Unlocking Efficiency: How IPM SynRM Motors Revolutionize Modern Industrial Applications

In an era where operational efficiency and sustainability are paramount, the adoption of advanced technologies is essential for modern industrial applications. The IPM SynRM motor (Interior Permanent Magnet Synchronous Reluctance Motor) emerges as a game-changer in this landscape, offering unparalleled energy savings and performance enhancements. According to a report by the International Energy Agency, electric motors account for nearly 45% of the global electricity consumption in industrial applications, highlighting the critical need for innovative solutions like the IPM SynRM motor, which can achieve efficiency levels exceeding 95%. By integrating advanced materials and smart control algorithms, these motors not only optimize energy usage but also reduce operational costs, making them an attractive choice for industries aiming to remain competitive in a rapidly evolving market. As manufacturers seek to modernize their operations, the implementation of IPM SynRM motors represents a significant step towards the realization of more efficient, responsive, and sustainable production processes.

The Evolution of Motor Technology: From Traditional to IPM SynRM Solutions

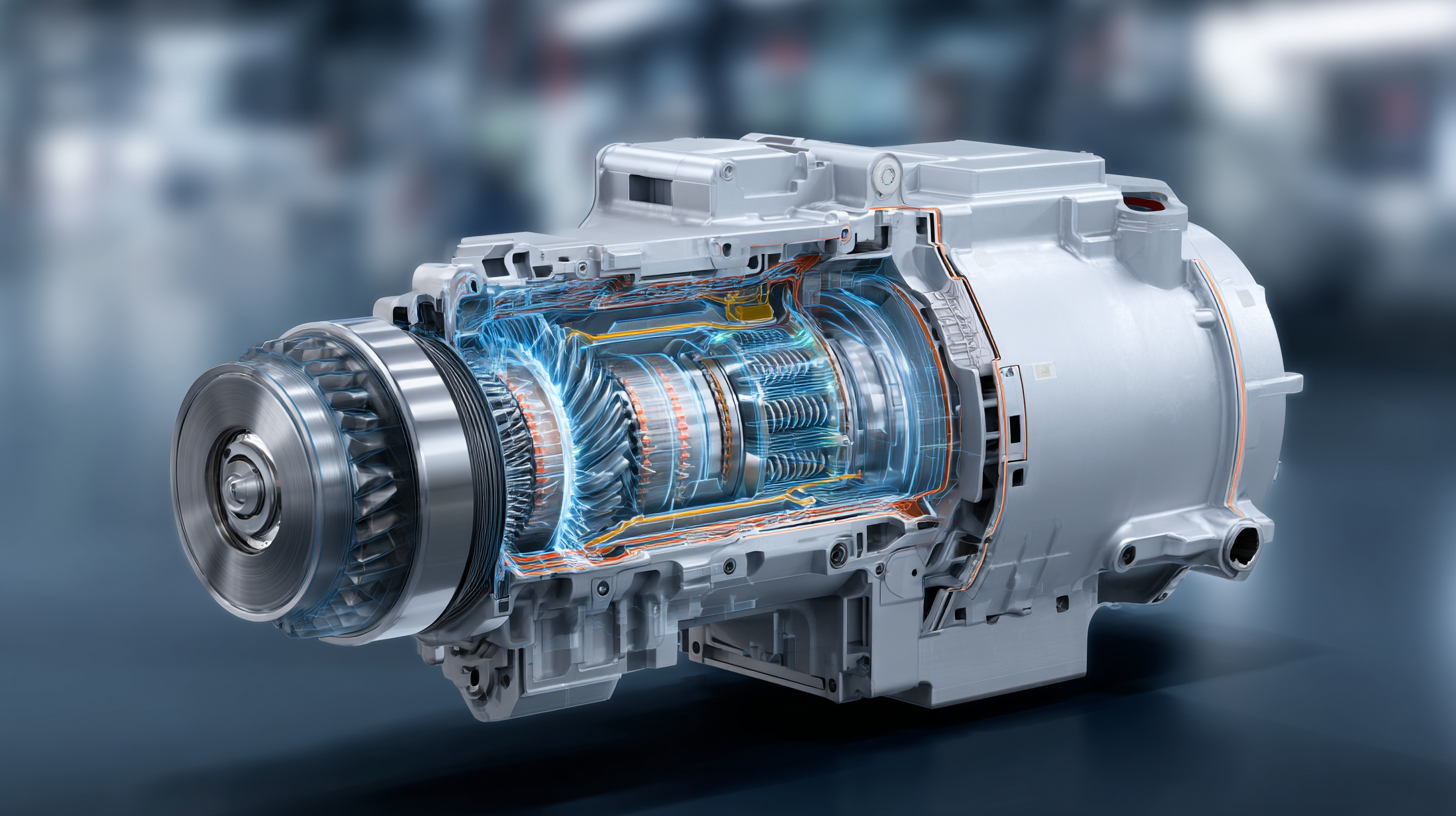

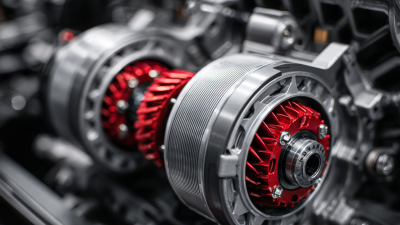

The landscape of motor technology has evolved significantly, moving from traditional motors to advanced Integrated Permanent Magnet Synchronous Reluctance Motors (IPM SynRMs).

IPM SynRM motors are at the forefront of this revolution, offering increases in efficiency and performance for various industrial applications. Their ability to minimize energy losses while providing high torque and improved speed control makes them an excellent choice for modern industrial needs, particularly as companies seek to adopt more sustainable practices.

Tips: When considering an upgrade to IPM SynRM technology, it's important to evaluate the specific application requirements and compatibility with existing systems. Conducting a thorough cost-benefit analysis can highlight the long-term savings associated with energy-efficient motors.

Additionally, innovation in motor technology aligns with global trends towards electrification and sustainability. The shift from conventional motors towards IPM SynRM solutions reflects a broader push within industries to optimize both performance and energy use. Engaging with providers who prioritize research and development can help ensure that businesses remain at the cutting edge of technology.

Key Advantages of IPM SynRM Motors in Industrial Settings

The rise of Interior Permanent Magnet Synchronous Reluctance Motors (IPM SynRM) is changing the game in modern industrial applications due to their unique advantages. Unlike traditional Permanent Magnet Synchronous Motors (PMSMs) or AC Induction Motors (ACIMs), IPM SynRM motors offer improved efficiency and flexibility, making them increasingly applicable across various sectors. A 2023 report from a leading industry analyst highlighted that IPM SynRM motors can achieve up to 10% higher efficiency compared to their counterparts, leading to significant energy savings in large-scale operations.

One key advantage is the enhanced thermal performance and reduced overheating risk, allowing these motors to operate at optimal performance levels for prolonged periods. Additionally, their ability to handle variable loads more effectively makes them ideal for industrial environments that demand versatility. According to recent findings, industries utilizing IPM SynRM technology have reported productivity increases of as much as 15%, proving that this innovation not only enhances operational efficiency but also contributes to a more sustainable manufacturing footprint.

Enhancing Energy Efficiency with IPM SynRM Motors

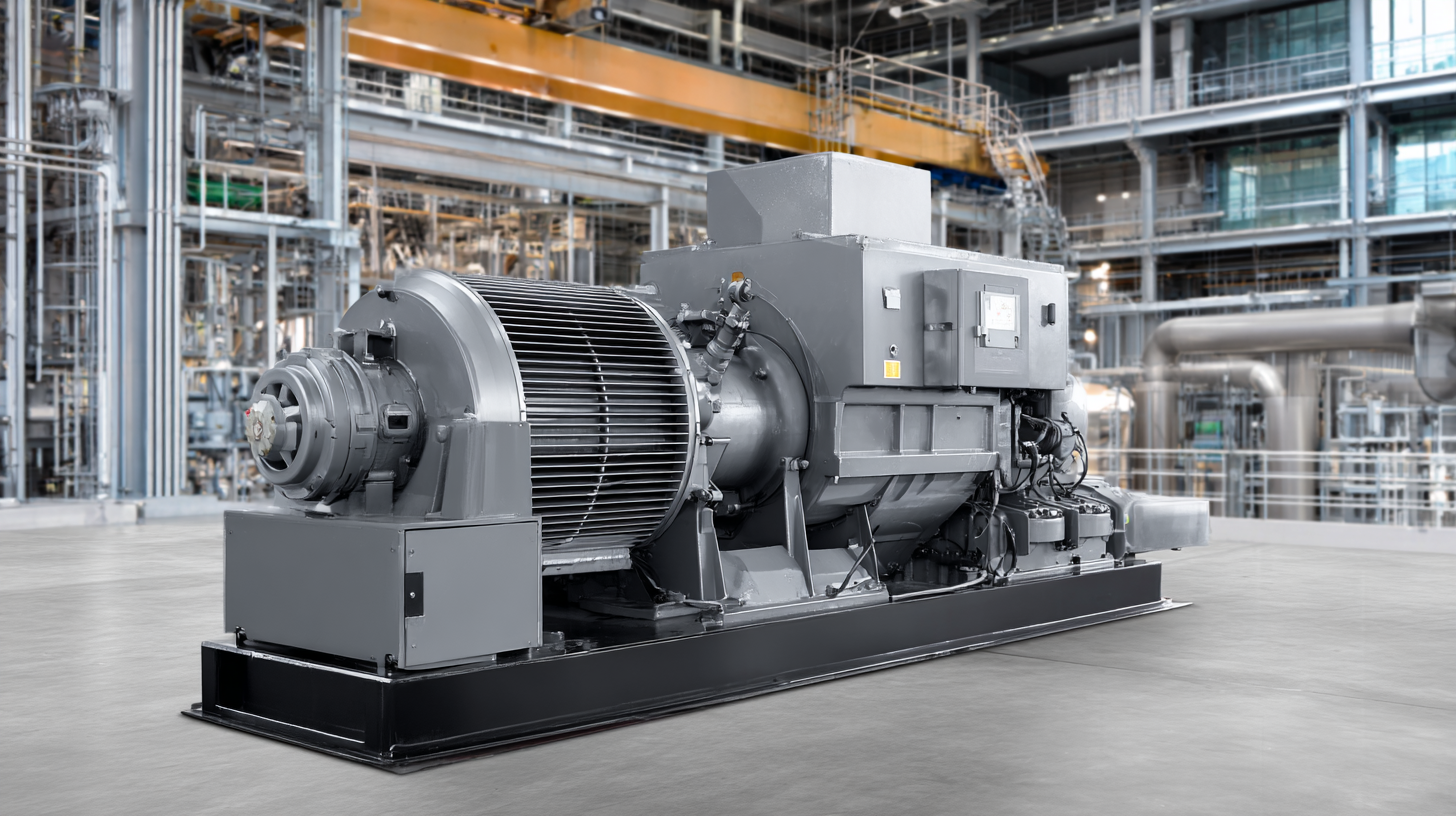

The demand for energy-efficient solutions in industrial applications has never been greater. According to a report by the International Energy Agency (IEA), electric motors account for nearly 45% of global electricity consumption, underscoring the urgent need for advancements in motor technology. Interior Permanent Magnet Synchronous Reluctance Motors (IPM SynRM) are at the forefront of this evolution, offering a remarkable balance between performance and energy efficiency. A study by the Electric Power Research Institute (EPRI) indicates that these motors can achieve efficiency levels exceeding 95%, representing a significant improvement over traditional induction motors.

Implementing IPM SynRM motors not only enhances energy efficiency but also contributes to reduced operational costs. An analysis from the U.S. Department of Energy suggests that upgrading to high-efficiency motors can save industrial facilities between $120 million and $600 million annually in energy costs. Moreover, these motors are designed for optimal performance in variable load conditions, making them ideal for applications in manufacturing and processing industries.

Tips for enhancing energy efficiency with IPM SynRM motors include:

- Regular maintenance checks to ensure optimal performance.

- Investing in smart control systems that can dynamically adjust motor operations based on real-time demand.

- Collaborating with motor manufacturers to access advanced technologies that further maximize energy savings while maintaining output quality.

Real-World Applications of IPM SynRM Motors in Diverse Industries

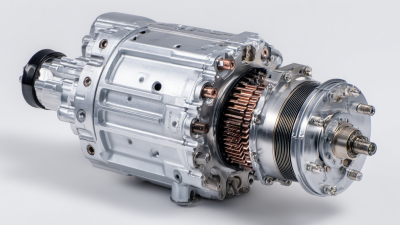

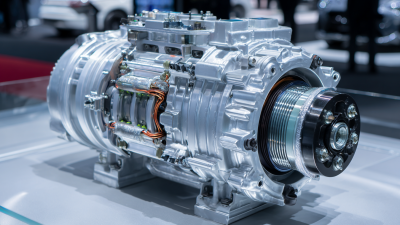

IPM SynRM (Interior Permanent Magnet Synchronous Reluctance Motor) technology is making significant inroads into various industrial sectors, offering unparalleled efficiency and performance. In the automotive industry, for instance, these motors are increasingly used in electric vehicles, where they provide high torque density and energy efficiency, contributing to longer driving ranges and reduced emissions. Their compact design and lightweight nature make them ideal for applications where space and weight are critical factors.

In manufacturing, IPM SynRM motors are becoming the preferred choice for various automation systems. Their precise control capabilities enhance the performance of robotic arms and conveyor systems, resulting in smoother operations and increased productivity. Industries such as textiles and food processing benefit from their ability to maintain consistent speeds and torque, which is essential for high-quality output. Overall, the versatility and advanced performance of IPM SynRM motors are transforming how industries approach energy consumption and operational efficiency.

Unlocking Efficiency: Real-World Applications of IPM SynRM Motors in Diverse Industries

Future Trends: The Role of IPM SynRM Motors in Smart Manufacturing

As industries strive for greater efficiency and sustainability, the integration of Interior Permanent Magnet Synchronous Reluctance Motors (IPM SynRM) is becoming increasingly vital in smart manufacturing. These advanced motors are not only designed for high performance but also for energy efficiency, making them perfect for the evolving landscape of industrial applications. Their ability to deliver precise control and reduced energy consumption directly contributes to the sustainability goals of modern factories, enabling them to not only cut costs but also minimize their environmental impact.

In tandem with the rise of IPM SynRM motors, the trend towards increased automation in manufacturing is on the rise. The integration of robotics within production processes is set to revolutionize how work is organized, ultimately enhancing productivity. This shift not only promises to bring manufacturing jobs back to developed countries but also aligns with the growing emphasis on smart technologies. As industries adopt more intelligent systems, IPM SynRM motors will play a crucial role in powering these advancements, ensuring that smart manufacturing becomes not just a vision for the future but a reality today.

Related Posts

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

-

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

-

Revolutionizing Robotics: The Essential Role of DC Motor Magnets in Modern Technology

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology