How to Choose the Right PM Motor for Your Project?

Choosing the right PM motor is critical for project success. According to a 2023 industry report by TechInsights, the demand for PM motors is projected to grow by 7% annually. This growth reflects the increasing focus on energy efficiency and sustainable solutions.

Experts emphasize the importance of making informed choices. Dr. Emily Johnson, a leading figure in motor technology, states, “Selecting the appropriate PM motor can enhance performance and reduce costs.” This underscores the need for thorough analysis.

In selecting a PM motor, consider various factors. Different applications require different specifications. The intricacies of torque, speed, and efficiency ratings may lead to confusion. Striking a balance can be challenging. An informed selection process can be the difference between project success and failure.

Understanding the Basics of PM Motors and Their Applications

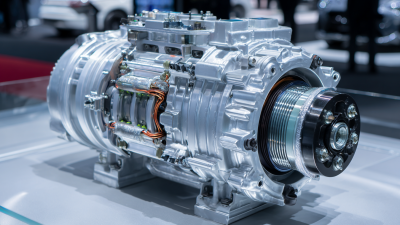

Permanent magnet (PM) motors are increasingly popular in various applications. They are efficient and compact. These motors convert electrical energy into mechanical energy with minimal losses. Understanding their design and function is essential before making a selection.

PM motors come in different types, including brushed and brushless. Brushless motors often excel in efficiency and require less maintenance. Consider the operating environment when choosing a motor. For instance, high temperatures can impact performance. An expert might suggest looking at torque and speed ratings too.

Applications range from robotics to HVAC systems. Each project requires specific features. It's not uncommon to underestimate the load requirements. Testing the motor in real-life scenarios is vital. The right motor can enhance efficiency, but the wrong choice may lead to issues. Always weigh options carefully and reflect on performance after implementation.

Identifying Project Requirements and Specifications for PM Motors

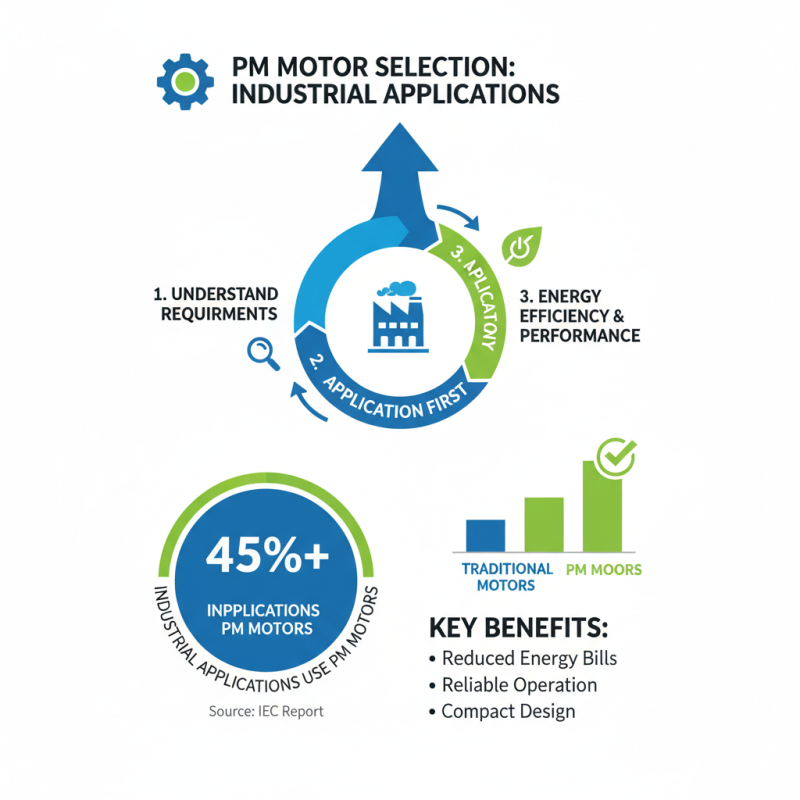

When selecting a permanent magnet (PM) motor, understanding your project's requirements is essential. Consider the application first. For example, a report from the International Electromechanical Commission stated that over 45% of industrial applications use PM motors. This highlights their significance in energy efficiency and performance.

Power and torque specifications are crucial factors. Determine the load the motor must handle. In many cases, torque should match the peak demand of the application. Oversizing a motor can lead to inefficiencies. Conversely, undersizing can result in motor failure. Accurate load analysis will help ensure the motor fits seamlessly into your system.

Additionally, consider environmental conditions. PM motors may operate in harsh conditions, impacting their sustainability. A study by the Electric Power Research Institute found that around 30% of motor failures are due to environmental factors. Dust, moisture, and temperature variations can all play a role. As a project manager, reflecting on these aspects is essential. Plan for contingencies and possible motor adjustments in your project timeline.

Evaluating PM Motor Performance Characteristics and Efficiency

When selecting a permanent magnet (PM) motor, performance characteristics matter greatly. Look into torque, speed, and efficiency. Torque is a key factor for applications needing consistent power. Review the motor's rated torque and its performance curve. A motor might have high initial torque but quickly lose efficiency.

Efficiency is often represented as a percentage. Higher efficiency means reduced energy consumption. However, some motors may achieve high efficiency at specific loads while performing poorly at lower ones. This can lead to misleading expectations. Always ask about efficiency at different operation points to gain a clearer picture.

Tips: Consider ambient conditions when measuring efficiency. Heat can impact motor performance. If a motor operates in a hot environment, you might see reduced output. It’s vital to balance these factors during your evaluation. Ask manufacturers directly for their efficiency datasheets.

Another aspect is load tuning. Some PM motors require tuning to function optimally. If you plug in a motor without adjustments, you may encounter inefficiencies. Think about the application—it may not need the highest performance but rather reliability over time.

How to Choose the Right PM Motor for Your Project? - Evaluating PM Motor Performance Characteristics and Efficiency

| Motor Type | Rated Power (kW) | Voltage (V) | Efficiency (%) | Torque (Nm) | Speed (RPM) |

|---|---|---|---|---|---|

| Brushless DC Motor | 3.0 | 48 | 90 | 10 | 3000 |

| Permanent Magnet Synchronous Motor | 5.5 | 380 | 92 | 28 | 1500 |

| Step Motor | 1.2 | 24 | 85 | 6 | 2000 |

| Switched Reluctance Motor | 4.0 | 220 | 88 | 15 | 4000 |

Comparing Different Types of PM Motors for Specific Use Cases

When choosing a PM motor, it's crucial to consider the specific application. Different types of PM motors have unique characteristics, making them suited for various scenarios. For instance, brushless PM motors excel in applications requiring high efficiency and reliability. They are often used in robotics and HVAC systems. These motors provide excellent torque and speed control, which is vital in precision tasks.

However, brushed PM motors may be a better fit for simpler tasks. These motors are easier to control and often cheaper. They work well in small appliances, like toy cars and basic home devices. The drawback is the maintenance required due to brush wear over time.

**Tip:** Always assess your project's power requirements. Measure efficiency, torque, and speed before making a choice.

Another important aspect is the environment where the motor will be used. High humidity or extreme temperatures can affect performance. Consider sealed motors for harsher conditions. Not every motor will thrive in challenging environments, so do your research.

**Tip:** Look into motor ratings carefully. They can provide insight into suitability for your application. Don't hesitate to consult experts when in doubt.

Comparing Different Types of PM Motors for Specific Use Cases

This chart compares the efficiency, cost, and torque of various types of Permanent Magnet (PM) motors commonly used in different applications.

Budgeting and Sourcing: Finding the Right PM Motor for Your Needs

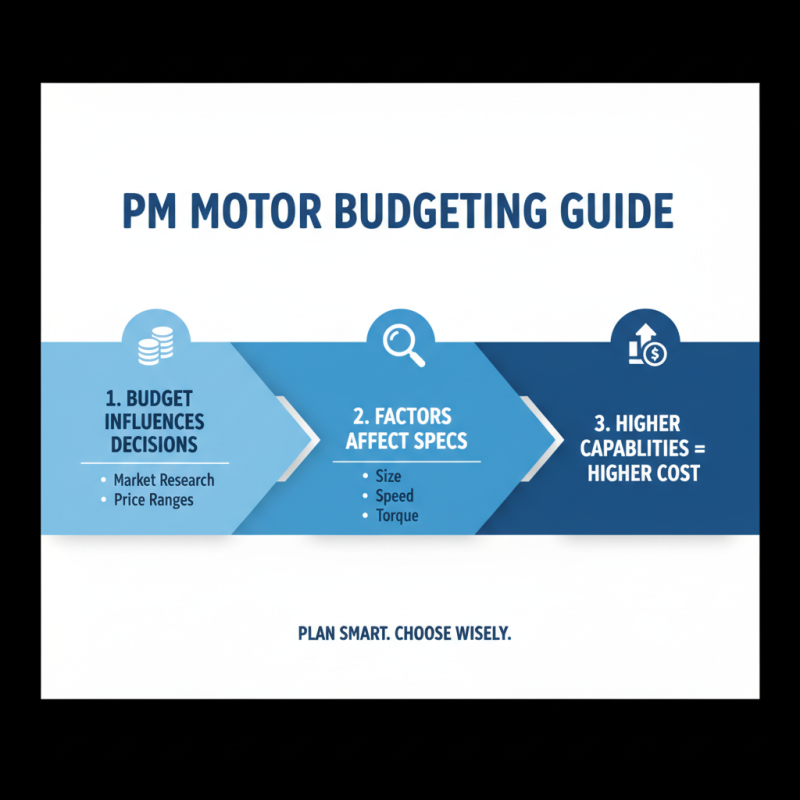

Budgeting for a PM motor can be challenging. Your budget influences many decisions. It’s crucial to conduct market research. This helps you understand price ranges. Prices can vary based on specifications. Consider size, speed, and torque. Higher capabilities often mean higher costs.

Sourcing the right motor requires careful planning. Look for local suppliers to reduce shipping fees. Online resources provide many options. However, ensure quality by checking reviews. Not all sellers are reliable. Reaching out to manufacturers directly can help. They may offer better prices or customization options.

You might feel overwhelmed by choices. Narrow down your requirements first. Consider the application and its demands. This can simplify the process. Remember to account for additional costs such as installation. Overlooked expenses can strain budgets unexpectedly. Regularly evaluate your choices to make informed decisions. Acting too quickly might lead to regrets later.

Related Posts

-

Top 10 Benefits of Using 3 Phase Permanent Magnet Motor in Industry?

-

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

-

How to Choose the Right PM Motor for Your Application?

-

Unlocking Efficiency: How IPM SynRM Motors Revolutionize Modern Industrial Applications

-

How to Choose the Right IPM SynRM Motor for Your Next Project

-

2025 Guide: How to Choose the Right PM Stepper Motor for Your Project