2026 How to Choose the Right IPM SYNRM Motor for Your Applications?

Selecting the right IPM SYNRM motor for your applications can significantly impact performance and efficiency. According to Dr. Emily Zhao, a leading expert in electric motor technology, "The choice of a motor should align with the specific demands of your application." This reflects the need for careful consideration.

When delving into the world of IPM SYNRM motors, understanding specifications is essential. These motors offer advantages like high efficiency and compact design. Yet, they may not suit every scenario. Each application poses unique challenges and requirements. Evaluating torque, speed, and environmental factors is crucial.

In practice, the variety of IPM SYNRM motors can be overwhelming. Choosing poorly might lead to inefficiencies or increased costs. Balancing technical details and your project's goals demands attention. Reflecting on expert advice and real-world applications helps in making an informed choice. Every decision should consider the specific needs of your application.

How to Understand the Basics of IPM SYNRM Motors in 2026

Understanding the basics of IPM SYNRM motors can empower your decision-making. These motors are vital across many applications. They blend efficiency and performance in a compact design.

An IPM SYNRM motor uses interior permanent magnets. This design minimizes energy loss. Many users overlook torque ripple. However, it plays a crucial role in performance. Failing to consider it can lead to efficiency issues in specific tasks.

Another aspect is thermal management. Heat dissipation is essential for motor reliability. Systems often need external cooling. You might think more power equals better performance. This isn't always true. Balancing power with efficiency is a challenge. Ignoring this can lead to frequent maintenance. The right motor choice hinges on understanding these details. Examine your specific needs thoroughly.

IPM SYNRM Motor Efficiency Comparison in 2026

Assessing Power Requirements for Your Applications with IPM SYNRM Motors

When selecting an IPM SYNRM motor, understanding power requirements is crucial. Assess the specific needs of your application. Consider factors like load, speed, and environmental conditions. Each application has unique demands that affect motor performance.

Next, evaluate the torque required for your tasks. High torque may be necessary for applications like robotics. On the other hand, applications demanding high-speed operations require careful power consideration. Calculate the necessary power output to avoid performance issues.

Reflect on your application’s efficiency and reliability. An undersized motor can lead to overheating and failure. Overrated motors may waste energy. Striking the right balance is essential for optimal performance.

Weigh all options and reflect on past experiences. This will guide you in making informed choices for future projects.

Exploring Efficiency Ratings: Finding the Right IPM SYNRM Motor for You

When selecting an IPM SYNRM motor, efficiency ratings play a critical role. Efficiency ratings can drastically affect operational costs. According to the National Renewable Energy Laboratory, high-efficiency motors can consume up to 30% less energy than standard models. This reduction not only saves money but can also lower environmental impact.

However, it's vital to assess your specific application needs. Factors like load type, speed requirements, and duty cycles can influence which motor is best. A poorly matched motor can lead to inefficiencies and increased wear. For example, operating a motor at low loads can decrease its efficiency to below optimal levels, potentially wasting energy.

It's important to reflect on your choices. Many applications overlook motors' efficiency when prioritizing other factors, like initial cost. This often results in higher costs over time. Consider the total cost of ownership rather than just the upfront price. Selecting the right IPM SYNRM motor requires careful thought and analysis of efficiency ratings alongside application demands.

Analyzing Torque and Speed Characteristics of IPM SYNRM Motors

When selecting an IPM SYNRM motor, torque and speed characteristics are crucial. These motors excel in various applications due to their efficiency and performance. According to recent market reports, the typical torque density for these motors ranges from 2.0 to 4.0 Nm/kg. This high torque density makes them suitable for compact designs where space is limited.

Speed performance is another critical factor. Many IPM SYNRM motors operate effectively at speeds up to 6,000 RPM. This is significant in applications like robotics and electric vehicles. However, it’s essential to analyze how the torque varies with speed. A drop in torque at higher speeds can limit performance and application suitability.

The relationship between speed and torque also presents challenges. Miscalculating this can lead to suboptimal motor selection. Efficiency losses at high RPMs can reach up to 20%. Understanding these characteristics helps highlight the importance of matching motors to specific applications. It is not only about raw numbers. The context of use matters greatly.

2026 How to Choose the Right IPM SYNRM Motor for Your Applications? - Analyzing Torque and Speed Characteristics of IPM SYNRM Motors

| Motor Model | Peak Torque (Nm) | Rated Speed (RPM) | Efficiency (%) | Power (kW) |

|---|---|---|---|---|

| Model A | 15 | 3000 | 90 | 5.5 |

| Model B | 20 | 2500 | 92 | 7.5 |

| Model C | 25 | 2000 | 91 | 10 |

| Model D | 30 | 1800 | 89 | 12 |

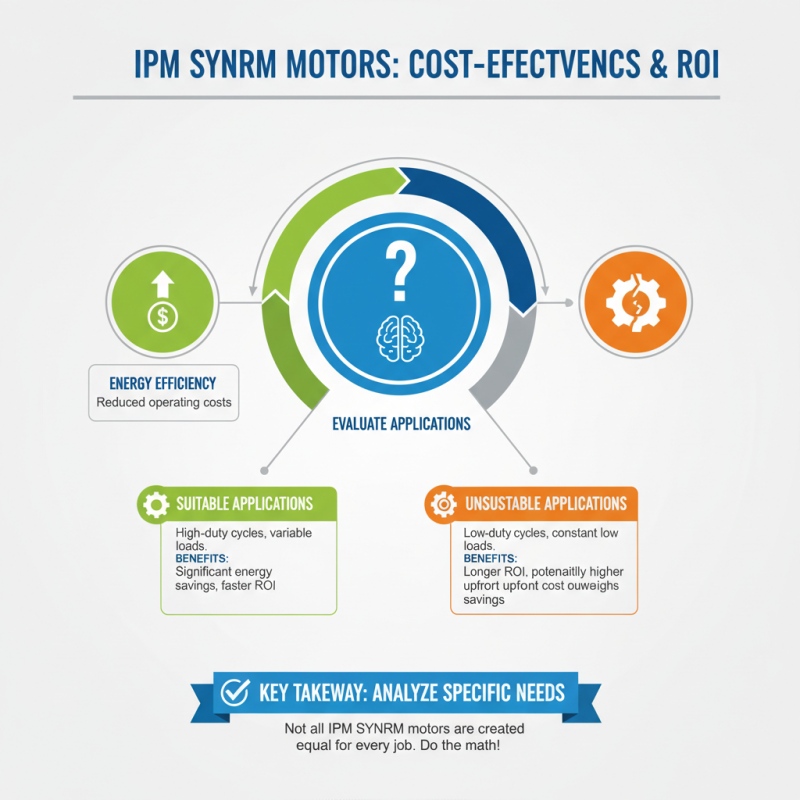

Evaluating Cost-Effectiveness and ROI for IPM SYNRM Motor Choices

When considering IPM SYNRM motors for various applications, evaluating cost-effectiveness and return on investment (ROI) is essential. These motors offer energy efficiency, but not all options are suitable for every application. It's vital to analyze specific needs before making a decision.

Tips: Focus on your operational goals. Identify how often the motor will be used. This will directly influence energy savings over time. Some motors may have a higher upfront cost. However, they can lead to long-term savings in energy bills.

Another point to consider is maintenance costs. Reliable motors may reduce downtime. A motor that requires frequent repairs can drain your budget. Assessing the total cost of ownership is crucial. Take time to compare different motor specifications and their projected lifespan.

Tips: Don’t overlook performance metrics. Consider torque and speed requirements for your setup. This directly impacts efficiency and productivity. Sometimes a less expensive option may underperform, leading to hidden costs. Balancing initial investment and operational efficiency is key for any successful application.

Related Posts

-

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

-

Top 10 Benefits of Using Permanent Magnet Motors in Modern Applications

-

Top 10 Benefits of Using 3 Phase Permanent Magnet Motor in Industry?

-

How to Choose the Right PM Motor for Your Application?

-

How to Choose the Right PM Motor for Your Project?