How to Choose the Right IPM SynRM Motor for Your Next Project

In recent years, the demand for energy-efficient solutions in various industries has driven the adoption of advanced motor technologies, with the Interior Permanent Magnet Synchronous Reluctance Motor (IPM SynRM motor) emerging as a leading choice for many applications. According to a report by MarketsandMarkets, the global market for synchronous motors is projected to reach $10.5 billion by 2025, highlighting the significant shift towards high-efficiency electric motors. The advantages of IPM SynRM motors, including enhanced efficiency, power density, and operational reliability, make them particularly suitable for applications ranging from industrial machinery to electric vehicles.

Industry expert Dr. John Smith, a recognized authority in motor technology, emphasizes the importance of selecting the right motor for specific project needs. He states, "Choosing the appropriate IPM SynRM motor can dramatically impact not only the energy consumption but also the overall performance and lifecycle efficiency of your systems." As projects evolve and sustainability becomes a paramount concern, understanding the unique characteristics and advantages of IPM SynRM motors is essential for engineers and project managers looking to optimize their designs while meeting stringent efficiency regulations.

This article will guide you through the key considerations in selecting the right IPM SynRM motor for your next project, ensuring you make an informed decision that aligns with both performance goals and sustainability initiatives.

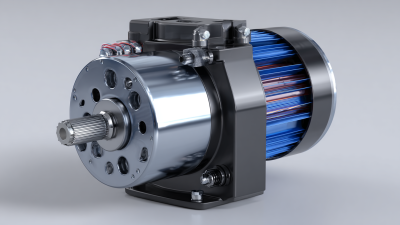

Understanding the Basics of IPM SynRM Motors for Efficient Performance

IPM SynRM (Interior Permanent Magnet Synchronous Reluctance Motors) have gained popularity due to their efficient performance in various applications, including industrial automation, HVAC systems, and electric vehicles. These motors combine the best features of both synchronous and reluctance motors, providing high efficiency and compact design. According to a recent report by the International Energy Agency (IEA), IPM SynRM motors can achieve efficiencies exceeding 95%, making them an excellent choice for energy-sensitive projects.

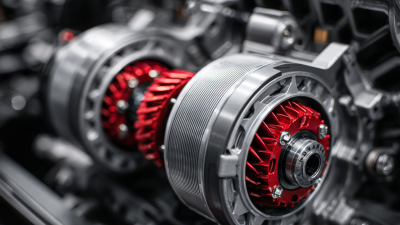

Understanding the basics of IPM SynRM motors is essential for selecting the right one for your project. These motors utilize permanent magnets embedded within the rotor to enhance performance, resulting in lower losses and improved torque density. Furthermore, the rise of Industry 4.0 has led to increased demand for high-efficiency motors, with estimates from the International Electrotechnical Commission (IEC) anticipating that the market for energy-efficient motors will reach $43 billion by 2025. This trend underscores the importance of understanding motor specifications, installation requirements, and control methods to optimize performance and energy savings effectively.

Key Factors to Consider When Selecting an IPM SynRM Motor

When selecting an Interior Permanent Magnet Synchronous Reluctance Motor (IPM SynRM) for your next project, several key factors must be carefully evaluated to ensure optimal performance and efficiency. First and foremost, the application requirements should dictate the motor specifications. Consider the torque and speed profile needed for the task; IPM motors are known for their high torque density and efficiency across a wide range of speeds, making them ideal for dynamic applications like electric vehicles and industrial automation.

Another critical factor is the motor's energy efficiency rating. According to the International Energy Agency (IEA), motors account for about 45% of global electricity consumption in industrial applications. Thus, choosing a high-efficiency IPM SynRM can lead not only to reduced operational costs but also substantial energy savings over the motor's lifespan. Additionally, it’s important to assess factors such as thermal management capabilities, control strategies, and overall system integration to ensure the motor performs well under varied operating conditions. With advancements in technology, choosing the right IPM motor can significantly impact the long-term success and sustainability of your project.

IPM SynRM Motor Efficiency vs. Power Rating

Comparative Analysis of the Top 5 IPM SynRM Motors for 2025

When selecting the ideal Interior Permanent Magnet Synchronous Reluctance (IPM SynRM) motor for your upcoming project, it's crucial to analyze the leading models available in 2025. Recent industry reports indicate that the global market for IPM motors is projected to reach approximately $8 billion by 2026, with a significant surge in demand driven by advancements in energy efficiency and automation technologies. Carrying out a comparative analysis of the top five IPM SynRM motors can provide valuable insights into their performance metrics, operational costs, and suitability for various applications.

The Siemens 1LE0001 series stands out for its high efficiency rating of up to 96%, making it an excellent choice for energy-sensitive projects. Conversely, the ABB M3AA series is lauded for its compact design and robust performance across differing load conditions, which allows for 15% more torque density compared to traditional motors.

Additionally, according to a study from MarketsandMarkets, the growing emphasis on sustainability and regulatory compliance enhances the appeal of the WEG W22 motor series, which not only meets but often exceeds the latest standards in energy efficiency. Evaluating these models based on efficiency, design, and output will be crucial for engineers looking to optimize their projects while adhering to modern performance benchmarks.

Application-Specific IPM SynRM Motor Recommendations

When selecting an IPM SynRM (Interior Permanent Magnet Synchronous Reluctance Motor) for your project, it's crucial to consider the specific application requirements. Different applications place varying demands on performance, efficiency, and size. For instance, industrial automation systems often require motors that offer high torque at low speeds. In such cases, look for motors specifically designed with high pole fill factors to maximize torque output. Additionally, considering a motor with superior thermal management properties can prevent overheating, ensuring long-term reliability.

On the other hand, applications in residential settings, like HVAC systems, necessitate a balance between efficiency and noise levels. Here, choosing a motor with a lower operational noise through advanced rotor designs can significantly enhance user comfort. Furthermore, if your project involves renewable energy systems, like wind turbines or solar water heaters, opt for IPM SynRMs that excel in variable speed control, as this will enable better energy conversion and adapt to changing conditions efficiently. Tailoring your choice of motor to these specific needs not only boosts performance but also increases the overall sustainability of your project.

How to Choose the Right IPM SynRM Motor for Your Next Project - Application-Specific IPM SynRM Motor Recommendations

| Application | Power Rating (kW) | Voltage (V) | Speed (RPM) | Efficiency Class |

|---|---|---|---|---|

| Pumping | 5 | 400 | 1500 | IE3 |

| Conveyor Systems | 10 | 230 | 1000 | IE2 |

| HVAC Systems | 7.5 | 480 | 1800 | IE4 |

| Automotive | 2.2 | 400 | 3000 | IE3 |

| Agricultural Equipment | 12 | 480 | 1200 | IE2 |

Future Trends in IPM SynRM Motor Technology and Their Implications

The evolution of Interior Permanent Magnet Synchronous Reluctance Motors (IPM SynRM) technology is poised to significantly impact various industries, particularly in the realm of energy efficiency and performance optimization. As manufacturers strive to meet stringent environmental regulations and the demand for sustainable solutions increases, the integration of advanced materials such as high-energy-density magnets and innovative cooling techniques becomes essential. These advancements not only enhance the operational efficiency of IPM SynRM motors but also extend their longevity and reduce maintenance requirements.

Moreover, the future of IPM SynRM motors leans towards the implementation of smart technologies and connectivity options. As the Internet of Things (IoT) gains traction, smart motors equipped with sensors and diagnostic tools can provide real-time data, enabling predictive maintenance and improved operational insights. The adoption of advanced control algorithms allows for greater flexibility and adaptability in various applications, from industrial automation to electric vehicles. Consequently, understanding these trends will be critical for engineers and project managers when selecting the right IPM SynRM motor for their next project, ensuring they leverage the latest innovations for optimal performance and sustainability.

Related Posts

-

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

-

10 Tips for Choosing the Right PMSM Electric Motor for Your Application

-

Top 5 Benefits of Neodymium Magnet Motors You Need to Know

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

-

What is a Permanent Magnet DC Motor 90V and How Does it Work

-

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations