Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

The evolution of electric motors is crucial for enhancing efficiency across various applications, and recent innovations surrounding permanent magnet rotors are at the forefront of this transformation. According to the International Electrotechnical Commission, electric motors account for approximately 45% of the global electricity consumption, emphasizing the urgent need for developments that optimize their performance. Permanent magnet rotors, known for their superior efficiency and compact design, are becoming increasingly important as industries seek to reduce energy consumption and minimize carbon footprints. A report by MarketsandMarkets estimates that the global permanent magnet motor market is expected to grow from USD 21.11 billion in 2021 to USD 39.25 billion by 2026, highlighting the critical role of permanent magnet rotor technology in driving this growth. As we delve into how these innovations can unleash unprecedented efficiency in electric motors, we will explore practical implementation strategies and their implications for various sectors.

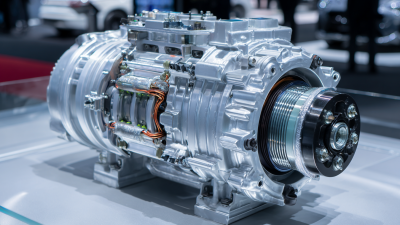

Revolutionizing Electric Motor Design with Permanent Magnet Rotor Technology

Recent advancements in permanent magnet rotor technology are revolutionizing electric motor design, enabling higher efficiency and performance levels previously thought unattainable. According to a report by Research and Markets, the global permanent magnet motor market is expected to grow from $16.75 billion in 2020 to $34.87 billion by 2026, showcasing the increasing demand for more efficient electric motors in various applications, from automotive to industrial sectors.

The incorporation of permanent magnets in rotor designs significantly reduces energy losses, resulting in motors that can achieve efficiencies exceeding 95%. In an electric vehicle context, this translates to extended battery life and greater range, a crucial factor in consumer adoption. Moreover, the shift to permanent magnet synchronous motors (PMSMs) has been noted to enhance torque density, providing higher performance in compact sizes. A study published in the IEEE Transactions on Industrial Electronics highlights that PMSMs can outperform induction motors by up to 30% in specific applications, further solidifying the role of permanent magnet technology in modern electric motor design.

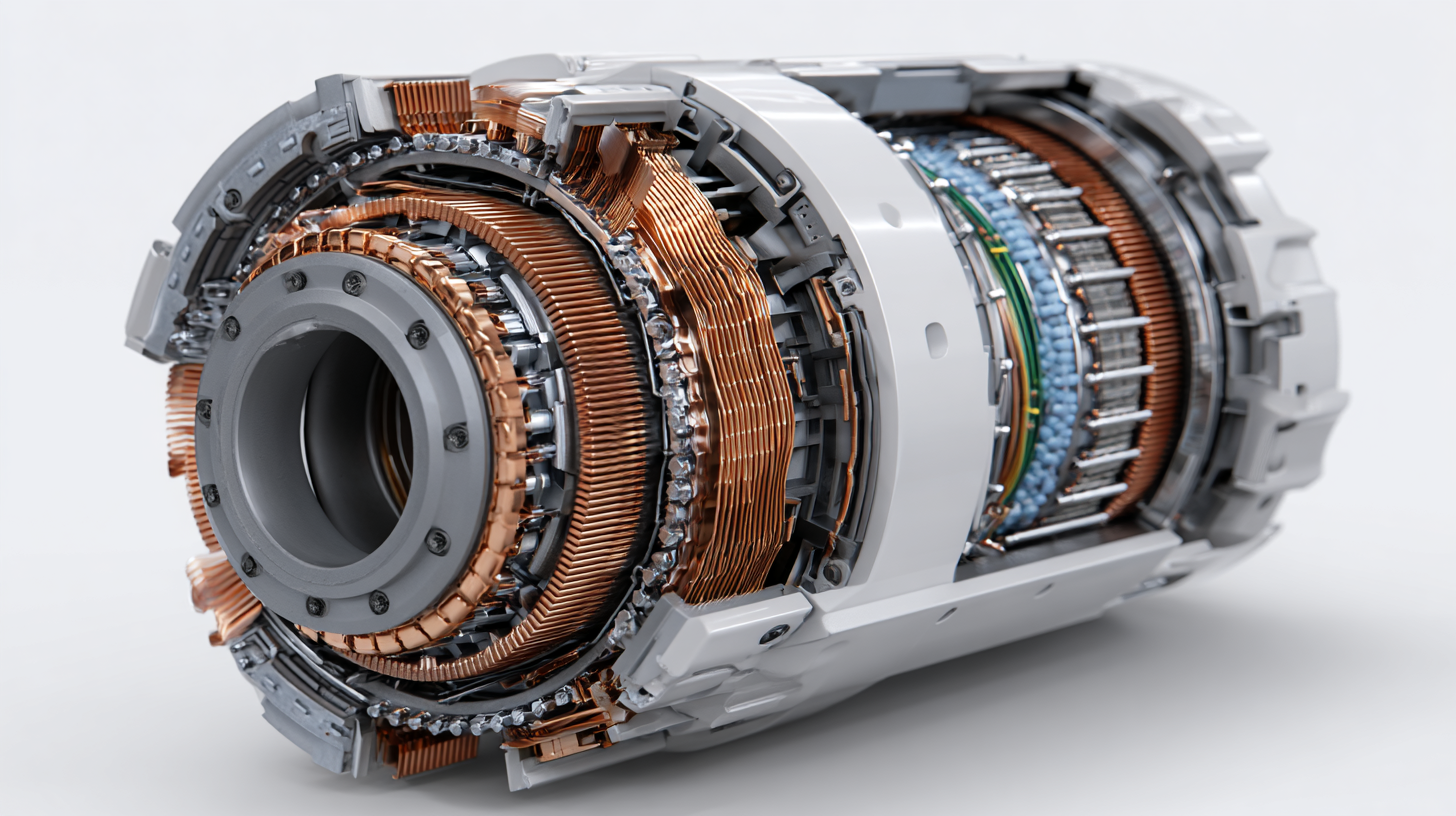

Key Advantages of Permanent Magnet Rotors in Enhancing Motor Efficiency

Permanent magnet rotors have revolutionized the electric motor industry by significantly enhancing efficiency levels. According to the International Energy Agency (IEA), motors account for nearly 45% of global electricity consumption, highlighting the immense potential for energy savings through improved motor technology. Implementing permanent magnet rotors can lead to efficiencies exceeding 95%, compared to traditional wound rotor motors, which typically achieve around 90% efficiency. This increase not only reduces operational costs but also contributes to environmental sustainability through lower energy usage.

**Tip:** When selecting electric motors for new projects, consider those equipped with permanent magnet technology to maximize efficiency and minimize energy consumption.

In addition to efficiency gains, permanent magnet rotors offer greater torque density, enabling smaller and lighter motor designs. Research from the Department of Energy indicates that these innovations can result in a 20-30% reduction in motor size without compromising performance. As industries strive for higher performance and lower energy consumption, the adoption of permanent magnet rotors becomes increasingly strategic.

**Tip:** Evaluate the long-term lifecycle costs of motors with permanent magnet technology against traditional alternatives to make informed purchasing decisions.

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

| Advantage | Description | Impact on Efficiency (%) | Typical Applications |

|---|---|---|---|

| Higher Power Density | Permanent magnet rotors allow for a smaller, lighter motor design. | 10-30% | Electric Vehicles, Drones |

| Reduced Energy Losses | Less heat generation leads to improved thermal efficiency. | 15-25% | Industrial Automation |

| High Torque at Low Speeds | Effective torque production without requiring high RPMs. | 20-40% | Conveyor Systems, Robotics |

| Improved Reliability | Less wear and tear due to fewer moving parts compared to traditional designs. | N/A | Renewable Energy Systems, HVAC |

| Reduced Size and Weight | Compact design saves space and simplifies integration. | 10-20% | Portable Electronics, Electric Bikes |

Innovative Materials Driving Performance in Permanent Magnet Rotors

The innovation of materials in permanent magnet rotors is crucial in enhancing the performance of electric motors, particularly in the push for climate-neutral technologies. Recent advancements highlight the European efforts to replace rare earth elements (REEs) traditionally used in these motors with alternative materials. Research projects are evaluating different composite materials that not only reduce dependency on scarce resources but also potentially improve the efficiency and sustainability of electric motors.

Additionally, the development of magnet-free electric motors exemplifies the strides being made in rotor technology. These innovations prioritize compactness, ensuring that motors are not only powerful but also lighter and easier to integrate into various applications, such as hybrid vehicles. The incorporation of advanced features like passive magnetic bearings enhances the overall performance and reliability of these systems. By continuously optimizing design and material composition, the industry is set to unlock new levels of efficiency in electric motors while addressing critical environmental concerns.

Practical Tips for Integrating Permanent Magnet Rotors in Motor Systems

Integrating permanent magnet rotors into electric motor systems can significantly enhance efficiency and performance. As highlighted by recent innovations, the adoption of advanced design methodologies, including 3D printing, is paving the way for the creation of lightweight electric machines that can be customized for various applications. This is particularly relevant in the development of electric vertical-takeoff-and-landing (eVTOL) aircraft, where reducing weight while maintaining a high power-to-weight ratio is critical.

Moreover, improvements in existing motor technology, such as retrofitting legacy motors to achieve better performance without relying on rare-earth magnets, demonstrate the practicality of permanent magnet integration. With ongoing advancements, manufacturers are encouraged to localize production and invest in in-house powertrain developments, leading to not only increased efficiency but also a more resilient supply chain. Adopting these innovations in permanent magnet rotor technology promises to unlock new applications across diverse sectors, from electric vehicles to aviation, ultimately driving the industry towards a more sustainable future.

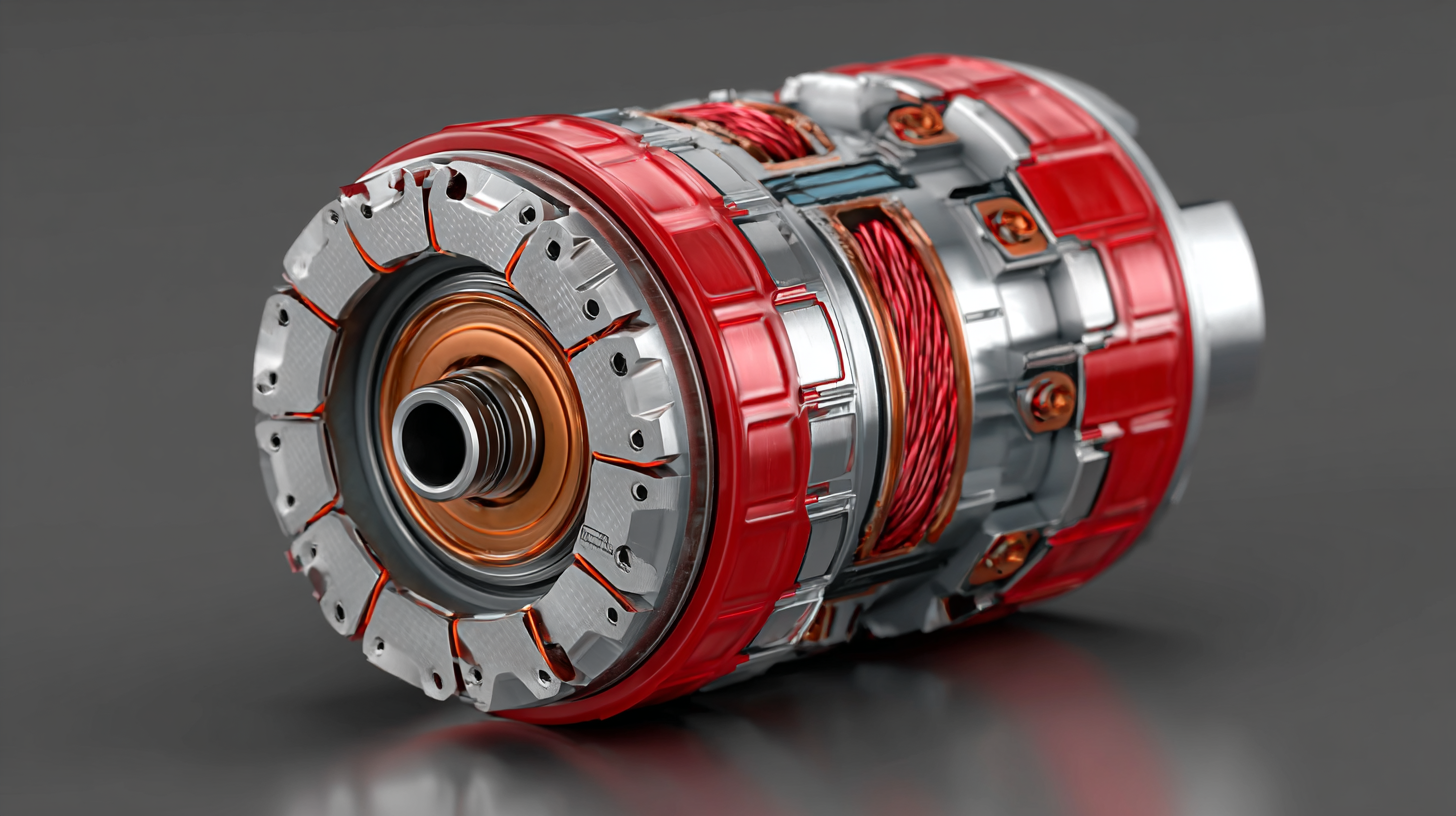

Future Trends in Permanent Magnet Rotor Development and Applications

The evolution of permanent magnet rotor technology is poised to redefine the landscape of electric motors in the coming years. According to a recent report by the International Energy Agency (IEA), the global demand for efficient electric motors is expected to increase by 20% by 2030, driven by the push for energy efficiency and sustainability. Innovations in magnet materials, such as the development of high-performance rare-earth magnets, are set to enhance torque density and reduce energy losses, making electric motors more efficient than ever before.

**Tips:** When selecting a motor for your application, consider the rotor's design and the materials used. The choice of permanent magnet can significantly influence performance and efficiency.

Future trends highlight the integration of smart technology into permanent magnet rotors, enabling predictive maintenance and improved energy management. Research from MarketsandMarkets suggests that the permanent magnet motor market will reach $12 billion by 2025, underscoring the growing emphasis on automation and remote monitoring capabilities. These advancements not only extend the life of the motors but also optimize their performance in real-time applications.

**Tips:** Keep an eye on the latest advancements in magnet technology, as these innovations can impact your investment decisions and operational efficiency. Investing in next-generation rotors can lead to substantial energy savings and lower operational costs in the long run.

Future Trends in Permanent Magnet Rotor Development and Applications

This chart illustrates the projected improvements in efficiency for electric motors with permanent magnet rotors over the next decade. The data reflects advancements in rotor design, materials, and manufacturing processes.