessary. Keep these factors in mind to optimize your project's success.

Advantages of Halbach Arrays Over Traditional Motor Designs

When considering motor design, Halbach arrays stand out. They utilize a unique magnetic arrangement that intensifies the magnetic field on one side while canceling it on the other. This leads to improved efficiency compared to traditional motors. The design offers a compact solution, making it suitable for tight spaces. It’s not just about size; the performance aspect also benefits.

However, these advanced arrays require precise engineering. Each magnet must be carefully aligned for optimal effect. Any small misalignment can hinder performance. Traditional motors often use a simpler design, which can lead to more straightforward assembly. Yet, the trade-off is in the effectiveness of the magnetic field.

Halbach arrays generate a higher torque density. This means more power with less weight, a key advantage for many applications. But, engineers need to weigh the complexity of design against the benefits.

In projects requiring quiet operation, Halbach arrays shine. They reduce vibration, creating a smoother experience. But, building such motors can be challenging. It might involve a steeper learning curve.

There are also considerations regarding the materials used. Designers may need to experiment to find the best components. Overall, while Halbach arrays have great potential, they come with their own set of challenges. Careful thought is essential in choosing the right approach.

Applications and Use Cases of Halbach Array Motors

Halbach array motors are revolutionizing various industries with their unique magnetic configurations. They enhance efficiency and reduce costs in applications ranging from electric vehicles to industrial robotics. According to industry reports, Halbach designs can increase motor torque density by up to 50%. This is significant for robots that require precise and powerful movement.

In the automotive sector, Halbach array motors are being integrated into electric drivetrains. They excel at space utilization, which is crucial in vehicle design. Limiting engine size while maximizing torque output can improve vehicle performance significantly. Additionally, studies show that electric vehicles using these motors can achieve longer ranges due to improved efficiency and less heat loss.

In the realm of consumer electronics, Halbach motors are being used in small, high-performance devices. These applications include drones and portable tools, where weight and size are critical factors. However, integrating Halbach technology can be complex. Designers must navigate challenges in production and material costs. Balancing performance with affordability remains a key consideration.

Design Considerations for Implementing a Halbach Array Motor

When considering a Halbach Array motor, design aspects are crucial. These motors offer a unique magnetic configuration. This enhances efficiency and reduces cogging torque. A study from the IEEE reveals that Halbach Arrays can increase torque density by up to 30%. This allows for smaller, lighter motors. For applications in robotics and electric vehicles, this can lead to significant weight savings.

Another vital factor is the thermal management of the motor. Halbach Array motors can generate more heat due to their efficiency. Proper heat dissipation is essential to maintain performance. An analysis highlighted that designs lacking effective cooling can lose up to 15% of their efficiency. Engineers must consider heat sinks or active cooling systems. This ensures the longevity and reliability of the motor.

Magnetic materials used also impact the final design. High-performance magnets are often essential, but they can increase costs. A balance between performance and budget is necessary. It’s worth noting that not every application needs the high efficiency of a Halbach Array. Sometimes, simpler designs are more practical. An iterative design approach can lead to better results in the long run.

Why Choose a Halbach Array Motor for Your Next Project? - Design Considerations for Implementing a Halbach Array Motor

| Design Consideration | Description | Benefits |

|---|---|---|

| Magnet Configuration | A Halbach array uses a specific arrangement of magnets to enhance magnetic field strength on one side and cancel it on the other. | Increased efficiency and compact design due to minimized magnetic losses. |

| Heat Dissipation | Effective heat management strategies are necessary to maintain performance as Halbach motors can generate heat under load. | Prolongs motor life and improves reliability under continuous operation. |

| Torque Density | Halbach array motors typically provide higher torque densities compared to traditional motors of similar size. | Allows for smaller and lighter designs, which is ideal for applications where space is constrained. |

| Application Suitability | Best suited for applications requiring precision control and high performance, like robotics or electric vehicles. | Enhances performance standards in demanding environments. |

| Cost Considerations | Higher initial costs due to advanced design and materials; requires careful cost-benefit analysis. | Long-term savings through energy efficiency and reduced maintenance costs. |

Future Trends and Innovations in Halbach Array Motor Technology

The Halbach array motor technology is evolving quickly. This innovation leads to better performance and efficiency. One notable trend is the increased use of advanced materials. These can enhance magnetic properties and reduce weight. This change is crucial for applications like electric vehicles and drones.

Another exciting direction is the integration of smart sensors. These sensors can monitor the motor’s performance in real-time. It enables improved diagnostics and predictive maintenance. More importantly, users gain insights into energy consumption and efficiency. This data can drive future enhancements.

Tip: If you're considering a Halbach array for your project, focus on material selection. This choice can drastically affect performance.

Manufacturers are also exploring customization options. Tailoring designs for specific applications can yield significant advantages. However, it’s essential to balance cost with functionality. Not all customizations are worth the investment. Carefully assess what your project truly needs.

Tip: Engage with engineers or experts early in the design process. Their insights can identify potential pitfalls before they become problems.

Related Posts

-

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

-

How to Choose the Right PM Motor for Your Project?

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

-

Top 10 Benefits of Using a 90V Permanent Magnet DC Motor for Your Projects

-

10 Essential Tips for Choosing the Right Magnets for Motors

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems