Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

In an era where energy efficiency is paramount, the emergence of technologies such as the imperial electric permanent magnet motor represents a significant advancement in industrial applications. According to the U.S. Department of Energy, permanent magnet motors can achieve efficiency ratings exceeding 95%, compared to traditional induction motors, which often range between 85% and 90%. These enhanced efficiency levels not only lead to substantial reductions in operational costs but also contribute to decreased greenhouse gas emissions, aligning with global sustainability goals. As industries strive to meet stricter regulations and consumer demand for eco-friendly solutions, the integration of imperial electric permanent magnet motors into manufacturing and transportation systems is poised to unlock significant energy savings and pave the way for a more sustainable future. As reported by various market analyses, the global permanent magnet motor market is anticipated to grow at a compound annual growth rate (CAGR) of over 8% in the coming years, underscoring the transformative potential of this technology.

Benefits of Imperial Electric Permanent Magnet Motors for Energy Efficiency Improvement

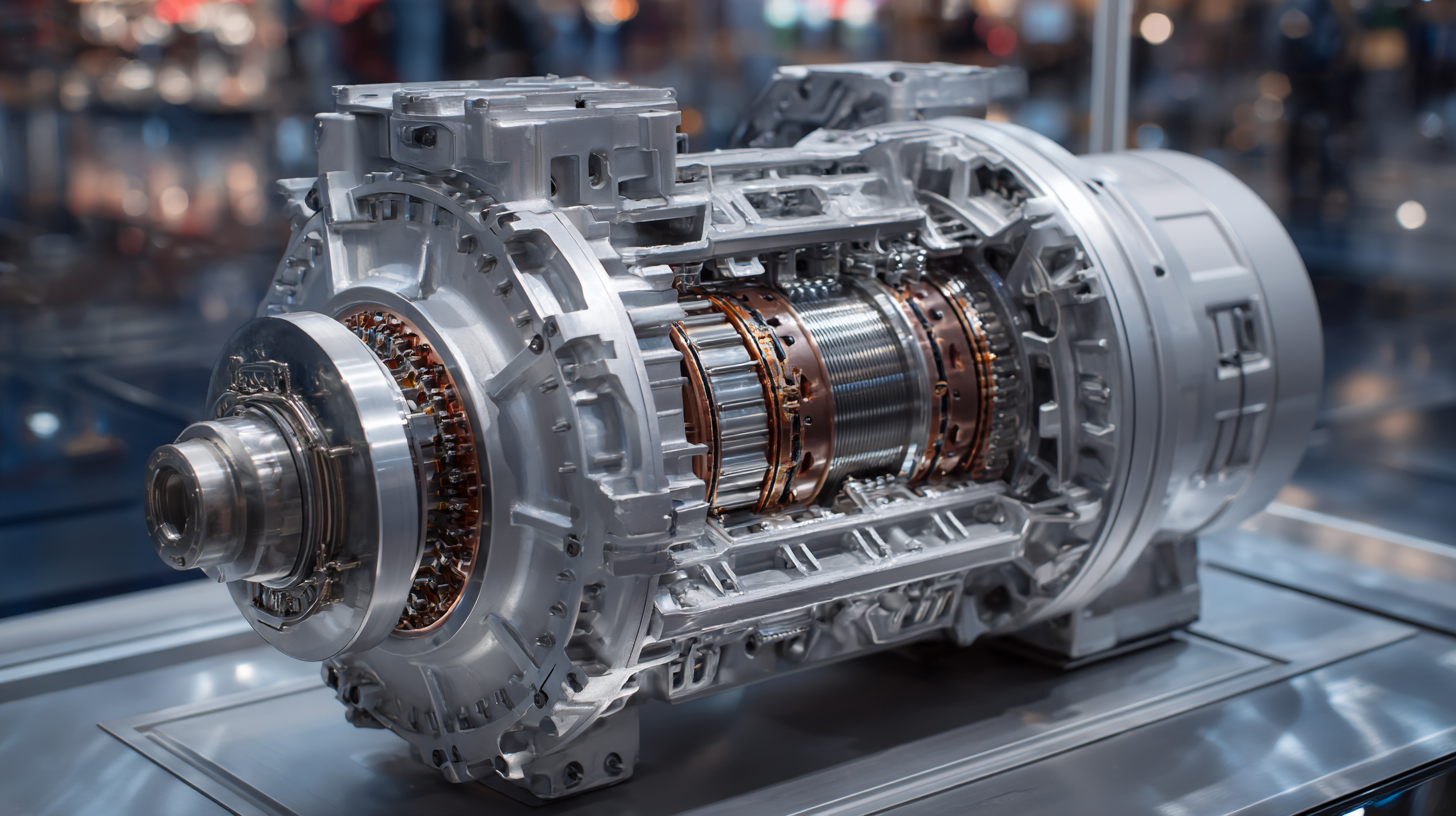

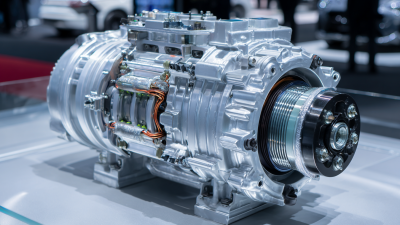

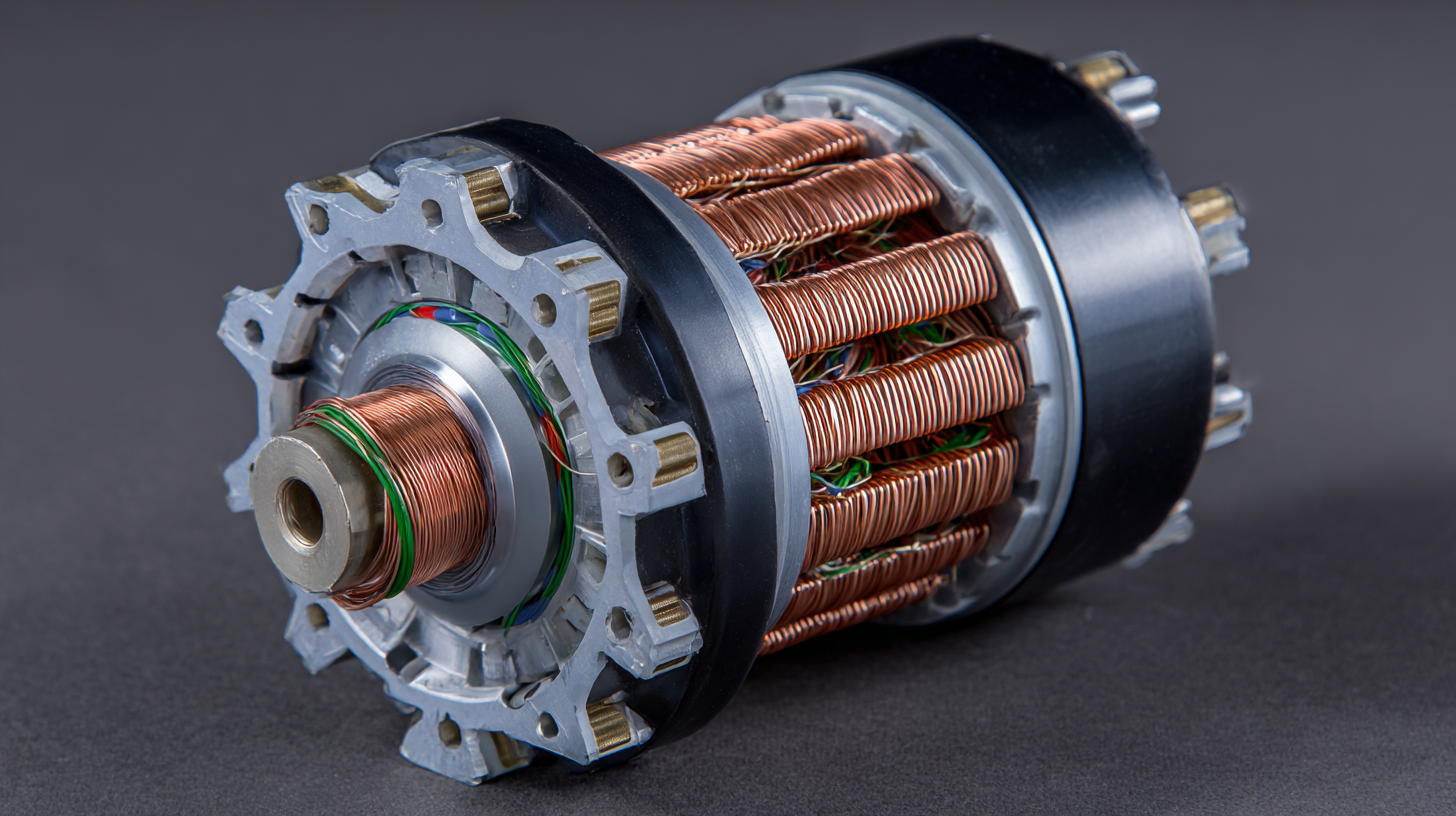

Imperial Electric Permanent Magnet Motors are poised to revolutionize energy efficiency in various applications. These motors utilize permanent magnets instead of traditional electromagnets, significantly reducing energy consumption while enhancing performance. One major advantage is their high efficiency at both low and high speeds, leading to reduced operational costs and lower emissions. Businesses and industries can greatly benefit from implementing these motors, as they contribute to sustainability goals while maintaining productivity levels.

Furthermore, the compact design of Imperial Electric Permanent Magnet Motors allows for easier integration into existing systems, minimizing the need for extensive modifications. Their lightweight nature also ensures compatibility with modern technologies, such as electric vehicles and renewable energy sources. By choosing these advanced motors, companies not only improve their energy efficiency but also future-proof their operations against evolving energy standards and environmental regulations. This strategic investment ultimately leads to a more sustainable and economically advantageous future.

Comparative Analysis: Traditional Motors vs. Permanent Magnet Motors in Energy Consumption

In the realm of electric motors, energy efficiency stands at the forefront of technological advancements. Traditional motors, often relying on induction principles, exhibit inherent energy losses due to rotor resistance and slip. These inefficiencies can lead to increased operational costs and higher carbon footprints. For instance, during start-up and under varying load conditions, traditional motors can consume significantly more energy than necessary, raising concerns for industries seeking sustainable solutions.

Conversely, permanent magnet motors (PMMs) leverage high-energy magnets to achieve remarkable efficiency. By eliminating the rotor losses associated with induction motors, PMMs deliver consistent performance across a wide range of speeds and loads. This increased efficiency translates to lower energy consumption, often exceeding 20% compared to traditional counterparts. Additionally, PMMs provide superior torque density, which not only enhances performance but also reduces the overall size and weight of the motor. As industries shift toward more sustainable practices, the comparative advantages of permanent magnet motors become increasingly compelling, paving the way for a greener future in energy consumption.

Industry Adoption Rates: Increasing Use of Permanent Magnet Motors in Key Sectors

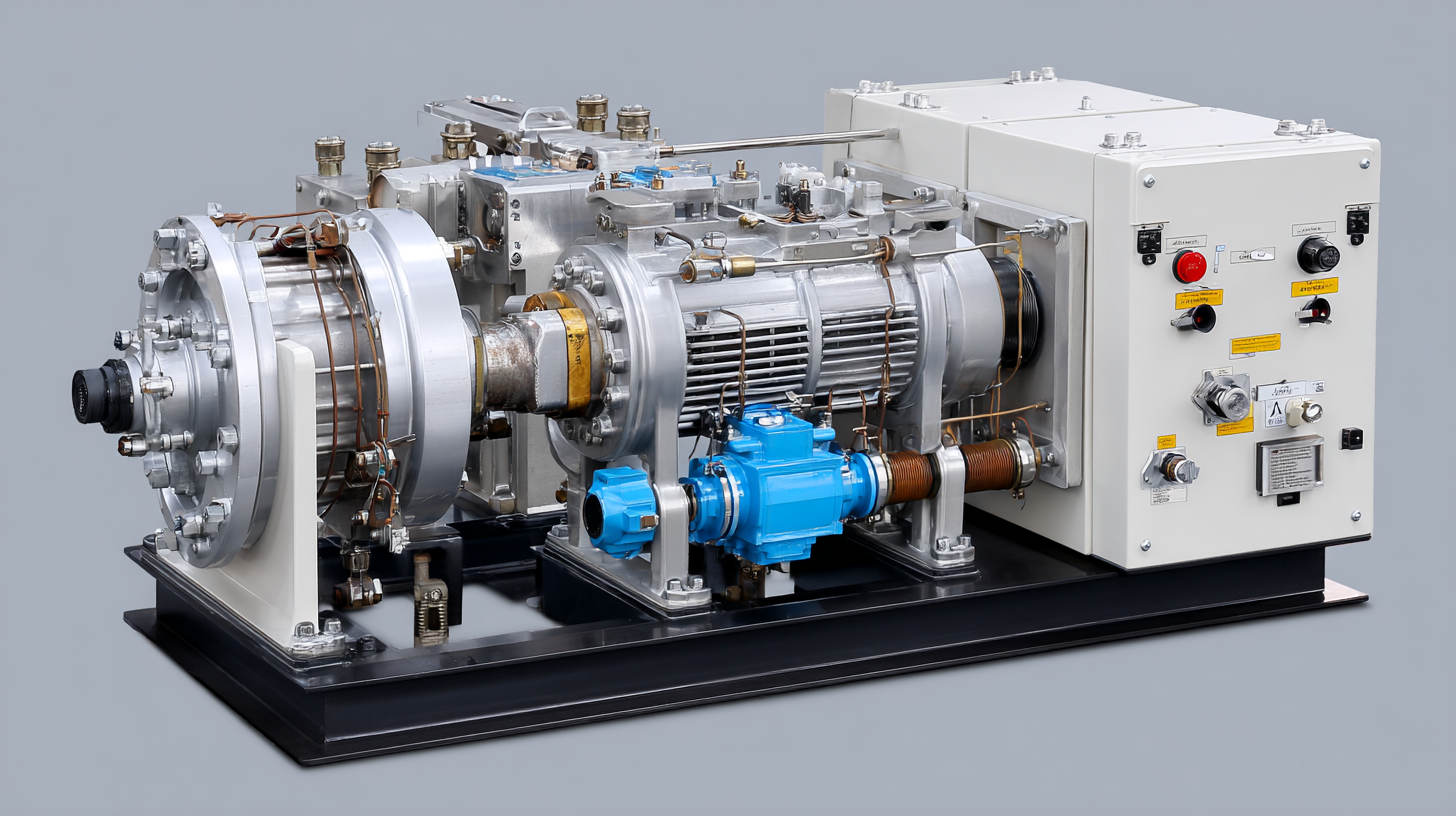

The increasing demand for energy-efficient solutions is driving the adoption of permanent magnet motors in various industries. According to industry reports, the global energy efficient motor market, valued at approximately USD 48.52 billion in 2025, is set to achieve substantial growth, with projections suggesting significant revenue increases thereafter. This surge can be attributed to the rising emphasis on sustainability and operational efficiency among manufacturers.

In India, the shift towards energy-efficient motors is gaining momentum, with numerous companies ramping up their production capabilities. The adoption of these advanced technologies is not only helping industries reduce operational costs but is also aligning with global energy-saving initiatives. Reports indicate that sectors such as manufacturing and transportation are at the forefront of this transformation, implementing permanent magnet motors to enhance their overall energy efficiency and reduce carbon footprints, thereby contributing positively to environmental goals.

Unlocking the Future: Energy Efficiency Benefits of Permanent Magnet Motors

This chart illustrates the energy efficiency improvements achieved by implementing Permanent Magnet Motors across various key industries. As demonstrated, sectors such as Renewable Energy and HVAC experience significant enhancements, contributing to overall sustainability and energy savings.

Technical Advancements in Permanent Magnet Motor Design and Their Efficiency Gains

The advancements in permanent magnet motor design have led to significant efficiencies within various industrial applications. These motors, utilizing high-energy magnets, offer impressive performance benchmarks compared to traditional motors. According to a report by the Department of Energy, implementing advanced permanent magnet motor technology can lead to energy savings of up to 30%, making them a compelling choice for industries aiming to reduce operational costs while aligning with sustainability goals.

One of the critical innovations in motor design includes improved magnetic materials and optimized rotor configurations. The introduction of rare-earth magnets has enhanced the torque density, enabling smaller and more lightweight motor designs. This not only reduces the energy wasted through heat but also increases overall system reliability. Furthermore, many manufacturers have begun integrating smart technologies that monitor performance metrics, allowing for predictive maintenance and further efficiencies.

Tip: When selecting a permanent magnet motor for your application, consider the efficiency ratings and look for designs incorporating the latest magnetic materials and smart technologies. This will ensure you maximize both performance and energy savings over the operational lifespan of the motor. Additionally, evaluate how these motors can be integrated into existing systems to leverage their full potential.

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

| Motor Type | Rated Power (kW) | Efficiency (%) | Weight (kg) | Cooling Type |

|---|---|---|---|---|

| Synchronous Motor | 15 | 94 | 45 | Air-cooled |

| BLDC Motor | 5 | 90 | 25 | Liquid-cooled |

| PM AC Motor | 30 | 95 | 60 | Air-cooled |

| Switched Reluctance Motor | 10 | 88 | 35 | Air-cooled |

Case Studies: Real-World Applications of Imperial Electric Motors Reducing Energy Costs

Imperial Electric permanent magnet motors are leading the charge in enhancing energy efficiency across various industries. A compelling case study can be found in the manufacturing sector, where a prominent automotive parts manufacturer implemented Imperial Electric motors in their assembly lines. By replacing traditional induction motors with these advanced permanent magnet alternatives, the company achieved a remarkable 30% reduction in energy consumption. The motors' high efficiency resulted in lower operational costs and a significant decrease in the plant’s carbon footprint, showcasing a commitment to sustainability.

Another notable application is in the food processing industry. A large dairy processing facility integrated Imperial Electric motors into their conveyor systems and pasteurization units. This transition not only improved the energy efficiency of the equipment but also streamlined operations, allowing for higher production rates with less energy input. The facility reported annual savings of over $50,000 in energy costs, demonstrating how embracing innovative motor technology can yield substantial financial and environmental benefits. These real-world applications illustrate the tangible impact of Imperial Electric motors in optimizing energy use across diverse sectors.