Why Choose Permanent Magnet Stepper Motors for Your Next Project?

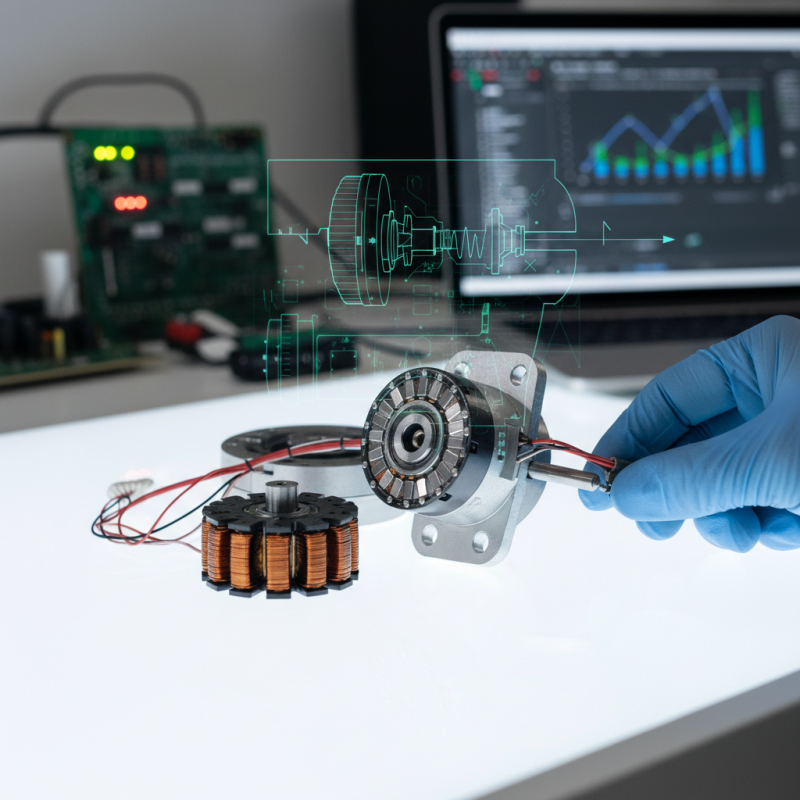

In today's fast-evolving technological landscape, the selection of the right motor for your project can significantly impact its success. Among various options available, the permanent magnet stepper motor stands out due to its distinctive advantages in precision and performance. These motors translate electrical signals into precise mechanical movements, making them an ideal choice for applications requiring high accuracy and reliability.

One of the key benefits of permanent magnet stepper motors is their ability to maintain a constant torque at a wide range of speeds, a feature that simply enhances their versatility across different projects. Furthermore, their design allows for easy control and integration into existing systems, streamlining the development process and reducing overall project costs. As industries increasingly shift towards automation and robotics, understanding and leveraging the capabilities of permanent magnet stepper motors becomes essential for engineers and designers looking to achieve optimal results.

In this discussion, we will explore the compelling reasons to choose permanent magnet stepper motors for your next project, examining various factors such as efficiency, performance, and adaptability, which collectively make these motors an indispensable asset in modern engineering applications.

Benefits of Using Permanent Magnet Stepper Motors in Automation Projects

Permanent Magnet Stepper Motors (PMSMs) are increasingly being recognized for their advantages in automation projects. One of the key benefits of using PMSMs is their high torque at low speeds, which makes them ideal for applications that require precise positioning and control. Their ability to maintain torque even when stationary ensures that tasks such as CNC machining and robotics can be executed with remarkable accuracy. Additionally, PMSMs typically provide smoother motion and reduced vibration compared to other types of motors, leading to improved overall performance of automated systems.

When considering PMSMs for your next project, it’s important to keep in mind a few tips. First, assess the specific requirements of your application, including load characteristics and speed ranges, to select a motor that offers optimal performance. Ensure that the control system you plan to use can effectively manage the motor’s unique capabilities. Lastly, consider the thermal management of your motor, as overheating can adversely affect performance and lifespan.

Another critical aspect to consider is the integration of PMSMs within your existing systems. They are inherently compatible with modern control technologies, which can streamline the design and programming process. This compatibility allows engineers to leverage advanced features such as closed-loop control, enhancing both the reliability and efficiency of the automation setup. By taking these factors into account, you can fully harness the potential benefits that Permanent Magnet Stepper Motors offer in your automation projects.

Key Performance Metrics of Permanent Magnet Stepper Motors Compared to Alternatives

Permanent magnet stepper motors (PMSMs) have become increasingly popular in various applications due to their superior performance metrics compared to alternatives like DC or AC motors. One of the standout features of PMSMs is their high precision and repeatability, which is crucial in applications such as robotics and CNC machinery. According to a report by the International Society of Automation, PMSMs can achieve step accuracy as high as 0.9 degrees, making them ideal for applications requiring intricate movements. Additionally, their torque characteristics show a significant advantage, with PMSMs providing a consistent holding torque even when stationary, effectively outperforming their brushless and brushed counterparts in similar scenarios.

Another critical performance metric is the efficiency of permanent magnet stepper motors. A study published by the IEEE Transactions on Industry Applications indicates that PMSMs can operate with efficiencies exceeding 85%, compared to typical efficiencies of 60-70% for traditional DC motors. This increased efficiency not only translates to lower energy consumption but also results in reduced heat generation, leading to longer operational life and less need for complex cooling solutions. Furthermore, the compact design of PMSMs allows for lighter and more space-efficient assemblies, which is a vital consideration in design-heavy industries such as aerospace and automation. These performance metrics highlight why engineers and designers are increasingly turning to permanent magnet stepper motors for their projects.

Cost Analysis: Long-Term Savings with Permanent Magnet Stepper Motors

When considering a project that requires precision and reliability, permanent magnet stepper motors (PMSMs) stand out not only for their performance but also for their long-term cost effectiveness. A recent study by the International Electrotechnical Commission (IEC) highlighted that PMSMs exhibit an efficiency rate exceeding 85%, which translates to reduced energy costs over the lifecycle of the motor. This high efficiency means less energy is wasted as heat, allowing for lower operational costs, particularly in applications that require continuous usage.

Furthermore, the maintenance requirements for PMSMs are significantly lower than those for traditional motors. According to the American Society of Mechanical Engineers (ASME), routine maintenance costs can account for 15-20% of a project's total operating expenses. Since PMSMs have fewer moving parts and do not require brushes like their brushed counterparts, the decrease in wear and tear leads to extended lifespan and reduced maintenance frequency. This results in substantial savings over time, making PMSMs a wise investment for projects aiming for both high performance and cost efficiency.

Applications of Permanent Magnet Stepper Motors in Robotics and CNC Machines

Permanent magnet stepper motors have become increasingly vital in the fields of robotics and CNC machines due to their precision, reliability, and efficiency. In the robotics sector, these motors enable accurate positioning and smooth motion control, which are essential for tasks such as assembly, pick-and-place operations, and robotic simulations. According to a report by ResearchAndMarkets.com, the global robotics market is projected to grow at a CAGR of 26.9%, driving demand for advanced actuation systems like permanent magnet stepper motors. Their ability to deliver high torque at low speeds and to maintain position without the need for feedback systems makes them particularly suited for robotic applications where precision is critical.

In CNC machines, permanent magnet stepper motors play a crucial role in enhancing machining processes by allowing for precise control of tool movements. They enable complex machining tasks, such as milling and engraving, to be performed with high accuracy. A study published by the International Journal of Advanced Manufacturing Technology indicates that the adoption of stepper motors in CNC applications can reduce cycle time by up to 30%, significantly improving operational efficiency. Additionally, these motors enhance the performance of CNC systems by providing consistent torque across various speeds, leading to better quality output and reduced wear on the machinery.

Why Choose Permanent Magnet Stepper Motors for Your Next Project?

| Application | Motor Type | Torque Rating (Nm) | Step Angle (degrees) | Voltage (V) | Current (A) |

|---|---|---|---|---|---|

| 3D Printing | Bipolar Stepper | 0.48 | 1.8 | 12 | 1.5 |

| Robotic Arms | Unipolar Stepper | 0.5 | 1.8 | 24 | 1.2 |

| CNC Machining | Hybrid Stepper | 0.8 | 1.8 | 48 | 2.0 |

| Food Processing | Bipolar Stepper | 0.35 | 1.8 | 12 | 1.0 |

| Laser Engraving | Unipolar Stepper | 0.6 | 1.8 | 24 | 1.4 |

Technical Specifications and Efficiency Ratings of Permanent Magnet Stepper Motors

Permanent magnet stepper motors are increasingly favored in various automation and control projects due to their impressive technical specifications and efficiency ratings. These motors typically operate with a high step resolution and can achieve precise positioning without the need for feedback systems. Their torque is consistently high across a wide range of speeds, making them ideal for applications where maintaining performance under load is crucial. Additionally, these stepper motors can run at high frequencies, which enables rapid acceleration and deceleration – a significant advantage in fast-paced environments.

When selecting a permanent magnet stepper motor, it’s essential to consider factors such as holding torque, step angle, and power consumption. Holding torque is particularly critical; it determines the motor’s ability to resist external forces when stationary. A smaller step angle often translates to higher precision, allowing for finer control in applications requiring detailed movements. Moreover, examining the power consumption ratings can help maximize energy efficiency, contributing to longer operational lifespans and reduced operational costs.

Tips: Always match the motor specifications to your project requirements. Ensure that the motor's current rating aligns with the power supply you plan to use, as this can affect both performance and efficiency. Additionally, consider integrating adequate cooling mechanisms to maintain optimal operating temperatures, especially in high-load applications.

Related Posts

-

10 Tips for Choosing the Right PMSM Electric Motor for Your Application

-

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

-

Why is PMSM Motor the Best Choice for Electric Vehicles Performance

-

Top 10 IPM Motors: Best Options for Efficiency and Performance in 2023

-

Why IPM SYNRM Motors Are Revolutionizing Energy Efficiency in Modern Applications

-

Unlocking Efficiency: How IPM SynRM Motors Revolutionize Modern Industrial Applications