How to Choose the Right PM Motor for Your Application?

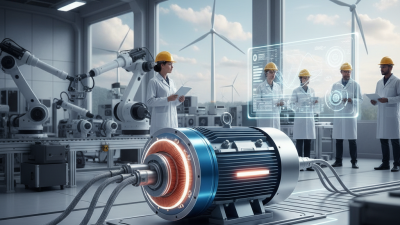

Choosing the right PM motor for your application is crucial. The market for permanent magnet motors is expected to grow significantly. According to a recent report, this sector could reach $27 billion by 2027. Factors such as efficiency and performance heavily influence this growth.

When selecting a PM motor, it’s essential to consider the application requirements. Look at the torque, speed, and power rating. Many industries rely on these motors. For instance, the automotive sector increasingly adopts PM motors for electric vehicles. These motors enhance vehicle efficiency.

However, not all PM motors are suitable for every application. Miscalculating needs can lead to inefficiencies. Take time to analyze specific demands. Understanding your requirements can prevent costly mistakes. The choice can often feel overwhelming. An informed decision requires clarity about both the motor and the application.

Understanding the Operational Requirements of Your Application

When selecting a PM motor, understanding the operational requirements of your application is crucial. Factors like torque, speed, and efficiency directly impact performance. According to a recent industry report, 45% of motor failures are linked to improper torque selection. This underscores the need for careful analysis of your application's demands.

Evaluate the load characteristics and motion profile. For instance, a motor that can handle steady loads may not perform well in start-stop scenarios. More granular data suggests that 30% of applications experience inefficiencies due to mismatched operational profiles. Adapting your motor choice to suit dynamic conditions can enhance performance significantly.

Additionally, consider environmental factors. Heat, humidity, and dust can affect motor longevity. A study shows that 25% of motors fail prematurely due to unsuitable environmental conditions. This information prompts a deeper reflection on how robust components are selected. Ignoring these factors could lead to underperformance or, worse, operational shutdowns.

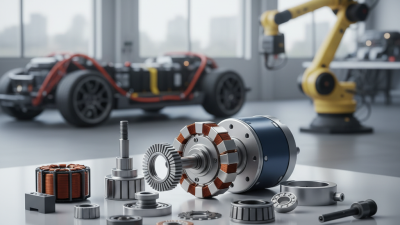

Evaluating the Key Specifications of PM Motors

When selecting a permanent magnet (PM) motor, evaluating key specifications is crucial. Start with the motor's torque rating. This metric defines its performance under load. According to the International Electrotechnical Commission (IEC), motors with a higher torque can handle greater loads, typically showing a more efficient output. However, excessively high torque can lead to overheating and reduced lifespan. You need to ensure balance in performance.

Another vital specification is efficiency. Many PM motors boast efficiencies above 90%. But, factors like speed and load affect this efficiency. A report from the Electric Power Research Institute (EPRI) highlights that even minor mismatches between motor and application can decrease performance significantly. This mismatch often results in wasted energy, an important reflection point during selection.

Noise levels also matter. PM motors generally run quieter than other types. Yet, not all applications suit this silent operation. Some sectors require specific noise thresholds. It's important to assess how noise impacts your work environment. Overall, comparing these specifications helps avoid oversights that lead to operational challenges. Selection is a careful balance of many factors.

Comparing the Efficiency Ratings of Different PM Motors

When selecting a permanent magnet (PM) motor, efficiency plays a crucial role. Different PM motors exhibit varying efficiency ratings that can significantly affect performance. Efficiency ratings generally indicate how well a motor converts electrical energy into mechanical energy. A high-efficiency motor may seem ideal, but sometimes the most efficient option does not fit the application perfectly.

For example, a motor with a slightly lower efficiency rating might operate more effectively for a specific load. It may also provide better torque characteristics. Evaluating the operational context is essential. Consider factors like speed range, load demands, and environmental conditions. It can be easy to overlook these specifics while fixating on efficiency numbers alone.

Moreover, continuous improvements in motor design impact efficiency ratings. However, not all manufacturers publish reliable data. This inconsistency can mislead buyers. It’s beneficial to seek out detailed specifications and real-world performance reviews. Reflecting on the importance of application rather than just statistics can lead to more informed decisions. Balancing efficiency with practical needs is key to choosing the right PM motor.

Efficiency Comparison of Different PM Motors

Assessing the Cost-Effectiveness of PM Motors in Long-Term Use

Choosing the right permanent magnet (PM) motor is crucial for any application. When assessing cost-effectiveness, it’s essential to consider long-term use. PM motors have high efficiency, but initial costs can be significant. Paying attention to longevity can outweigh upfront expenditures.

Cost-effectiveness involves maintenance and energy consumption. PM motors often require lower maintenance due to fewer moving parts. However, over time, demagnetization risks can arise, which might lead to unexpected expenses. Consider how often you will use the motor. A motor running continuously may justify a higher initial cost.

Also, evaluate your energy needs. PM motors generally consume less energy than traditional motors. But, fluctuations in power supply can impact overall efficiency. Think about your application’s specific load requirements. Will the motor operate under constant or variable load? These factors can help pinpoint the right motor and ensure a better return on investment. Balancing cost, efficiency, and operational demands is vital for making an informed decision.

How to Choose the Right PM Motor for Your Application? - Assessing the Cost-Effectiveness of PM Motors in Long-Term Use

| Motor Type | Rated Power (kW) | Efficiency (%) | Initial Cost ($) | Annual Operating Cost ($) | Total Cost Over 10 Years ($) |

|---|---|---|---|---|---|

| Type A | 5 | 90 | 2,000 | 300 | 5,000 |

| Type B | 7.5 | 92 | 2,500 | 350 | 5,500 |

| Type C | 10 | 94 | 3,000 | 400 | 6,000 |

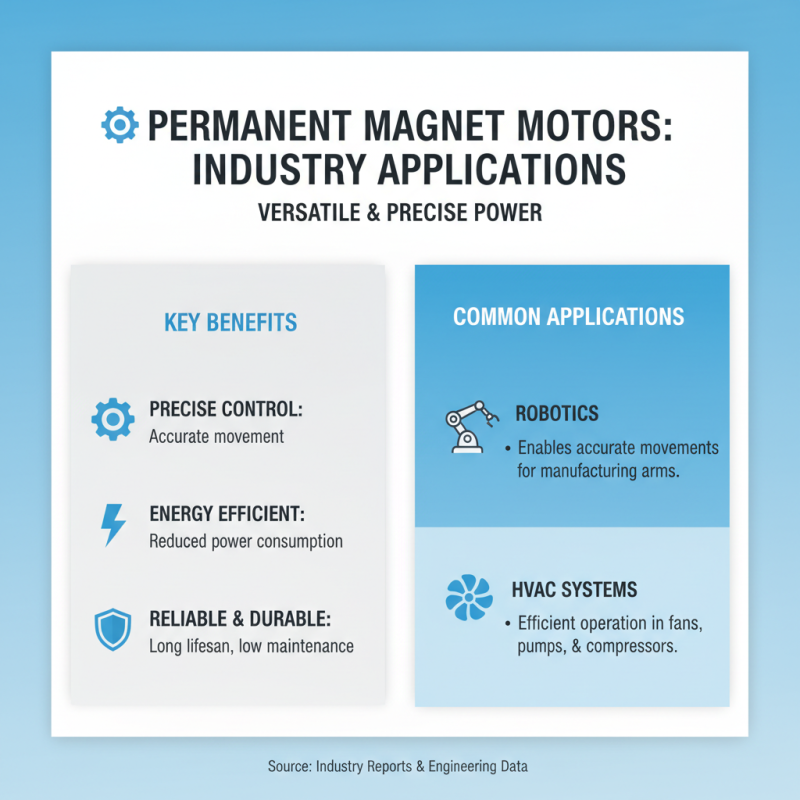

Identifying the Common Applications of PM Motors in Industry

Permanent magnet (PM) motors are widely used across various industries. Their applications span from robotics to HVAC systems. For example, in robotics, these motors provide precise control. They enable accurate movements for robotic arms in manufacturing.

In the HVAC industry, PM motors drive fans and compressors. They improve energy efficiency significantly compared to traditional motors. However, choosing the right motor can be challenging. Not all applications require the same specifications. Knowing the environment, load, and required performance is crucial.

In packaging machines, PM motors offer improved speed control. This helps in aligning products accurately on the assembly line. Yet, sometimes the integration process can lead to unexpected issues. Ensuring compatibility with existing systems is vital. Using PM motors appropriately can enhance productivity. However, careful planning is essential to avoid inefficiencies.

Related Posts

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

-

Top 10 Benefits of Using Permanent Magnet Motors in Modern Applications

-

Top 10 Benefits of Using 3 Phase Permanent Magnet Motor in Industry?

-

10 Tips for Understanding Direct Current Permanent Magnet Motors

-

10 Essential Tips for Using a Neodymium Magnet Generator Effectively

-

Top 10 Benefits of Using a Permanent Magnet DC Motor 90V for Your Projects