What is a Permanent Magnet DC Motor and How Does it Work

In the world of electrical machinery, the permanent magnet DC motor stands out for its simplicity and efficiency. According to Dr. Sarah Thompson, a leading expert in electric motor technology, "The permanent magnet DC motor combines high performance with compact design, making it ideal for a wide range of applications." This type of motor utilizes the magnetic fields produced by permanent magnets, allowing for a straightforward construction and reliable operation.

The inner workings of a permanent magnet DC motor involve the interaction between the magnetic field from the permanent magnets and the electric current flowing through the motor's windings. As electricity is supplied, the motor converts electrical energy into mechanical energy, making it a vital component in many devices, from small appliances to larger industrial machines. Understanding how this motor operates not only illuminates its significance in engineering but also highlights the growing demand for energy-efficient technologies in today’s market. In this exploration, we will delve into the fundamental mechanics, advantages, and applications of permanent magnet DC motors, showcasing their essential role in modern technology.

Definition and Basic Principles of Permanent Magnet DC Motors

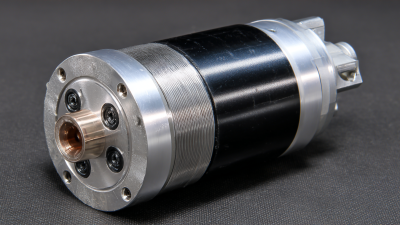

A Permanent Magnet DC (PMDC) motor is an electric motor that uses permanent magnets in its construction to create a magnetic field, as opposed to electromagnetic windings. This motor type consists of a rotor, which rotates within a stator that contains these permanent magnets. When current is supplied to the motor's armature, the interaction between the magnetic field generated by the stator and the magnetic field produced by the armature winding creates a torque, which results in the rotation of the rotor.

The basic principle behind the operation of a PMDC motor revolves around electromagnetism. When the electrical current flows through the motor windings, it generates a magnetic field proportional to the current. This magnetic field interacts with the field of the permanent magnets, causing the rotor to turn in a specific direction. The direction of rotation can be reversed by changing the direction of the current.

PMDC motors are typically known for their simplicity, efficiency, and ease of control, making them ideal for a variety of applications including robotics, automotive systems, and consumer electronics. Their compact design eliminates the need for additional components, reducing complexity and overall maintenance requirements.

Components of a Permanent Magnet DC Motor

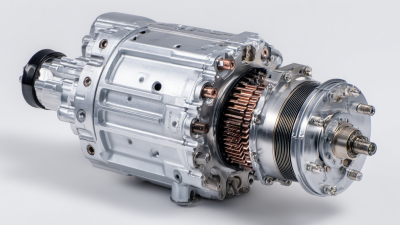

A Permanent Magnet DC (PMDC) motor is a type of motor that utilizes permanent magnets embedded in its rotor to produce a magnetic field. The main components of a PMDC motor include the stator, rotor, commutator, brushes, and winding. The stator houses the permanent magnets, which create a constant magnetic field. This magnetic field interacts with the current-carrying winding located in the rotor.

The rotor is the rotating part of the motor and is equipped with armature windings. When electric current flows through these windings, it generates its own magnetic field. This interaction between the rotor's magnetic field and the magnetic field of the stator causes the rotor to turn. The commutator and brushes play a crucial role in the operation of the motor; they ensure that the current is supplied to the right segments of the rotor as it spins, maintaining the necessary torque and direction of rotation.

In addition to these main components, the structure of a PMDC motor often includes bearings for smooth rotation and a housing that protects the internal parts. The simple design and efficient performance of PMDC motors make them popular in various applications, from household appliances to small automotive systems. Their reliance on permanent magnets allows for a compact design and reduces the need for additional power supplies to create the magnetic field.

Mechanism of Operation in Permanent Magnet DC Motors

Permanent Magnet DC (PMDC) motors are widely recognized for their efficiency and simplicity in operations. The core mechanism of a PMDC motor involves the interaction between a permanent magnet's magnetic field and the electromagnetic field generated by the armature winding. When voltage is applied to the armature, current flows through the windings, creating a magnetic field that interacts with the fixed magnetic field of the permanent magnets. This interaction generates torque, causing the rotor to turn.

The efficiency of PMDC motors is enhanced by their design. According to industry reports, they can achieve efficiencies of 70% to 90% under optimal conditions, depending on the load and operating speed. The absence of field windings simplifies the construction and reduces the overall size and weight compared to traditional DC motors with wound fields. This simplicity leads to lower maintenance requirements and longer operational lifetimes, making them ideal for applications in robotics, automotive systems, and consumer electronics.

Moreover, the precise control over speed and torque in PMDC motors is a significant advantage. The torque output can be controlled by varying the input voltage, while the speed can be modulated through the armature current. This level of control is advantageous in applications requiring variable speed characteristics, and research indicates that PMDC motors exhibit superior performance in dynamic response compared to alternatives, contributing to their increasing adoption in various industries.

Applications of Permanent Magnet DC Motors in Industry

Permanent magnet DC (PMDC) motors are widely utilized in various industries due to their efficient performance and reliability. These motors leverage permanent magnets to produce a magnetic field, allowing for a simplified design without the need for additional electromagnets. According to a report by ResearchAndMarkets, the global permanent magnet motor market is expected to reach approximately $30 billion by 2027, reflecting a CAGR of around 10% from 2020. This growth is largely attributed to the increasing demand for efficient motors in automotive, manufacturing, and robotics applications.

In the industrial sector, PMDC motors serve critical roles in numerous applications. They are commonly employed in conveyor systems, robotics, and automation processes, where precision and reliability are paramount. For instance, in the automotive industry, PMDC motors drive components such as power windows and seats, enhancing functionality while minimizing energy consumption. A report from Grand View Research highlights that sectors like industrial automation are projected to expand significantly, further propelling the adoption of PMDC motors due to their low maintenance and high torque characteristics. As industries continue to strive for greater efficiency and sustainability, PMDC motors are poised to remain a key component in modern engineering solutions.

Advantages and Limitations of Permanent Magnet DC Motors

Permanent Magnet DC (PMDC) motors offer several advantages that make them an attractive choice in various applications. One of the primary benefits is their simplicity in design, which leads to ease of use and installation. PMDC motors are typically smaller and lighter than their counterparts, which makes them ideal for applications where space and weight are critical considerations. Another significant advantage is their efficiency; as they utilize permanent magnets, they can achieve higher torque at lower power consumption, resulting in energy savings and reduced operational costs over time.

However, PMDC motors also come with certain limitations that potential users should consider. One notable drawback is the cost associated with the high-quality permanent magnets required for efficient performance. Additionally, due to the presence of these magnets, PMDC motors can suffer from reduced performance in high-temperature environments, as increased heat may demagnetize the magnets, leading to a decline in efficiency. Furthermore, their speed control is also more challenging compared to other motor types, which can limit their versatility in applications requiring precise speed adjustments.

Overall, while PMDC motors provide significant benefits, understanding these limitations is crucial for effective application and operation.

Related Posts

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

2025 Top 5 Permanent Magnet DC Motor 180V Options for Enhanced Performance

-

Top 7 Benefits of Using Permanent Magnet DC Motors in Modern Applications

-

Why IPM SYNRM Motors Are Revolutionizing Energy Efficiency in Modern Applications

-

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

-

Top 5 Benefits of Neodymium Magnet Motors You Need to Know