Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

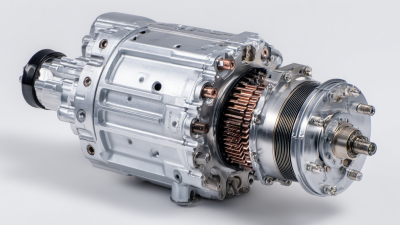

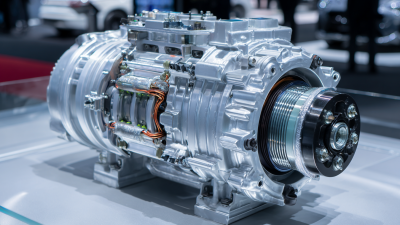

The integration of magnets for motors has revolutionized various sectors within modern technology, driving efficiency and innovation. According to a report by the International Electrotechnical Commission, the global market for electric motors is projected to reach $150 billion by 2026, with a significant push coming from advancements in magnet technology. This shift highlights the increasing reliance on high-performance magnets, specifically in applications such as electric vehicles, robotics, and renewable energy systems.

Research from the Department of Energy indicates that motors equipped with advanced magnets can achieve energy efficiency levels exceeding 95%, underscoring their importance in reducing operational costs and enhancing performance. As we delve into the science behind the utilization of magnets in motors, we uncover not only the technical advantages they provide but also their pivotal role in driving sustainable advancements in technology.

Advancements in Magnet Technology: Revolutionizing Motor Design and Efficiency Metrics

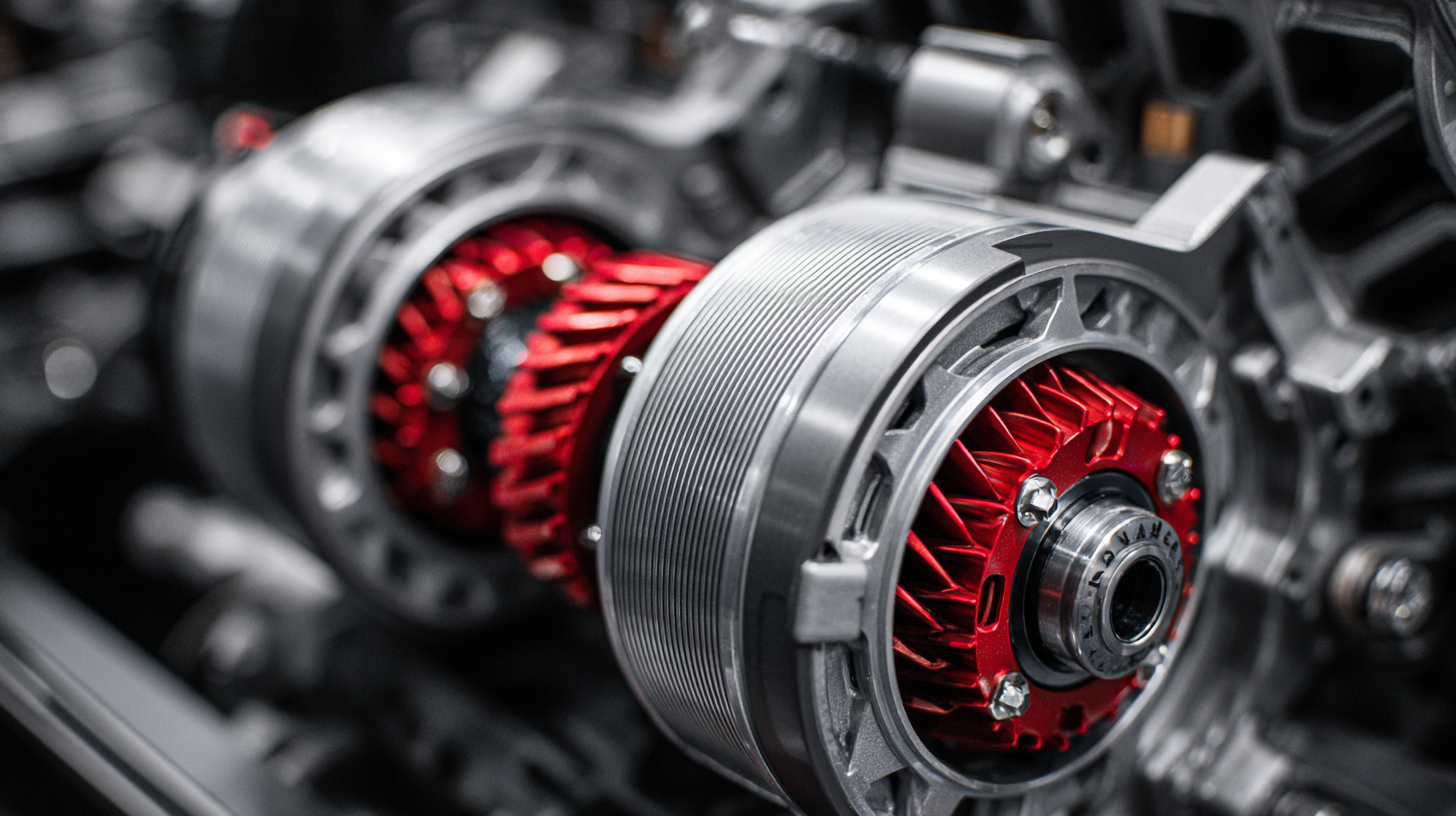

Advancements in magnet technology are driving a paradigm shift in motor design and efficiency metrics, particularly in sustainable electric vehicles. The emergence of brushless and magnet-free motors represents a significant leap, enabling reductions in environmental impact by as much as 40%. By eliminating the need for traditional magnets, these innovations lead to lighter, more efficient designs that enhance overall performance while also minimizing the carbon footprint of electric mobility solutions.

In parallel, the integration of sophisticated technologies into e-bike conversions further exemplifies the trend towards sustainability in mobility. Such solutions empower users to transform conventional bicycles into electric-powered vehicles effortlessly, promoting eco-friendly transportation options. Furthermore, advancements in electric propulsion systems, like the latest electric motors for aviation, showcase the efficacy of permanent magnet technology in providing both efficiency and power. As the automotive and transportation sectors continue to evolve, magnet technology will remain pivotal in shaping a sustainable future, optimizing performance while aligning with environmental goals.

Advancements in Magnet Technology and Their Impact on Motor Efficiency

This bar chart illustrates the improvements in motor efficiency percentages attributed to advancements in magnet technology over recent years. The data reflects various types of motors that incorporate advanced magnet designs.

The Role of Magnetic Fields in Enhancing Motor Performance: Key Figures and Case Studies

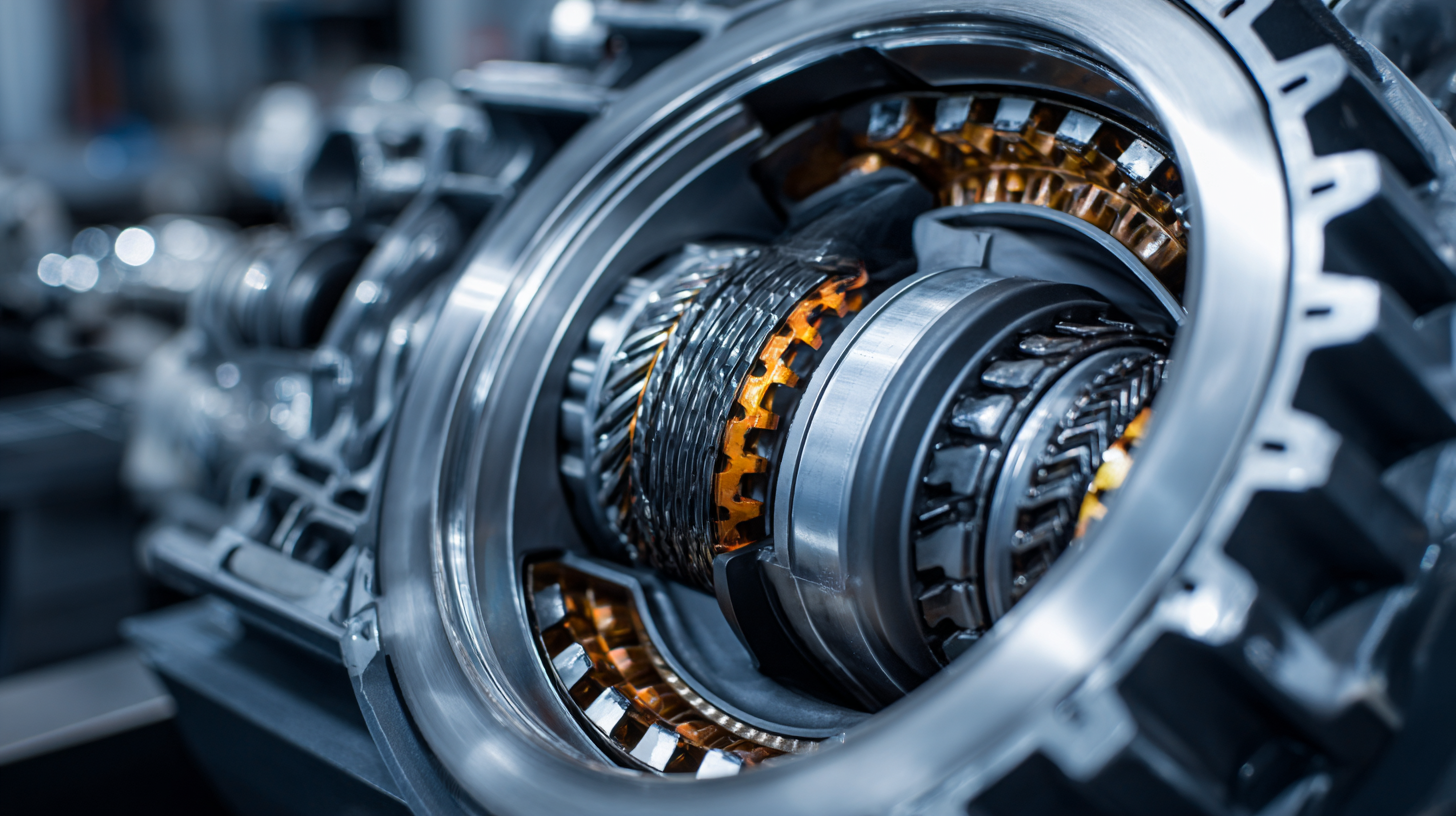

The integration of magnets into motor technology has revolutionized performance in modern applications, particularly in devices like cordless vacuum cleaners. By leveraging magnetic fields, these motors achieve high efficiency and reduced noise levels, essential for user-friendly design. Key figures from recent studies indicate that the right magnetic algorithms can lead to significant improvements in energy consumption without compromising on power output.

A case study highlights the implementation of weak magnetic algorithms in vacuum cleaners, which optimizes motor functions for better energy distribution. This approach not only extends battery life but also enhances suction power, making the device more effective in various cleaning tasks. The KY32MS024 main control chip plays a crucial role in facilitating this technology, enabling precise control over motor operations.

**Tips:** When considering the efficiency of your motor-driven devices, look for those that utilize advanced magnetic field technologies. Additionally, pay attention to product specifications regarding noise levels, as quieter operations can significantly improve your experience. Finally, always research user reviews to gauge real-world performance linked to these innovations.

Quantitative Analysis of Energy Savings: Magnetic Motors vs. Traditional Motors

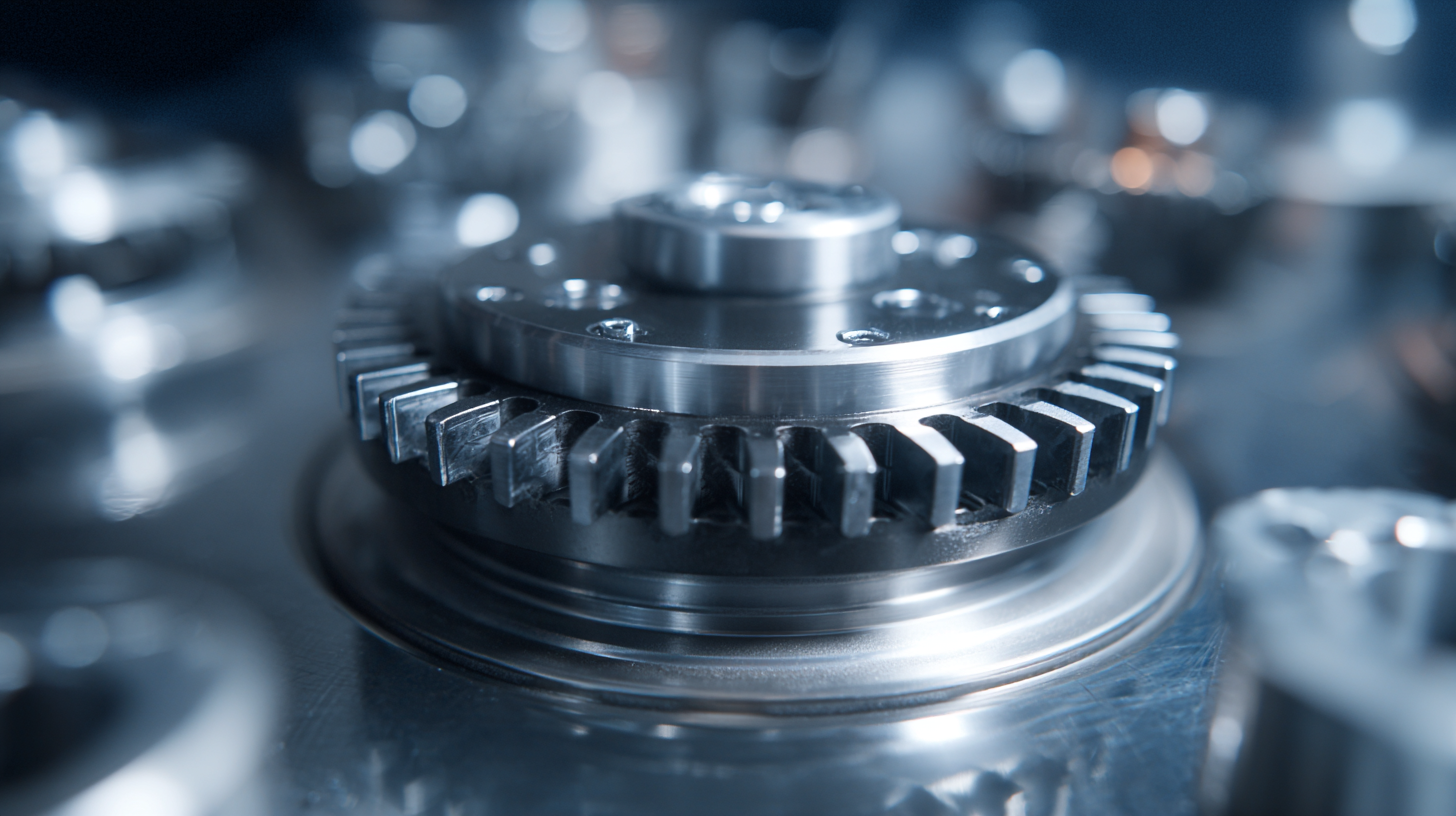

The transition from traditional motors to magnetic motors represents a significant shift in efficiency and energy savings. A quantitative analysis reveals that magnetic motors, leveraging innovations in electromagnetic technology, can provide substantial advantages over their conventional counterparts. For instance, magnetic motors often exhibit higher efficiency ratings, directly translating to reduced energy consumption and operational costs. As industries seek to optimize performance while minimizing their carbon footprints, the adoption of magnetic motors is becoming increasingly attractive.

Additionally, the growth of the energy-efficient motor market underscores a broader trend towards sustainability in technology. With projections showing a steady rise in market size, businesses are taking a closer look at options that not only enhance operational productivity but also align with environmental goals. This is particularly relevant in sectors like logistics, where the implementation of electric vehicles and energy-efficient motors can drastically reduce emissions while maintaining high performance. The integration of magnetic technologies represents a forward-thinking approach to achieving these objectives, ultimately fostering a more sustainable industrial landscape.

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

| Motor Type | Efficiency (%) | Energy Consumption (kWh) | Cost of Operation ($/year) | Maintenance Frequency (times/year) |

|---|---|---|---|---|

| Traditional AC Motor | 85 | 15,000 | 1,200 | 2 |

| Traditional DC Motor | 80 | 16,000 | 1,500 | 3 |

| Magnetic Motor | 95 | 10,000 | 900 | 1 |

| High-Efficiency Motor | 90 | 12,500 | 1,100 | 2 |

Future Trends in Magnet Utilization: A 2025 Industry Forecast for Electric Motors

The future of magnet utilization in electric motors is poised for significant transformation, especially as we look towards 2025 and beyond. The global ferrite magnet market is expected to surge from $10.0 billion in 2025 to $16.4 billion by 2032, reflecting a robust growth trajectory driven by the increasing demand for electric motors across multiple sectors. Moreover, the U.S. rare earth elements market is forecasted to grow by 9.5% from 2025 to 2032, indicating a shift in focus towards sustainable and diversified sources of these critical materials.

**Tips for Engaging with Emerging Trends**:

1. Stay informed about innovations in magnetic technologies, as breakthroughs can significantly influence motor efficiency and performance.

2. Consider the implications of sourcing rare earth materials from alternative markets to mitigate risks associated with supply chain disruptions.

3. Explore partnerships with companies specializing in advanced materials that leverage the latest advancements in magnet technology.

As electric vehicles become more mainstream, the demand for high-performance electric motors will only increase, creating opportunities for businesses to thrive by adapting to these trends. The rise of soft magnetic composites and magnetic sensors further exemplifies the evolving landscape, emphasizing the pivotal role magnets will play in the future of modern technology.

Sustainability in Engineering: How Magnetic Drives Reduce Environmental Impact and Resource Use

In today's rapidly evolving tech landscape, integrating magnetic drives in motors presents a path toward sustainability in engineering. These innovative systems not only enhance operational efficiency but also significantly reduce environmental impact and resource use. According to a report by the International Energy Agency, the shift to electromagnetic systems can lead to energy savings of up to 30% compared to traditional mechanical systems. This efficiency translates to reduced carbon footprints and less waste in the production cycle.

Furthermore, magnetic drives contribute to resource conservation by minimizing the use of rare materials typically required in conventional motor construction. A study published in the Journal of Cleaner Production shows that utilizing permanent magnets can decrease the dependency on limited resources, thus prolonging their availability for future generations. Companies adopting these technologies are also witnessing lower maintenance costs due to fewer moving parts, which enhances both economic and environmental sustainability.

Tip: When considering a transition to magnetic drive systems, evaluate your operational needs carefully. Assess both upfront investment and long-term savings to ensure you maximize the benefits of efficiency and sustainability.

Tip: Stay informed about advancements in magnet technology, as ongoing research and development may present new opportunities for enhancing energy efficiency in your engineering projects.

Related Posts

-

Revolutionizing Robotics: The Essential Role of DC Motor Magnets in Modern Technology

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

-

Exploring the Future of Energy with Permanent Magnet Motor Generators

-

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency