Exploring the Efficiency and Applications of Permanent Magnet DC Motors at 90V

In the realm of electrical engineering, the effectiveness and versatility of permanent magnet DC motors at 90V are increasingly being recognized. These motors, known for their high efficiency and reliability, serve a myriad of applications ranging from industrial machinery to consumer electronics. Dr. Emily Carter, a leading expert in motor technologies, states, "The use of a permanent magnet DC motor at 90V not only enhances performance but also reduces energy consumption, making it a pivotal choice for modern engineering solutions."

This statement underscores the significant advantages associated with adopting the 90V variant of permanent magnet DC motors. As industries seek to optimize their energy use and enhance operational productivity, the drive towards integrating advanced motor technologies has never been more critical. The efficiency of these motors at higher voltages leads to improved torque characteristics, thus enabling better performance in demanding environments.

Furthermore, exploring the applications of permanent magnet DC motors at 90V reveals their essential role in advancements across various sectors. As we delve deeper into the efficiency and potential industrial applications of this technology, it becomes clear that understanding the capabilities of permanent magnet DC motors at 90V is vital for engineers and decision-makers striving to push the boundaries of innovation.

Understanding the Basics of Permanent Magnet DC Motors Operating at 90V

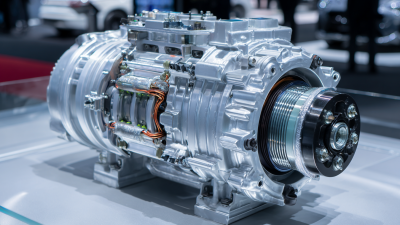

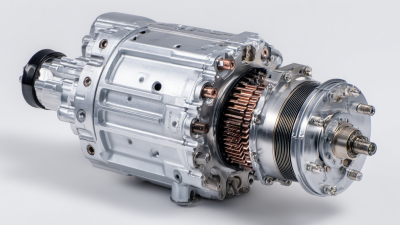

Permanent Magnet DC (PMDC) motors are widely recognized for their effectiveness in various applications due to their simplicity and high efficiency, especially at operating voltages of 90V. The fundamental principle behind these motors involves the use of permanent magnets to create a magnetic field, enabling a direct current to produce rotational movement. This design allows for higher torque output and better speed control compared to other motor types. As the demand for efficient electric motors continues to grow, understanding the technical nuances and operational efficiencies at higher voltages becomes increasingly important for both manufacturers and users.

At 90V, PMDC motors can perform optimally in automotive and industrial applications. Their compact design and reliable performance make them suitable for electric vehicles and automation systems. Furthermore, advancements in materials and technology enhance their durability and operational lifespan. As the automotive industry strives for increased safety and fuel efficiency, the characteristics of PMDC motors position them as crucial components in the shift toward electric mobility and smarter transportation solutions. The continuous evolution of these motors will likely open new avenues for innovative applications and improved energy management.

Advantages of Using 90V in Permanent Magnet DC Motors

The use of 90V in Permanent Magnet DC Motors (PMDC) offers several significant advantages that enhance their performance in various applications. One of the primary benefits is the improved efficiency achieved at this voltage level. Higher voltage systems can reduce current draw for the same power output, resulting in lower I²R losses associated with heat generation. This efficiency can lead to less energy consumption and prolonged operational life of the motor components.

Additionally, operating at 90V allows for a more compact motor design. The higher voltage permits the use of thinner wire in windings, reducing the overall size and weight of the motor. This is particularly advantageous in applications where space is limited, such as in electric vehicles and portable machinery. Furthermore, PMDC motors at 90V can achieve higher speeds, making them suitable for high-performance applications. The combination of efficiency, space-saving design, and enhanced speed capabilities makes 90V an attractive choice for engineers and developers looking to optimize motor performance in various industrial and consumer applications.

Exploring the Efficiency and Applications of Permanent Magnet DC Motors at 90V

| Parameter | Value | Units |

|---|---|---|

| Rated Voltage | 90 | V |

| Rated Power | 500 | W |

| Efficiency | 85 | % |

| Max Speed | 3000 | RPM |

| Torque | 1.5 | Nm |

| Weight | 4.5 | kg |

| Application Areas | Industrial Automation, Robotics, Electric Vehicles |

Key Applications of 90V Permanent Magnet DC Motors in Various Industries

Permanent Magnet DC (PMDC) motors operating at 90V are increasingly pivotal in various industries due to their efficiency and compact design. One of the significant trends is the growing demand for energy-efficient solutions that address sustainability concerns. As industries such as oil, chemicals, and food processing strive towards reducing energy consumption and emissions, 90V PMDC motors offer a suitable alternative by providing high torque and precise speed control, making them ideal for applications in conveyor systems and packaging machinery.

The market for Brushless DC (BLDC) motors, which includes 90V PMDC motors, is expected to see substantial growth, bolstered by policies advocating for energy conservation. The industrial motor market in China alone is projected to reach significant revenue figures in the coming years, reflecting a robust growth trajectory. In sectors like robotics and automation, these motors are being utilized in advanced applications, enabling innovations in design and functionality. Their adaptability across various fields underscores their importance in current and future industrial applications.

Comparative Efficiency Analysis of 90V versus Other Voltage Motors

The comparative efficiency analysis between 90V permanent magnet DC motors and those operating at different voltages reveals significant insights into their performance characteristics. Permanent magnet DC motors are known for their high torque-to-weight ratio and efficient performance, making them an attractive choice for many applications. When compared to lower voltage systems, the 90V motors often exhibit enhanced efficiency due to reduced copper losses and improved torque delivery at higher operational levels. This can be particularly beneficial in applications where space and weight considerations are crucial, such as in electric vehicles and robotics.

Additionally, the operational advantages of 90V motors extend to their ability to maintain consistent performance across varying load conditions. This stability enables better energy management, reducing the need for frequent maintenance and enhancing overall system reliability. Conversely, while high-voltage systems provide significant advantages, they also necessitate careful consideration in terms of insulation and safety protocols. The contrast between 90V motors and other voltage options underscores the importance of selecting the right motor type based on the application's specific requirements and constraints, ultimately influencing the overall system efficiency and performance.

Future Trends and Innovations in 90V Permanent Magnet DC Motor Technology

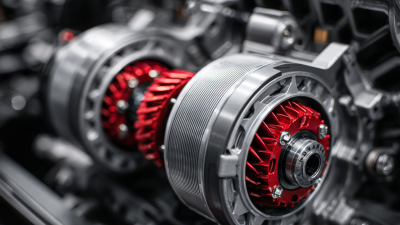

The future of 90V permanent magnet DC motors is set to be revolutionized by ongoing innovations and trends emerging in the electric motor sector. With the surge in electric vehicle (EV) adoption, these motors gain popularity due to their superior efficiency, providing significant torque and power at lower energy consumption levels. Industry data indicates that permanent magnet motors account for over 60% of the traction motor market in EVs, showcasing their critical role in enhancing vehicle performance and sustainability.

Recent technological advancements at events like CES 2024 reveal the potential for even greater efficiencies and versatility in electric motors. Developing technologies focus on maximizing magnetic performance through advanced materials and design, integrating rare earth elements that significantly boost the motor’s power-to-weight ratio. As initiatives like the U.S. rare earth supply chain strategy take shape, the ability to innovate while securing essential materials is paramount to maintaining competitiveness, especially against dominant global players in the clean energy landscape. The push for higher efficiency not only aids in driving down costs but also positions 90V permanent magnet DC motors as a cornerstone of the EV industry's ambitious growth trajectory.

Related Posts

-

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

-

Revolutionizing Robotics: The Essential Role of DC Motor Magnets in Modern Technology

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Exploring the Future of Energy with Permanent Magnet Motor Generators

-

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology