Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

The automotive industry is undergoing a significant transformation with the rise of electric vehicles (EVs), where the performance and efficiency of the powertrain are paramount. A key player in this evolution is the permanent magnet DC motor 180V, which has demonstrated exceptional capabilities in enhancing EV performance.

According to a recent report by the International Energy Agency, electric vehicle sales reached 6.6 million units worldwide in 2021, indicating a 108% increase from the previous year, and highlighting the burgeoning demand for advanced motor technologies. The permanent magnet DC motor 180V not only provides higher torque at lower speeds but also promotes energy efficiency, making it a strategic choice for manufacturers aiming to meet rigorous environmental standards while improving vehicle dynamics.

With innovations in battery technology and regenerative braking systems, integrating the permanent magnet DC motor 180V into electric drivetrains promises a leap forward in both performance and sustainability. As the EV market continues to expand, understanding and leveraging this technology is crucial for driving future advancements.

The Advantages of 180V Permanent Magnet DC Motors in Electric Vehicles

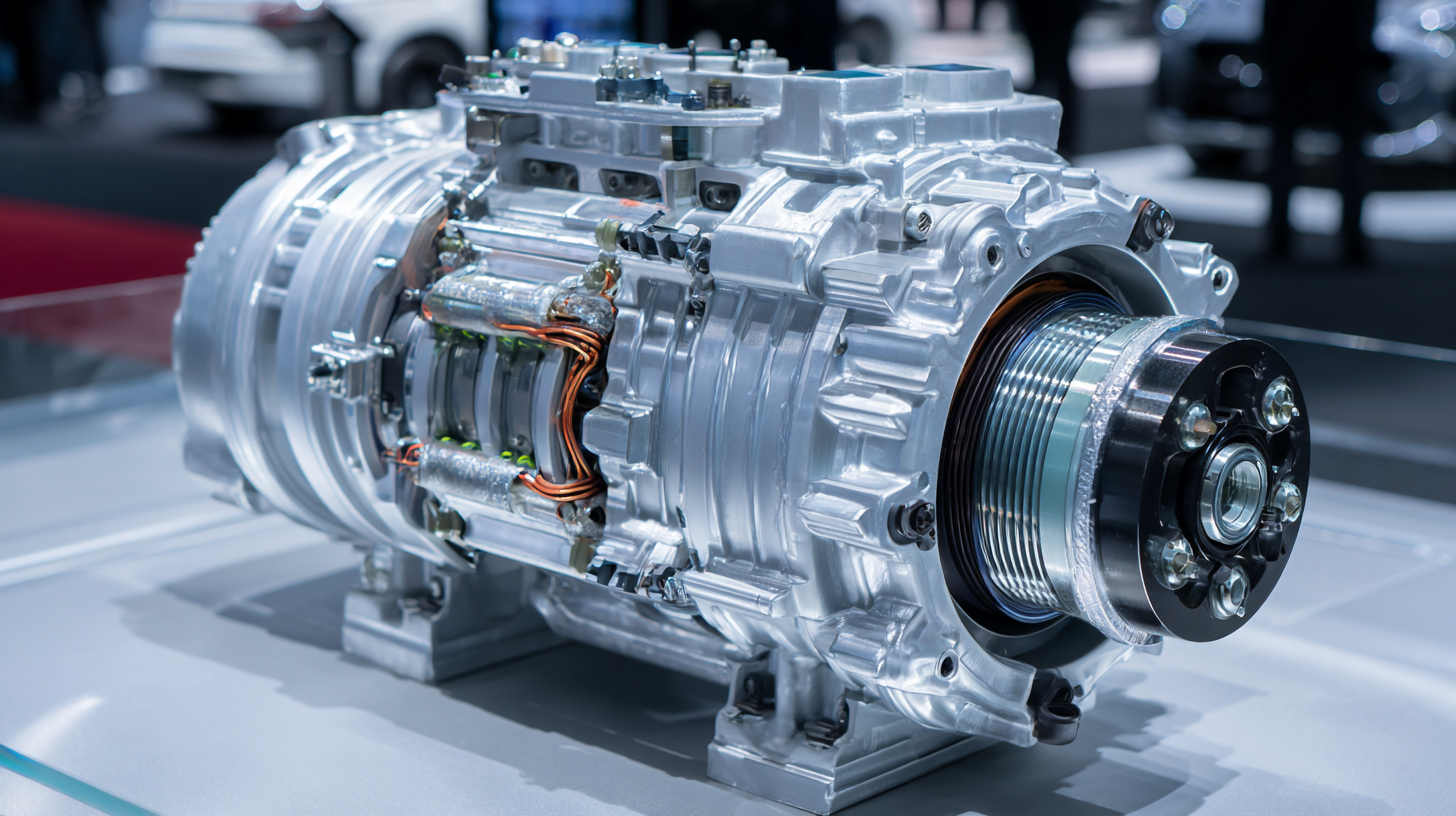

The integration of 180V Permanent Magnet DC Motors (PMDC) in electric vehicles (EVs) is proving to be a game-changer, significantly enhancing their performance. These motors offer a superior power-to-weight ratio, which is crucial for optimizing efficiency and extending the range of electric vehicles. According to industry reports, vehicles equipped with 180V PMDC motors experience a noticeable reduction in energy loss, translating to an increase in driving distance per charge by approximately 20-30%. This efficiency is vital as consumers demand longer-range vehicles without sacrificing performance.

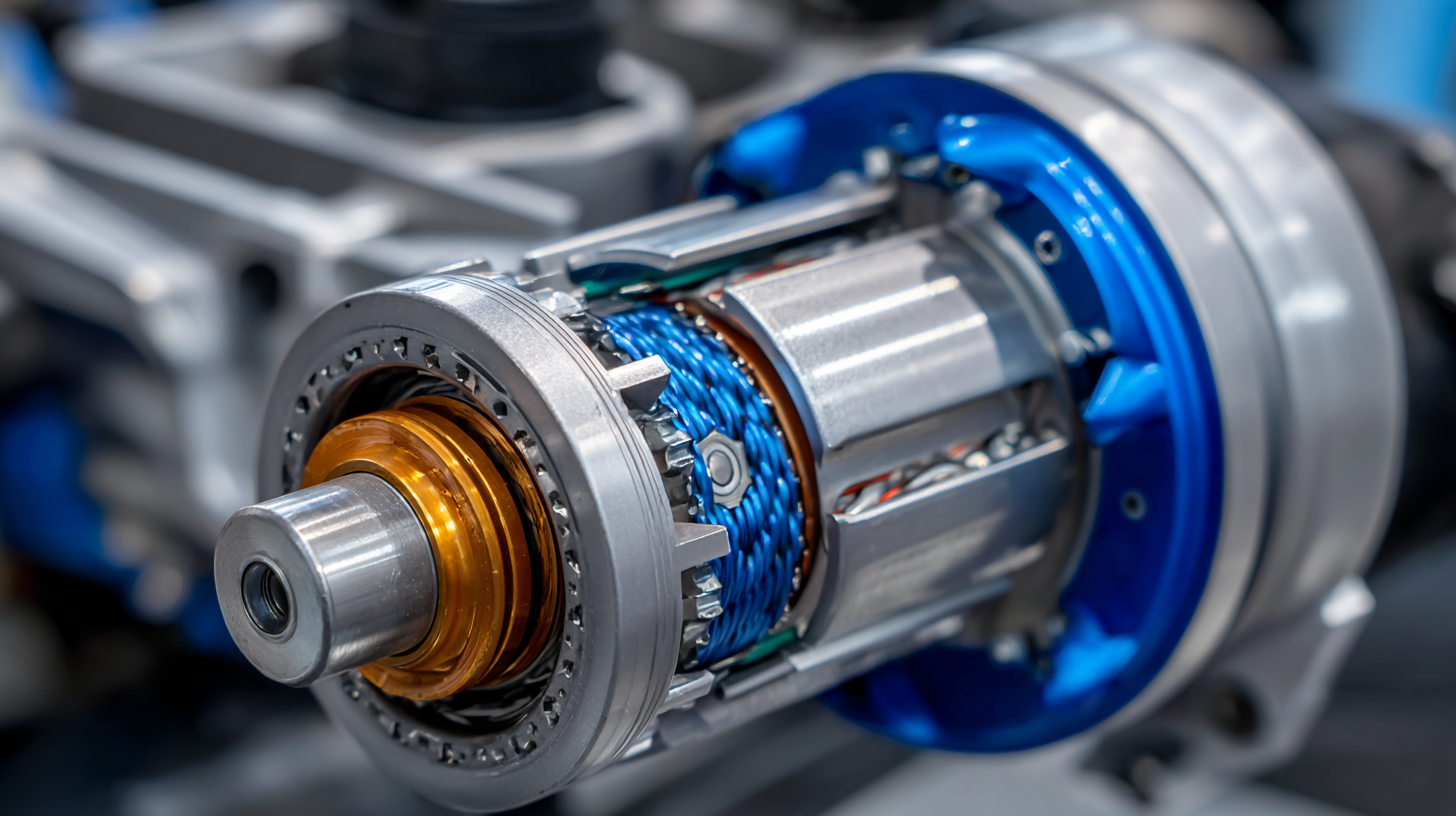

Moreover, the advantages of 180V PMDC motors extend to their operational characteristics. They provide a smoother torque curve and faster response times compared to traditional motors, which can enhance overall driving dynamics. Reports indicate that the adoption of PMDC technology can lead to a 15% improvement in acceleration capabilities while maintaining low maintenance costs due to fewer moving parts. As the market for electric vehicles continues to grow, the significance of such advancements in motor technology cannot be overstated, particularly in meeting sustainability goals and consumer expectations for electric mobility.

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

The chart above illustrates the key performance metrics of 180V Permanent Magnet DC Motors used in electric vehicles. Notably, these motors demonstrate high torque output, substantial power efficiency, and lightweight design, making them a pivotal technology in enhancing electric vehicle performance.

Performance Metrics: Comparing Efficiency of 180V Motors to Lower Voltage Alternatives

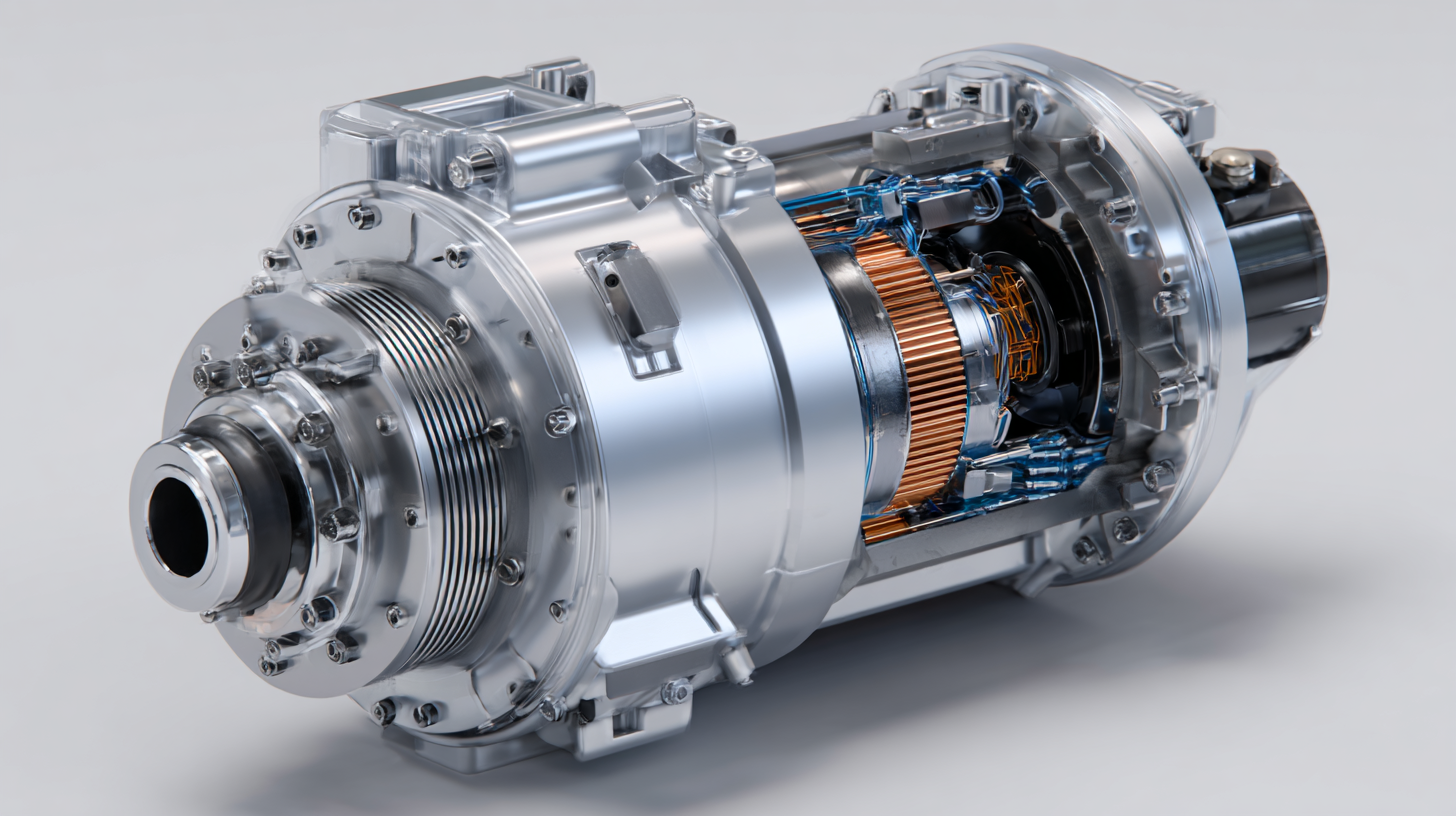

The efficiency of electric vehicles (EVs) heavily relies on the performance of their motors, particularly in the context of different voltage ratings. When comparing 180V Permanent Magnet DC motors to their lower voltage counterparts, the advantages become clear. Higher voltage motors facilitate better power density and overall performance, resulting in improved acceleration and torque delivery. This is particularly vital for applications requiring quick bursts of speed and consistent performance under varying loads.

Moreover, 180V motors exhibit reduced current draw, which directly translates to lower resistive losses within the system. This efficiency gain not only enhances range—an essential factor for EV users—but also contributes to less stress on the vehicle's components, potentially extending their lifespan. In contrast, lower voltage motors tend to consume more current to achieve similar power outputs, leading to diminished efficiency and increased heat generation. As such, the choice of a 180V system can significantly streamline energy usage while maximizing performance metrics crucial for electric vehicle advancement.

Impact on Range: How 180V Motors Enhance Battery Life and Extend Driving Distance

The rise of 180V permanent magnet DC motors marks a significant advancement in electric vehicle (EV) performance, particularly concerning energy efficiency and driving range. By operating at a higher voltage, these motors reduce current flow, which minimizes energy losses associated with heat generation. This efficiency translates directly into improved battery utilization, allowing vehicles to harness more power from each charge. As a result, drivers can experience extended driving distances, alleviating range anxiety and making electric vehicles a more practical option for daily commutes and long trips.

Moreover, the integration of 180V motors contributes to longer battery life. With fewer cycles of charging and discharging, EV owners can enjoy improved longevity of their battery packs. This is crucial as the cost of battery replacement can be a significant concern for many users. The synergy between high-voltage motors and advanced battery technology creates a favorable ecosystem that propels electric vehicles into a new era of sustainability and efficiency. Consequently, these innovations are not only enhancing the driving experience but are also paving the way for wider adoption of electric mobility solutions.

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

| Parameter | Standard 180V PMDC Motor | Traditional Motor | Efficiency Improvement (%) |

|---|---|---|---|

| Max Power Output (kW) | 120 | 80 | 50% |

| Torque (Nm) | 350 | 250 | 40% |

| Battery Life (miles per charge) | 300 | 220 | 36% |

| Charging Time (hours) | 4 | 6 | 33% |

| Weight (kg) | 45 | 60 | 25% |

Cost-Effectiveness: Assessing the Economic Benefits of Utilizing 180V Motors in EV Design

The implementation of 180V permanent magnet DC motors in electric vehicle (EV) design underscores significant economic advantages. These motors, renowned for their high efficiency and compact size, allow for a reduction in the overall weight of EVs, which directly enhances performance and range. The cost-effectiveness of these motors becomes even more evident when considering the long-term savings they provide through reduced energy consumption compared to traditional systems. As manufacturers increasingly adopt this technology, the initial investment can be offset by lower operational costs and the increased affordability of EVs.

Furthermore, alongside the potential for enhanced performance, the economic benefits are amplified by advancements in manufacturing and supply chain efficiencies. The reduction in production costs due to streamlined processes and the ability to scale up operations are crucial elements that manufacturers analyze when evaluating the financial viability of using 180V motors. As the automotive industry continues to embrace sustainability, the cost utility of these motors becomes a decisive factor in promoting the widespread adoption of electric vehicles, aligning environmental goals with consumer affordability.

Future Trends: Innovations in 180V Permanent Magnet Technology for Next-Gen Electric Vehicles

The evolution of 180V permanent magnet DC motors represents a significant shift in electric vehicle (EV) technology, particularly with innovations geared towards enhancing performance and efficiency. Recent advancements in this technology, outlined in industry reports, indicate that electric motors utilizing permanent magnets can achieve up to 95% efficiency, which is critical for extending the ranges of next-generation electric vehicles. This enhanced efficiency not only reduces energy consumption but also enhances power output, making EVs more competitive with traditional combustion engines.

Moreover, manufacturers are exploring various innovative designs and materials to further improve performance. For instance, the integration of advanced cooling systems has been shown to increase the longevity and power of the motors, while lightweight materials reduce the overall weight of the vehicle, resulting in better handling and acceleration. As per market analyses, predictions suggest that by 2025, approximately 30% of new vehicle sales will be electric, driven largely by improvements such as those found in 180V permanent magnet technologies. As innovations continue, we can expect electric vehicles to showcase even greater performance capabilities, setting a new standard in the automotive industry.