How to Choose a Permanent Magnet DC Motor 180V for Your Project?

Choosing the right motor is critical for any project. For many applications, a permanent magnet DC motor 180V stands out. These motors offer high efficiency and compact designs. According to a report by the International Electromechanical Association, the market for DC motors is expected to grow significantly, reaching over $10 billion by 2025.

Experts emphasize the importance of selecting a suitable motor. Dr. Alice Thompson, a renowned motor specialist, once stated, “The right motor selection can make or break a project.” This highlights the significance of understanding motor specifications and applications.

A permanent magnet DC motor 180V can provide excellent performance. However, selecting the ideal model can be challenging. Factors like load requirements and environmental conditions must be navigated carefully. A common pitfall is assuming all motors are interchangeable. This can lead to inefficient operations or project failures. Understanding these details creates opportunities for better designs and outcomes.

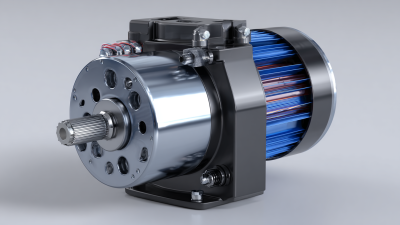

Understanding the Basics of Permanent Magnet DC Motors

Permanent magnet DC motors (PMDC) are popular for various applications. They offer simplicity and efficiency. Understanding their basics is crucial before making a decision.

PMDC motors operate using magnets to generate a magnetic field. This differentiates them from other motor types. They rely on permanent magnets instead of electromagnets. As a result, they can be smaller and lighter. This is beneficial in space-constrained projects. Another important factor is the voltage rating. A 180V PMDC may seem high, but it can provide significant power output.

When selecting a motor, consider torque and speed requirements. Do you need high starting torque or constant speed? It's a question worth pondering. Also, be aware of thermal limitations. Overheating can lead to failures. Choosing an appropriate model might require multiple attempts. Testing different motors can provide valuable insights. Ultimately, understanding your specific needs can lead to better choices.

Key Specifications to Consider for 180V Permanent Magnet DC Motors

When choosing a 180V permanent magnet DC motor, understanding key specifications is essential. Voltage ratings determine the power output. Always ensure the motor’s voltage aligns with your project requirements. Overloading a motor can lead to failure. Pay attention to the current ratings as well. Higher currents indicate smoother operation but may require better heat management.

Torque is another critical specification. This determines how much force the motor can exert. A higher torque is beneficial for tasks requiring heavy lifting. Consider the speed ratings too. This tells you how fast the motor can operate under load. Matching speed to your project demands can be tricky.

Efficiency ratings often get overlooked. A more efficient motor leads to energy savings. However, sometimes more efficient seems less powerful. It’s crucial to find a balance between efficiency and performance. Endurance factors, like insulation class and operational lifespan, should also meet your needs. All these details can feel overwhelming, but they significantly impact your final choice.

Assessing Your Project Requirements for Motor Selection

When selecting a permanent magnet DC motor, it's crucial to evaluate your project's specific needs. Consider the voltage requirement first. For a 180V motor, assess the power supply available in your setup. Will it be able to consistently provide this voltage? Too often, users overlook this aspect and later face performance issues.

Next, think about the torque and speed requirements. Different applications demand varying torque levels and speeds for optimal performance. For instance, a robotics project might need higher torque for lifting objects, while a fan might prioritize speed. Some may take estimates too lightly, risking inefficient operation. What are the exact figures you need?

It’s also important to reflect on the physical space where the motor will fit. Size constraints can affect your choice and lead to unforeseen complications. Make sketches of your layout. Consider heat dissipation. Will the motor get too hot? Overheating can reduce efficiency and lifespan. Some might not realize this until it’s too late. Identifying these factors before making a decision can save you time and frustration.

How to Choose a Permanent Magnet DC Motor 180V for Your Project?

| Parameter | Specification |

|---|---|

| Voltage | 180V |

| Rated Power | 2kW |

| No-load Speed | 3000 RPM |

| Continuous Current | 12A |

| Torque Constant | 0.1 Nm/A |

| Efficiency | 85% |

| Frame Size | 180mm |

| Weight | 15 kg |

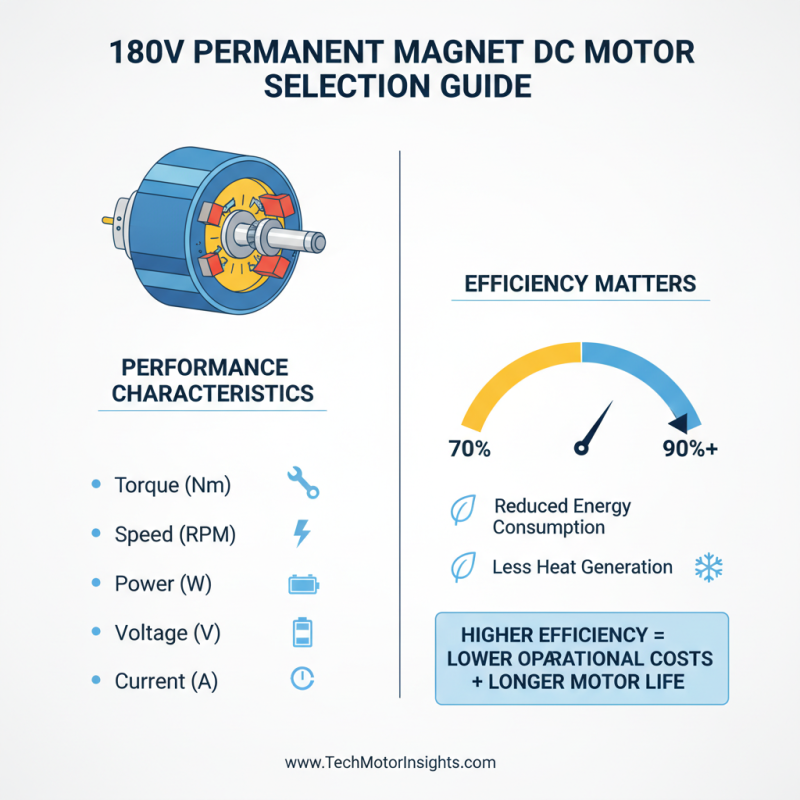

Evaluating Motor Performance Characteristics and Efficiency

When selecting a 180V permanent magnet DC motor for your project, evaluating performance characteristics and efficiency is crucial. Efficiency ratings vary significantly among motors, often ranging from 70% to 90%. Higher efficiency means reduced energy consumption and heat generation. This can lead to longer operational life and lower operational costs over time.

Consider the torque characteristics. Check the stall torque, operational torque, and the motor's ability to handle varying loads. A motor with higher peak torque is beneficial for applications with sudden load changes. However, be cautious; a motor that is too powerful may lead to faster wear, requiring more frequent maintenance and replacements.

Tips: Always examine thermal management options. If the motor runs too hot, it can compromise efficiency and lifespan. Allow for proper ventilation. Additionally, ensure your motor controller can handle the demands of the selected motor. Compatibility is key to maximizing performance.

Understanding the trade-offs is essential. A motor with high efficiency might come at a higher upfront cost. Evaluate your budget alongside your project’s performance needs. Sometimes, a less efficient motor can be more appropriate, especially for short-term projects. Balancing cost and efficiency requires careful consideration and sometimes, reflection on past experiences.

Installation and Maintenance Tips for 180V DC Motors

When installing a 180V DC motor, careful positioning is key. The motor should be mounted on a sturdy frame to minimize vibrations. Vibration can lead to mechanical wear and reduced efficiency. Use proper mounting hardware to secure the motor in place. Ensure there’s enough space for wiring and maintenance access.

Tips for installation include checking alignment. A misaligned motor shaft can cause uneven wear. Regularly inspect the motor for dust and debris accumulation. Dust can hinder airflow and cause overheating. Establish a routine maintenance schedule to clean and lubricate components. This will prolong the life of your motor.

For electrical connections, use suitable gauge wires. Poor connections can lead to overheating and failure. Always double-check voltage ratings before powering the motor. If issues arise, consult the installation manual. Understanding your motor's design can help troubleshoot effectively. Keep records of maintenance activities to spot trends. Regular maintenance can prevent serious problems down the road.

Performance Comparison of 180V Permanent Magnet DC Motors

This bar chart illustrates the performance comparison of three different models of 180V permanent magnet DC motors based on various parameters such as torque, speed, efficiency, and weight. This data can help in making informed decisions for your projects.

Related Posts

-

What is a Permanent Magnet DC Motor 90V and How Does it Work

-

Exploring the Efficiency and Applications of Permanent Magnet DC Motors at 90V

-

Top 10 Benefits of Using a 90V Permanent Magnet DC Motor for Your Projects

-

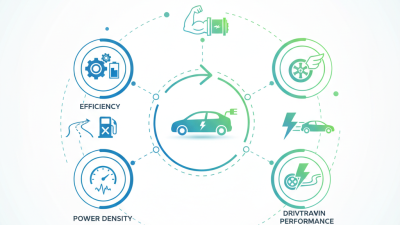

Why is PMSM Motor the Best Choice for Electric Vehicles Performance

-

2025 Guide: How to Choose the Right PM Stepper Motor for Your Project

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency