Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

The rise of renewable energy systems has necessitated a shift towards technologies that enhance efficiency and sustainability. One such technology, the direct current permanent magnet motor (DCPMM), is revolutionizing the landscape of energy conversion and consumption. According to a report by the International Energy Agency (IEA), the integration of permanent magnet motors in renewable applications can improve overall system efficiency by up to 30%, significantly reducing operational costs and energy waste. Additionally, as the global push for carbon neutrality intensifies, the demand for efficient electric motors, particularly DCPMMs, is projected to grow exponentially, with an expected CAGR of 7.5% from 2021 to 2026, as highlighted by a recent market research study. This shift towards direct current permanent magnet motors is not just a technological upgrade but a pivotal step towards a more sustainable future, aligning with the global goals of reducing greenhouse gas emissions and enhancing energy efficiency.

The Evolution of Direct Current Permanent Magnet Motors in Energy Systems

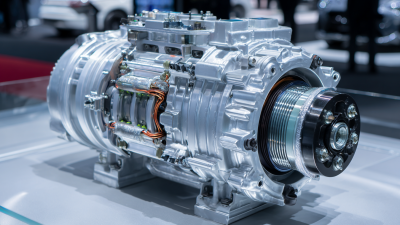

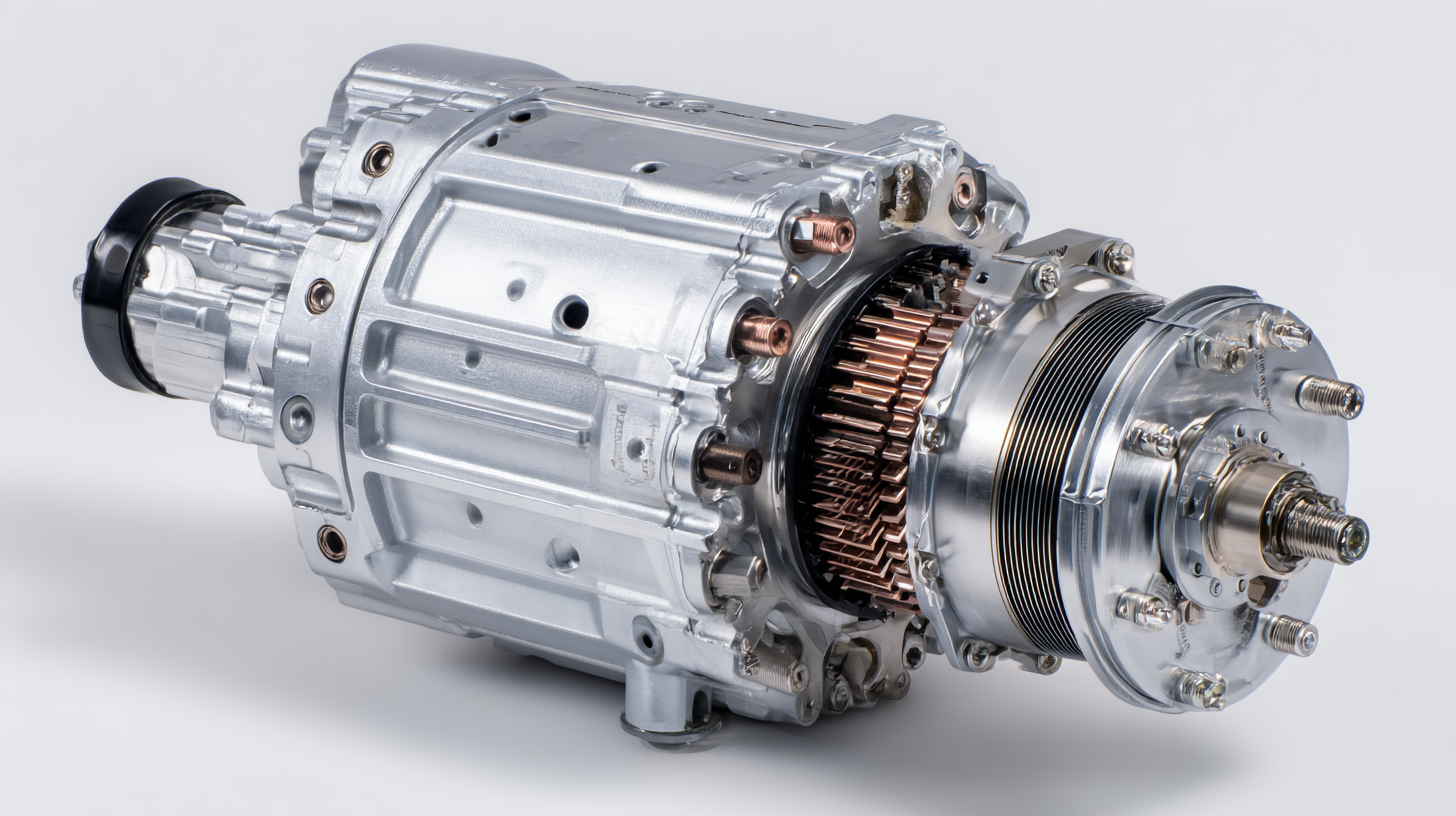

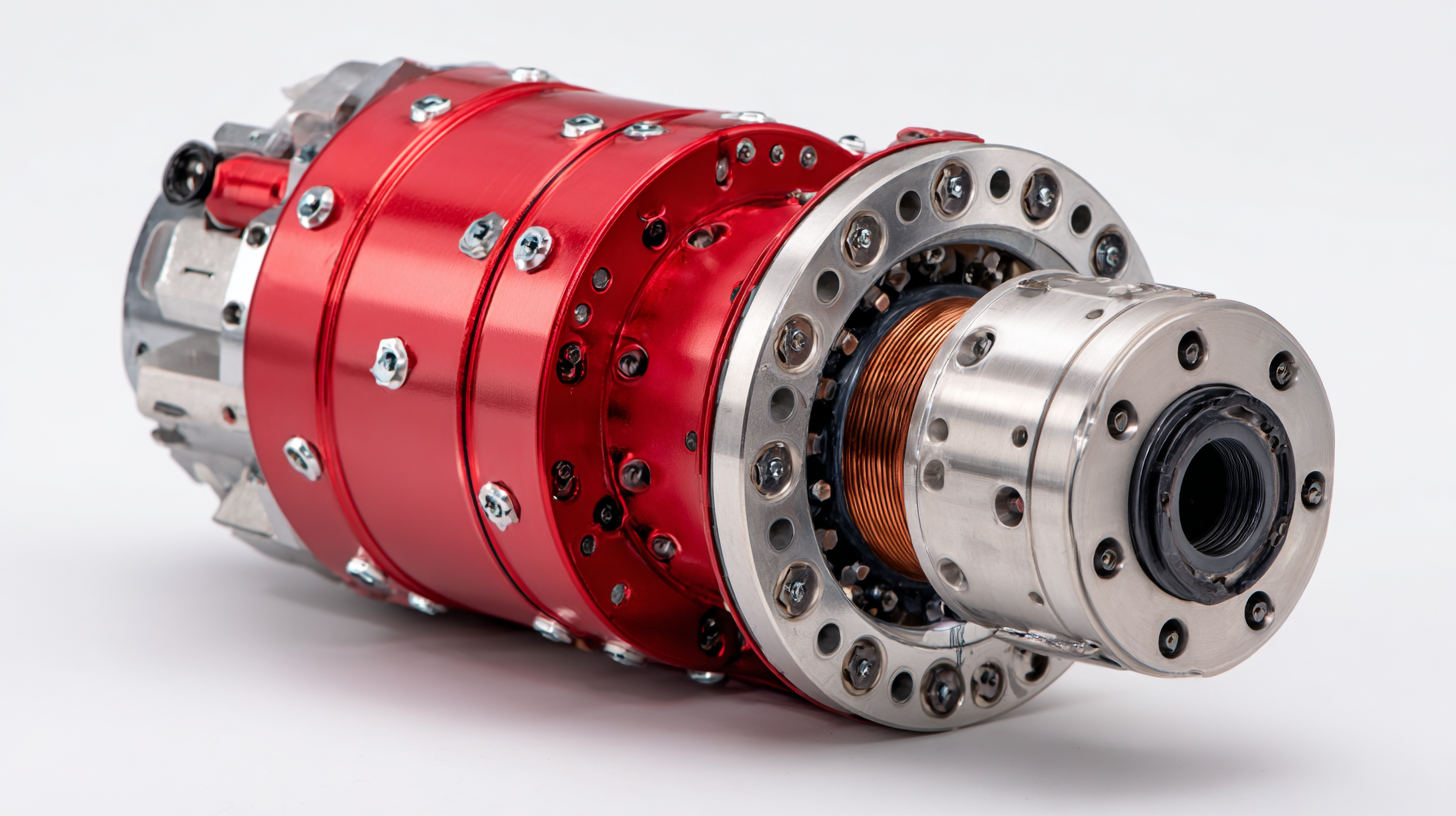

The evolution of Direct Current Permanent Magnet (DCPM) motors has marked a significant milestone in the advancement of energy systems, particularly in the realm of renewable energy. Initially developed for specific industrial applications, these motors have undergone substantial transformations over the decades. Modern advances in materials science and magnetic design have led to motors that are not only more efficient but also lighter and more compact. The integration of sophisticated control systems further enhances their performance, allowing for precise speed and torque management, which is crucial in variable renewable energy applications.

As the global focus shifts toward sustainable energy solutions, DCPM motors are becoming increasingly vital. Their high efficiency and reliability make them ideal candidates for applications such as wind turbine drives, solar tracking systems, and electric vehicles. The trend towards hybrid and fully electric systems has propelled research and development, pushing the boundaries of DCPM technology. This, in turn, supports the transition to greener energy systems, enabling them to meet the rising demand for cleaner and more efficient power sources.

Key Advantages of Direct Current Motors in Renewable Applications

Direct Current (DC) Permanent Magnet Motors are at the forefront of enhancing efficiency in modern renewable energy systems. Their ability to convert electrical energy into mechanical energy with minimal losses makes them ideal for applications in wind turbines, solar panel tracking systems, and energy storage solutions. A report by MarketsandMarkets indicates that the global market for DC motors is expected to reach $6.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.6% from 2021. This growth highlights the increasing demand for more efficient motor solutions in renewable sectors.

Direct Current (DC) Permanent Magnet Motors are at the forefront of enhancing efficiency in modern renewable energy systems. Their ability to convert electrical energy into mechanical energy with minimal losses makes them ideal for applications in wind turbines, solar panel tracking systems, and energy storage solutions. A report by MarketsandMarkets indicates that the global market for DC motors is expected to reach $6.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.6% from 2021. This growth highlights the increasing demand for more efficient motor solutions in renewable sectors.

One of the significant advantages of DC motors in renewable applications is their superior torque-to-weight ratio. This allows for more compact designs and facilitates the integration into space-constrained environments. Additionally, DC motors are easier to control, which enables fine-tuning of the energy output to match varying supply conditions. A study by the International Energy Agency (IEA) found that using high-efficiency DC motors could improve overall system efficiency by up to 30%, significantly reducing operational costs and energy consumption.

Tips: When selecting a motor for renewable energy applications, consider the specific torque requirements and operational environment. It’s also essential to assess the compatibility of the motor with existing control systems to maximize efficiency. Look for motors with integrated sensors for real-time performance monitoring, which can provide valuable insights into operational efficiency and maintenance needs.

Integration of Direct Current Motors with Solar and Wind Energy Solutions

The integration of direct current (DC) motors with solar and wind energy solutions is shaping a new paradigm in renewable energy systems. DC permanent magnet motors are particularly well-suited for this context due to their high efficiency and adaptability, making them ideal for various applications in sustainable energy generation. As countries shift towards greener technologies, the demand for robust power solutions that can seamlessly integrate with renewable sources has intensified. The compatibility of DC motors with solar panels and wind turbines not only enhances system efficiency but also improves overall energy management.

In addition, the growing DC solar cable market is a crucial factor in supporting this transition. The market is projected to reach USD 4.7 billion by 2035, driven by the increasing adoption of solar energy systems worldwide. Innovations such as brushless submersible DC solar pumps are exemplifying this trend, as they provide sustainable irrigation solutions capable of delivering significant daily water output. As such, the synergy between direct current motors and renewable energy technologies signals a transformative shift towards more efficient, environmentally friendly energy systems.

Technological Innovations Enhancing Motor Efficiency and Performance

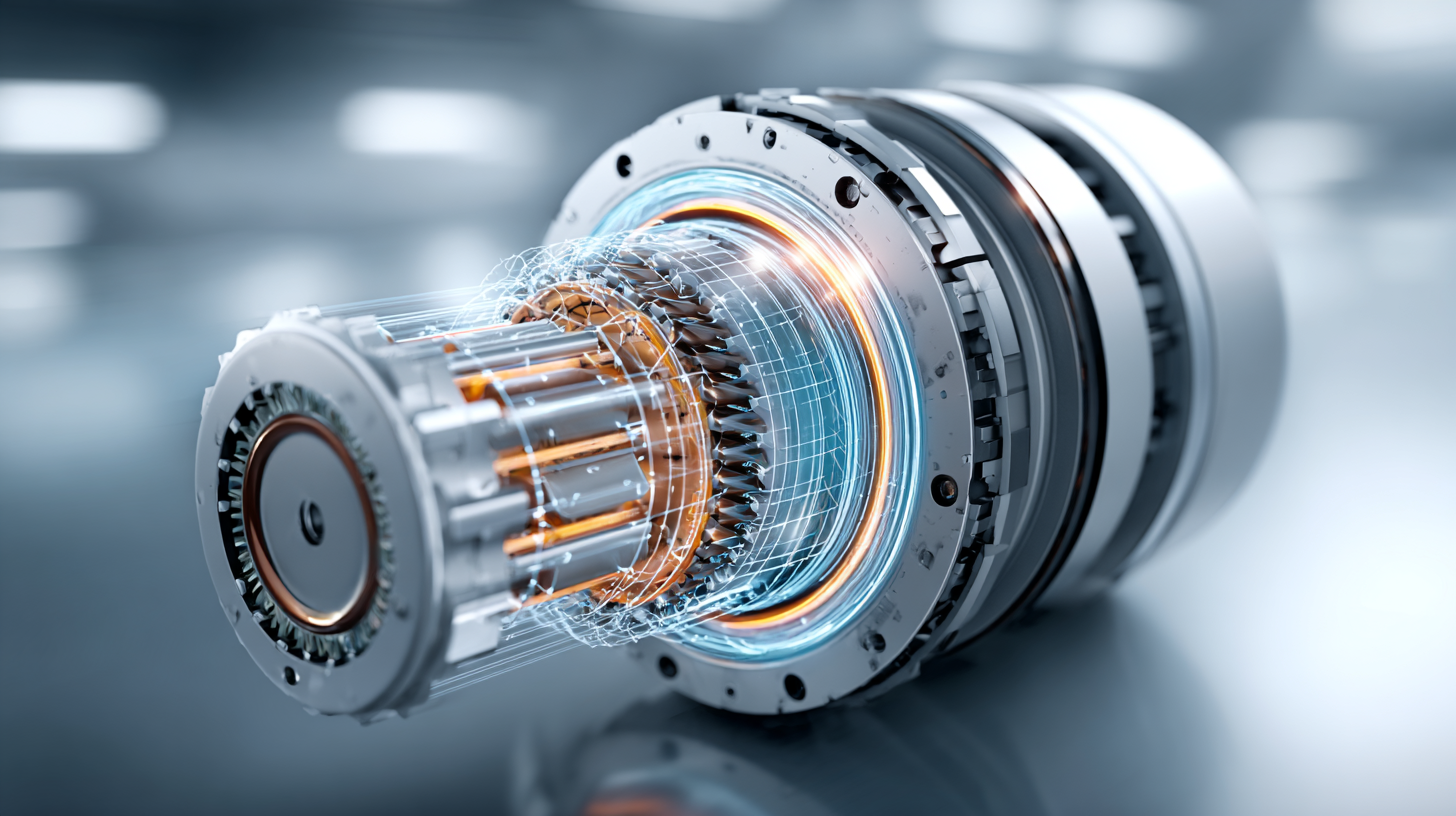

Advancements in technology have significantly enhanced the efficiency and performance of direct current permanent magnet motors (DCPMMs), positioning them as pivotal components in modern renewable energy systems. One of the key innovations lies in the development of high-energy permanent magnets that reduce energy loss during motor operation. These magnets, often made from advanced composite materials, provide a stronger magnetic field, allowing the motors to achieve higher torque and better performance while consuming less energy. This improvement translates into higher overall system efficiencies, making renewable energy solutions more viable and competitive.

Additionally, state-of-the-art control algorithms have greatly optimized the operation of DCPMMs. By utilizing sophisticated digital signal processing techniques, these algorithms enable precise control over motor speed and torque, enhancing the responsiveness and adaptability of the motors to fluctuating power requirements typical of renewable energy systems. The integration of sensorless control methods further reduces dependence on physical sensors, decreasing both mechanical complexity and potential failure points. Collectively, these technological innovations not only elevate the performance of DCPMMs but also contribute to the sustainability and reliability of renewable energy applications in an ever-evolving energy landscape.

Revolutionizing Efficiency: Direct Current Permanent Magnet Motors in Renewable Energy Systems

This chart illustrates the efficiency improvements of Direct Current Permanent Magnet Motors (DCPMMs) in modern renewable energy systems over the past years. Higher efficiency leads to enhanced performance and sustainability.

Future Perspectives on Direct Current Motors in Sustainable Energy Deployment

The integration of Direct Current (DC) Permanent Magnet Motors (PMSMs) into renewable energy systems is poised to transform the efficiency and reliability of energy deployment. According to the International Renewable Energy Agency (IRENA), global renewable energy capacity could reach 8,000 GW by 2030, with an increasing reliance on sophisticated motor systems for energy conversion and management. With their high torque density and improved efficiency, DC PMSMs are becoming integral to wind turbines and solar tracking systems, which require precise motion control and minimal energy loss, enhancing overall output.

As we look to the future, the potential for DC motors in sustainable energy deployment is augmented by advancements in materials and technology. A recent report from the U.S. Department of Energy highlights that implementing next-generation PM motors can increase system efficiency by up to 20%, significantly reducing operational costs. The ongoing trend towards electrification and automation within renewable sectors underscores the need for reliable and efficient motor systems, positioning DC PMSMs as pivotal components that will help meet ambitious global energy transition goals. This evolution not only drives technological progress but also aligns with economic objectives, facilitating the broader adoption of renewable energy solutions.