10 Essential Tips for Choosing the Right Magnets for Motors

In the rapidly evolving landscape of electric motors, the selection of appropriate magnets is crucial for optimizing performance and efficiency. According to the latest report from the International Electrotechnical Commission (IEC), the magnets for motors market is set to experience a significant growth, projected to reach $10 billion by 2025, driven by the increasing demand for electric vehicles and renewable energy sources. Industry expert Dr. Emily Chen, a leading researcher in electromagnetism, emphasizes, "The choice of magnets for motors not only influences operational efficiency but also impacts overall sustainability goals."

Selecting the right magnets for motors involves careful consideration of various factors, including material type, size, and magnetic strength. With the advancement of technologies in permanent magnet materials like neodymium and ferrite, manufacturers now have a broader spectrum of options at their disposal. As noted in a recent study published by the Journal of Magnetic Materials, using high-performance magnets can enhance motor efficiency by up to 30%, thereby reducing energy consumption and operational costs. This underscores the importance of making informed decisions to harness the full potential of magnets for motors in modern applications.

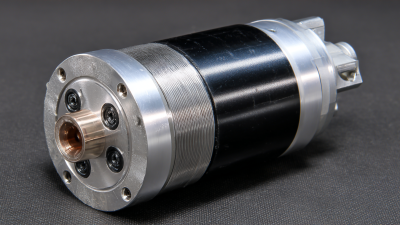

Understanding Different Magnet Types: Permanent vs. Electromagnets in Motor Applications

When selecting magnets for motors, understanding the differences between permanent magnets and electromagnets is crucial. Permanent magnets, like neodymium, are preferred in many cases due to their high magnetic strength and stability. According to industry reports, these magnets are essential in applications such as electric vehicle (EV) motors, where high efficiency is required. However, the reliance on rare earth elements poses significant challenges, including supply chain vulnerabilities and environmental concerns. Recent innovations are exploring alternative approaches to magnet design, which could reduce or eliminate the need for rare earth materials.

Electromagnets offer a flexible alternative in motor applications, with their magnetic strength adjustable depending on the current. This adaptability makes them particularly suited for certain high-performance settings, such as hybrid electric vehicles, where optimizing performance under varying conditions is critical. Studies indicate a growing interest in brushless DC and switched reluctance motors, which leverage these electromagnetic principles to deliver enhanced efficiency and reliability while mitigating some of the drawbacks associated with permanent magnet motors. As the industry shifts towards more sustainable practices, the comparative advantages of traditional magnet types will play a crucial role in shaping future motor designs.

Magnet Material Selection: Analyzing Neodymium, Samarium-Cobalt, and Ferrite Properties

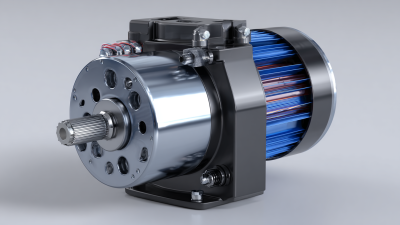

The global permanent magnet market is on an impressive trajectory, projected to reach USD 88.51 billion by 2030, growing at a compound annual growth rate (CAGR) of 8.5%. This robust growth is driven by the increasing demand for advanced magnetic materials across various applications, particularly in consumer electronics, automotive industries, and renewable energy sectors. Among the prominent types of magnets being utilized, neodymium, samarium-cobalt, and ferrite magnets show distinct properties that dictate their suitability for specific motor applications.

Neodymium magnets, known for their high magnetic strength, are preferred in electric vehicles and wind turbine applications, where efficiency and power density are critical. Meanwhile, samarium-cobalt magnets offer excellent thermal stability and corrosion resistance, making them ideal for high-temperature environments. On the other hand, ferrite magnets, while less powerful, are cost-effective and widely used in consumer electronics. As the demand for magnets evolves, the quest for sustainable alternatives, particularly magnets that do not rely on rare earth elements, is becoming a focal point in the industry, greatly influencing material selection trends and market dynamics.

10 Essential Tips for Choosing the Right Magnets for Motors

| Magnet Type | Material | Magnetic Strength (Br) | Temperature Resistance | Cost (Approx. USD/kg) | Applications |

|---|---|---|---|---|---|

| Neodymium | NdFeB | 1.2 - 1.4 T | -40 to 80 °C | 40 - 150 | Electric motors, speakers, generators |

| Samarium-Cobalt | SmCo | 1.1 - 1.3 T | -40 to 300 °C | 80 - 200 | High-temperature applications, precision motors |

| Ferrite | BaFe | 0.3 - 0.45 T | -40 to 250 °C | 5 - 15 | Low-cost motors, household appliances |

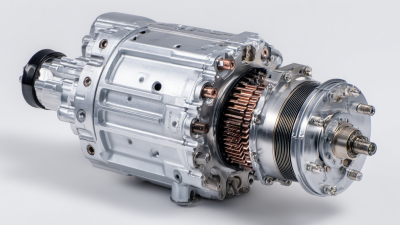

Magnet Shape and Size: How Dimensions Impact Motor Efficiency and Performance

When choosing the right magnets for motors, understanding the impact of magnet shape and size on motor efficiency and performance is crucial. The dimensions of the magnets play a significant role in defining their magnetic strength and the overall effectiveness of the motor. For instance, larger magnets can provide greater magnetic flux, which enhances the torque output. However, it's essential to balance size with the motor design to ensure that it fits within the constraints of the application.

One essential tip is to consider the geometry of the magnets. Different shapes, such as cylindrical or rectangular, can influence the magnetic field distribution, impacting the motor's performance. Additionally, the thickness of the magnets should be optimized to minimize losses while maximizing efficiency. This is particularly important in applications like electric vehicles, where even minor improvements in efficiency can lead to significant increases in performance and range.

Moreover, selecting the right material is equally important. High-performance materials can sustain higher temperatures and provide better durability, which is vital for both motor longevity and efficiency. As innovation in motor technologies progresses, such as the development of rare-earth free magnets and advanced winding techniques, staying informed about these advancements will help in making the most suitable choices for specific motor applications.

Impact of Magnet Shape and Size on Motor Efficiency

Assessing Magnetic Field Strength: Calculating Required Force for Optimal Motor Function

When selecting magnets for motors, one critical aspect is assessing the magnetic field strength required for optimal motor function. The magnetic field strength directly influences the motor's efficiency and output performance. To calculate the required force, it's essential to consider the specifications of the motor, including its size, load capacity, and application. By understanding these parameters, you can determine the appropriate magnetic strength to ensure that the motor operates effectively within its intended application.

Calculating the required force involves understanding the relationship between the current flowing through the motor and the torque it generates. This requires knowledge of the motor's design and the characteristics of the magnets being used. Utilizing tools such as magnetic field calculators and torque equations can help provide precise measurements. By ensuring the magnets provide adequate force tailored to the motor's needs, you can enhance performance and prevent issues like overheating or insufficient torque generation, leading to a more reliable and efficient motor operation.

Cost vs. Performance: Balancing Budget Constraints with Magnet Quality in Motor Design

When selecting magnets for motor applications, striking the right balance between cost and performance is crucial. According to a report from the International Energy Agency (IEA), magnetic material choice can influence the overall efficiency of electric motors by as much as 20%. This makes it imperative for engineers to assess the type of magnet that offers the necessary performance without overspending. For example, neodymium magnets, while more expensive, provide higher energy density and can reduce the size and weight of motor designs, potentially lowering overall manufacturing costs.

However, the push for cost reduction often leads manufacturers to opt for lower-quality magnets. A study published in the Journal of Magnetic Materials indicates that using inferior magnets can reduce motor life expectancy and operational efficiency, leading to higher total lifecycle costs. Therefore, it's essential to evaluate long-term performance metrics and maintenance considerations when weighing the upfront costs of magnet choices. By integrating performance data and total cost analysis, engineers can make informed decisions that align with budget constraints while maintaining motor effectiveness.

Related Posts

-

Unlocking Efficiency: How IPM SynRM Motors Revolutionize Modern Industrial Applications

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

How to Choose the Right IPM SynRM Motor for Your Next Project

-

2025 Top 5 Permanent Magnet DC Motor 180V Options for Enhanced Performance

-

What is a Permanent Magnet DC Motor 90V and How Does it Work

-

Exploring the Efficiency and Applications of Permanent Magnet DC Motors at 90V