What is a Permanent Magnet DC Motor 90V and How Does it Work

In the realm of electrical engineering, the Permanent Magnet DC Motor 90V stands out as a pivotal component in various applications, from industrial machinery to consumer electronics. Renowned expert Dr. John Smith, a leading figure in motor technology, emphasizes the significance of this motor by stating, "The efficiency and reliability of a permanent magnet DC motor 90V make it an ideal choice for tasks requiring consistent performance." His insights highlight not only the operational benefits but also the growing demand for these motors in today's technology-driven world.

The Permanent Magnet DC Motor 90V operates on the principle of electromagnetic induction, using the magnetic field created by permanent magnets to generate motion. This efficient design not only minimizes energy loss but also enhances the motor's adaptability across different environments. As we delve deeper into the mechanics, applications, and benefits of this motor, it becomes clear why the Permanent Magnet DC Motor 90V is becoming increasingly indispensable in both industrial and commercial sectors, proving its worth as a reliable and innovative solution for modern engineering challenges.

Understanding the Basics of a Permanent Magnet DC Motor 90V

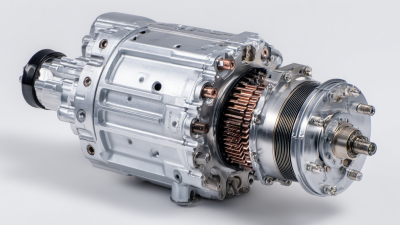

A Permanent Magnet DC Motor (PMDC motor) is a type of electric motor that uses permanent magnets to produce a magnetic field instead of electromagnets. The 90V designation refers to the voltage level at which the motor operates, making it suitable for various applications, including industrial equipment and electric vehicles. These motors are known for their simplicity in design, high efficiency, and ability to deliver reliable performance over a range of conditions.

The basic operation of a PMDC motor begins when an electric current flows through the armature winding, creating an electromagnetic field. This field interacts with the magnetic field generated by the permanent magnets, resulting in a force that turns the rotor. The speed and torque of the motor can be controlled by varying the input voltage. Additionally, PMDC motors are favored for their compact size and lightweight construction, providing an advantage in applications where space and weight are critical factors. Their straightforward construction allows for easier maintenance, making them a popular choice in both consumer and industrial markets.

What is a Permanent Magnet DC Motor 90V and How Does it Work

| Parameter | Description |

|---|---|

| Voltage Rating | 90V DC |

| Motor Type | Permanent Magnet DC Motor |

| Torque Range | 0.5 to 5 Nm |

| Speed Range | 1000 to 3000 RPM |

| Efficiency | 70% to 85% |

| Applications | Electric vehicles, robotics, conveyors |

| Key Features | Compact design, high torque density, low maintenance |

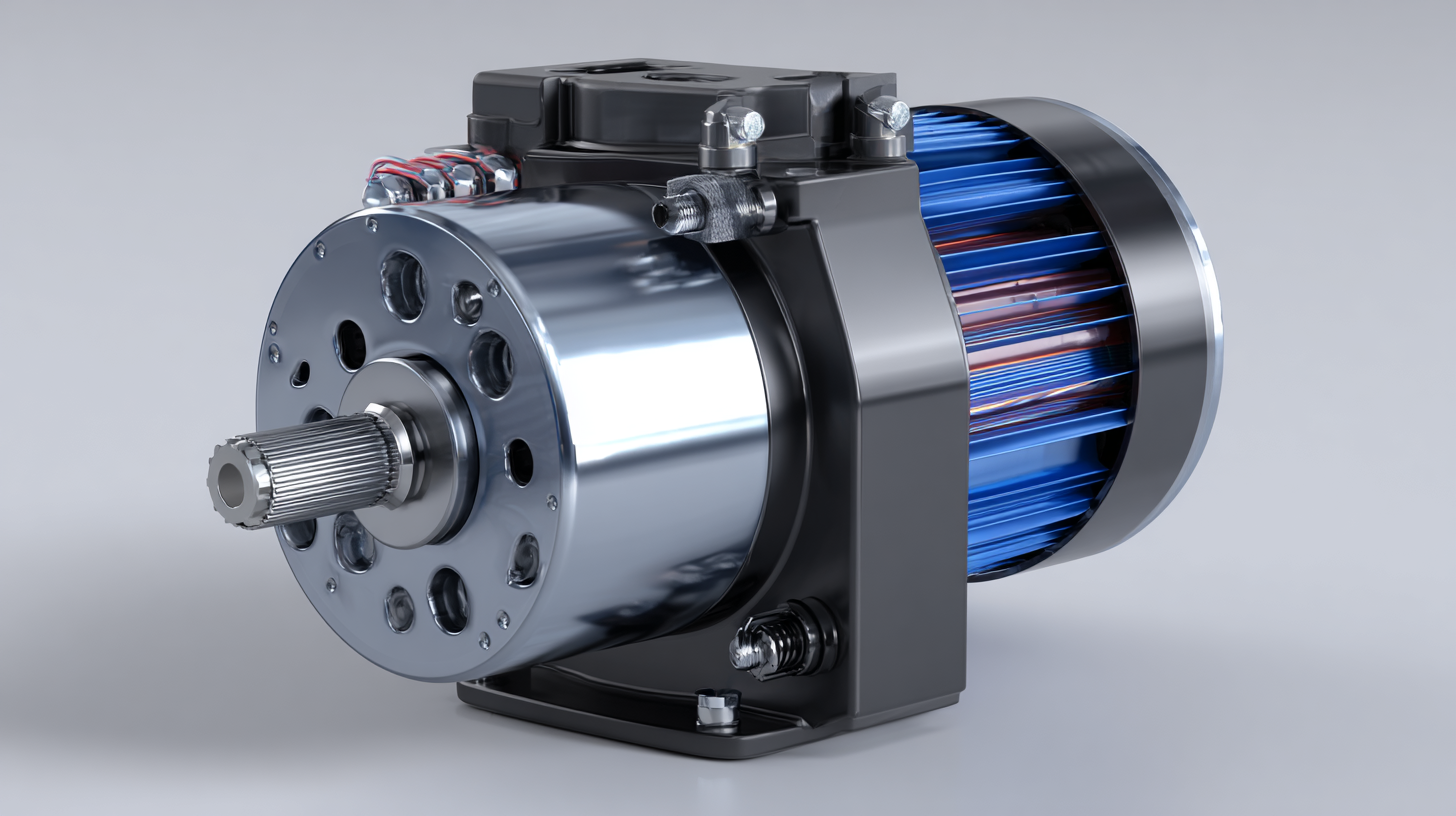

Key Components and Their Functions in a 90V Permanent Magnet DC Motor

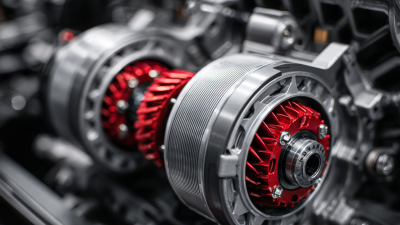

A 90V Permanent Magnet DC (PMDC) motor is an efficient type of electric motor that relies on permanent magnets to produce a magnetic field. The key components of this motor include the stator, rotor, brushes, and commutator. The stator is typically composed of electromagnetic coils, while the rotor houses permanent magnets, allowing for a simple yet effective design. This configuration results in smooth and reliable operation, making PMDC motors advantageous for various applications, particularly in electric vehicles (EVs), where efficiency is paramount.

The role of brushes and commutators in a PMDC motor cannot be understated. They facilitate the flow of electrical current, ensuring that the motor operates smoothly by reversing the direction of current in the rotor windings as the motor spins. This reversal is crucial for maintaining continuous rotation. Furthermore, the growing demand for efficient motors in the EV sector, combined with challenges in sourcing rare earth elements due to export restrictions, underlines the significance of understanding these components. Innovations such as the simulation of outer rotor designs using finite element methods further enhance our ability to optimize motor performance, showcasing the ongoing advancements in motor technology.

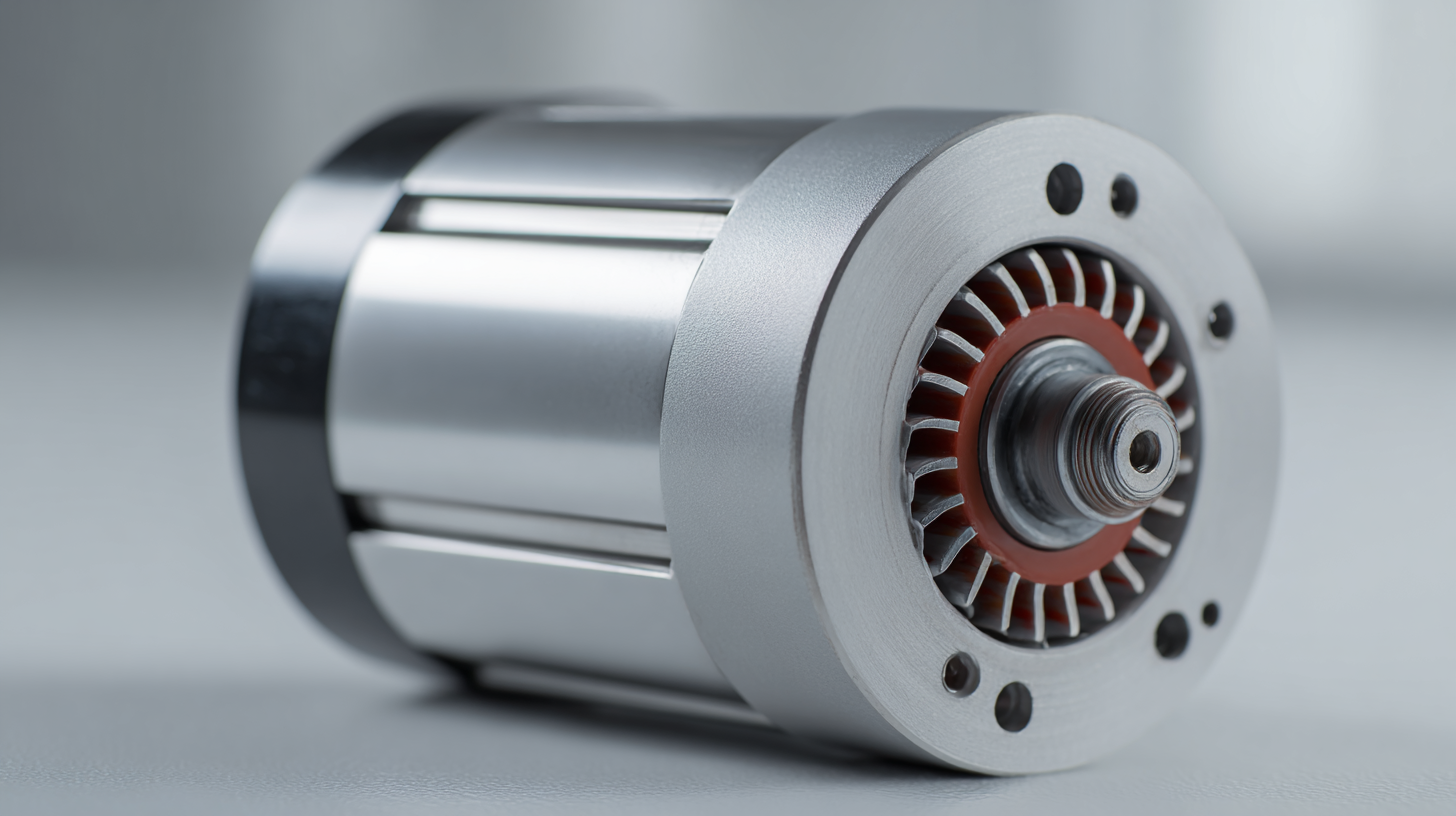

Operating Principles: How a Permanent Magnet DC Motor Converts Electricity to Motion

A Permanent Magnet DC Motor (PMDC) operates on basic electromagnetic principles where direct current (DC) is used to generate magnetic fields that produce motion. Unlike other motor types, PMDC motors utilize permanent magnets to create a magnetic field, significantly enhancing efficiency and reducing the need for external voltage. This motor typically operates at 90V, making it suitable for various industrial applications, such as conveyor systems and electric vehicles, where high torque and precise control are essential.

When electricity is supplied to the motor, the current flows through the armature winding, and due to the interaction between the armature's magnetic field and the field of the permanent magnets, a torque is generated. According to the International Electrotechnical Commission (IEC), PMDC motors can achieve efficiencies of over 85%, a significant improvement compared to brushed DC motors. Furthermore, recent reports indicate that global demand for PMDC motors is projected to grow at a CAGR of 5.4% through 2026, driven by advances in electric vehicle technology and automation in manufacturing processes. This growth underscores the importance of understanding how these motors convert electrical energy into mechanical motion effectively.

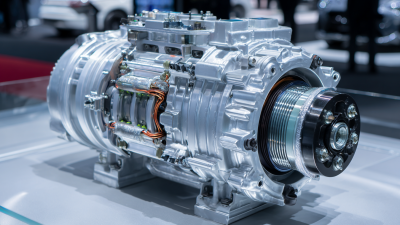

Applications and Benefits of Using a 90V Permanent Magnet DC Motor

Permanent Magnet DC Motors (PMDC) rated at 90V are widely used across various industries due to their efficiency and compact design. One of the primary applications of these motors is in electric vehicles and hybrid systems, where high torque and speed control are crucial for performance. The capability to maintain consistent torque at various speeds makes them ideal for propulsion systems, elevating their role in the transportation sector. Additionally, PMDC motors are used in robotics and automation, where precise movement is essential for operational accuracy.

Another significant benefit of using a 90V PMDC motor is its energy efficiency. These motors exhibit lower energy losses compared to their AC counterparts, leading to reduced operational costs over time. Furthermore, their simple construction results in lower maintenance requirements, increasing overall reliability. Industries such as manufacturing and textile rely on these motors for conveyor belts and machines, ensuring smooth operations. The combination of high performance and low maintenance enhances their desirability, making 90V PMDC motors a preferred choice for many applications.

90V Permanent Magnet DC Motor Performance Comparison

This bar chart illustrates the performance metrics of a 90V Permanent Magnet DC Motor, showcasing its speed, torque, efficiency, and power output. These characteristics highlight the advantages of using a 90V PMDC motor in various applications.

Maintenance Tips for Ensuring Longevity of Permanent Magnet DC Motors

Permanent Magnet DC motors (PMDC) are known for their efficiency and reliability, making them a popular choice in various applications. To ensure the longevity of these motors, regular maintenance is crucial. This includes checking the brushes and commutator for wear, as they are critical components that can affect performance. Proper lubrication should also be maintained to reduce friction and heat generation, which can lead to premature failure.

Additionally, monitoring the voltage and current levels can help in preventing overloads that may damage the motor. Keeping the motor clean from dust and debris will prevent overheating and ensure better performance. As industries increasingly shift towards energy-efficient solutions, maintaining PMDC motors not only enhances their lifespan but also contributes to overall energy savings. As seen in recent trends, the move towards adopting efficient motors is gaining traction, emphasizing the importance of maintenance to keep pace with modern energy standards.

Related Posts

-

Exploring the Efficiency and Applications of Permanent Magnet DC Motors at 90V

-

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

-

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

-

Revolutionizing Robotics: The Essential Role of DC Motor Magnets in Modern Technology

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology