How to Choose the Right Magnets for Motors in Your Projects?

Choosing the right magnets for motors is crucial in engineering projects. According to John Smith, a renowned expert in magnet technology, "Selecting the perfect magnets for motors can elevate your design's efficiency." This statement emphasizes the significant role magnets play in motor performance.

Magnets for motors come in various shapes and strengths. Every application can have unique requirements. Understanding these needs is essential. For instance, neodymium magnets offer high performance in compact spaces. However, they can be more expensive. On the other hand, ferrite magnets are affordable but may not provide the same power.

Experimenting with different magnets for motors can lead to unexpected challenges. It's important to analyze the specific requirements of each project. A major mistake can arise from overestimating magnet strength. This often results in issues like overheating or motor failure. Careful consideration of all factors is vital for success.

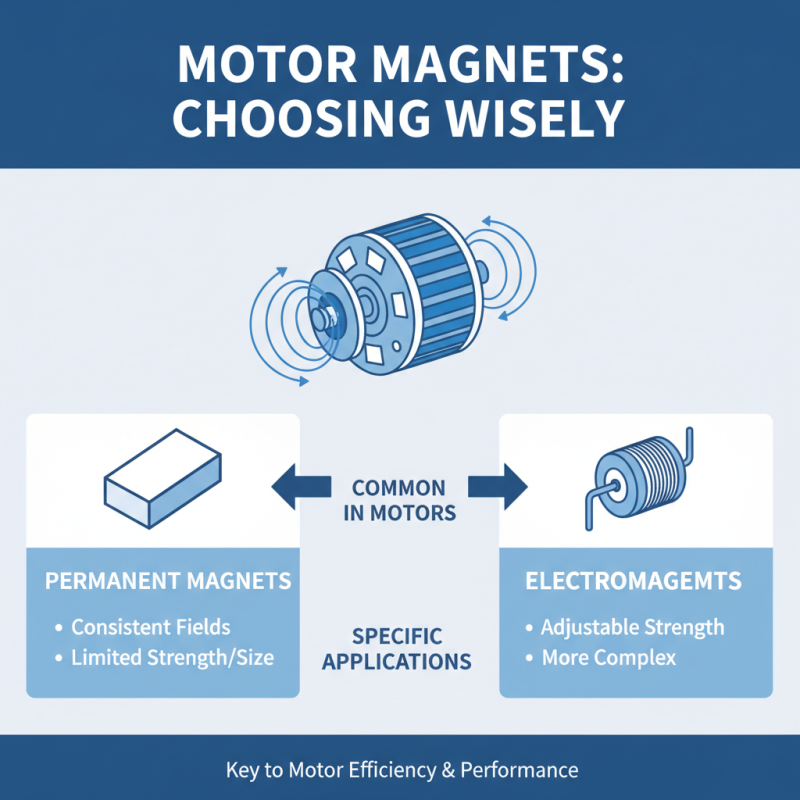

Understanding Different Types of Magnets for Motor Applications

When working on motor projects, choosing the right magnets is crucial. There are several types of magnets, each with unique properties. Permanent magnets are commonly used in motors. They provide consistent magnetic fields. However, they can be limited in strength and size.

Electromagnets offer more versatility. By adjusting the current, you can change their strength. This feature makes them useful for many applications. However, they require power, which may complicate your design. On the other hand, hybrid magnets combine both types, providing a balance of performance.

Considerations like size, weight, and cost play a significant role. Sometimes, the best choice isn’t the most powerful magnet. In some cases, a smaller magnet may suffice, saving space. Think about your project’s specific needs. Testing different magnets can help, but be cautious. Too many options can lead to confusion.

Evaluating Magnetic Properties: Strength, Size, and Shape Considerations

When choosing magnets for motors, understanding their magnetic properties is essential. The strength of a magnet is critical for the performance of your motor. High-strength magnets can provide more torque. However, they also can be more expensive and heavier. Finding a balance is important. Don’t always go for the strongest magnet; sometimes less is more.

The size and shape of the magnet also play a significant role. A larger magnet might have a stronger pull, but it could also add unwanted bulk. Consider the design of your project. Are you trying to keep it compact or do you need power? Magnetic shape can impact the field distribution. A flat magnet may fit better in tight spaces than a bulky block. Sometimes, trial and error is needed to find the right fit. Testing different options before finalizing can help ensure you are on the right track.

Lastly, remember that environmental factors also influence magnet performance. Temperature can affect magnet strength. Ensure your magnets can withstand the operational environment of your project. You may need magnets that work well in high temperatures or humid conditions. Reflect on these aspects carefully to avoid pitfalls in your project setup.

Magnetic Properties Evaluation for Motors

Assessing Temperature and Environmental Factors in Magnet Selection

When selecting magnets for motors, temperature and environmental factors play a crucial role. Different magnets react brightly or poorly to changing conditions. For instance, high temperatures can lead to a significant reduction in magnetic strength. Consider the type of insulation in your motor. It affects how well the magnets can handle heat.

Beyond heat, moisture and humidity also impact magnet performance. Some materials corrode more easily than others. This could lead to failure in critical applications. If you overlook these factors, your project may suffer later. Assess your environment carefully.

Evaluating the surroundings helps you choose the right magnets. Think about temperature ranges. What if you design something for outdoor use? Consider the rain, snow, and sunlight. Such details matter greatly. Each element affects magnet performance. Asking the right questions can guide your selection process. Don’t rush through this stage to avoid future problems.

How to Choose the Right Magnets for Motors in Your Projects? - Assessing Temperature and Environmental Factors in Magnet Selection

| Magnet Type | Max Operating Temperature (°C) | Corrosion Resistance | Typical Applications | Environmental Factors |

|---|---|---|---|---|

| Neodymium (NdFeB) | 80 | Moderate (coated) | Electric motors, sensors | Humidity, dust |

| Samarium Cobalt (SmCo) | 300 | High | Aerospace, military | Extreme temperatures |

| Ceramic (Ferrite) | 250 | Moderate | Household appliances, toys | Low costs, general use |

| Alnico | 550 | Good | Microphones, guitar pickups | Stable at high temps |

Comparing Cost and Availability of Various Magnet Materials

When selecting magnets for motors, cost and availability are critical factors. Different materials have varying prices and accessibility. For instance, neodymium magnets are powerful but can be more expensive due to rare earth elements. According to industry reports, neodymium magnets can cost up to three times more than ferrite magnets. Ferrite, while less powerful, offers a cost-effective alternative.

Tip: Always consider your project budget. If you can compromise on strength, ferrite is often the best choice. It’s affordable and widely available.

Another factor to consider is the supply chain. Some materials, like aluminum-nickel-cobalt magnets, have fluctuating market prices depending on mining conditions. This can affect project costs unexpectedly. Keep an eye on market trends.

Tip: Regularly check material suppliers for updates. A simple shift in availability may change your project timeline. Be prepared for possible adjustments.

Ultimately, the right magnet choice balances performance, cost, and availability. Understanding these variables will help you navigate the market effectively.

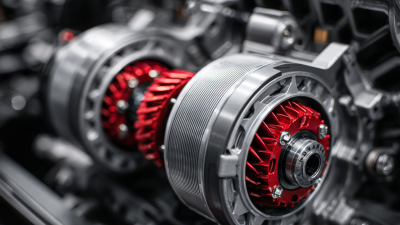

Testing and Prototyping: Ensuring Compatibility with Motor Design

Selecting the right magnets for motors is crucial for project success. Testing and prototyping are essential steps to ensure compatibility with motor design. Each motor type demands specific magnetic properties. Weak matches can lead to inefficiencies or even operational failure. Industry studies show that a 10% mismatch can decrease performance by over 25%.

When prototyping, analyze the torque and rotational speed requirements. Different applications need different magnet strengths. For example, high-speed motors often require neodymium magnets due to their strong magnetic fields, while other applications may benefit from ferrite magnets.

Tip: Always test with the actual motor configuration. Small changes in the setup can yield vastly different results. A professional report indicates that 30% of prototype failures stem from incorrect magnetic material selection. Prototyping helps visualize how magnets interact with motor designs, revealing deeper insights.

Keep in mind that budget constraints can push for less optimal choices. While cost is important, poor performance may lead to higher costs in the long run. Balancing performance and budget is critical. This often leads to hard decisions that demand careful thought and evaluation.

Related Posts

-

Revolutionizing Robotics: The Essential Role of DC Motor Magnets in Modern Technology

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

-

10 Essential Tips for Choosing the Right Magnets for Motors

-

Top 10 Best Magnets for Motors to Boost Performance and Efficiency

-

Why is PMSM Motor the Best Choice for Electric Vehicles Performance

-

How to Choose the Right IPM SynRM Motor for Your Next Project