10 Tips for Understanding Direct Current Permanent Magnet Motors

Understanding direct current permanent magnet motors is essential for engineers and enthusiasts alike, as these motors play a crucial role in various applications from industrial machinery to electric vehicles. With their ability to provide high efficiency and precise control, direct current permanent magnet motors have become increasingly popular in modern technological solutions. However, navigating the intricacies of their design and operation can be challenging for those new to the field.

This article offers ten tips to enhance your understanding of direct current permanent magnet motors, covering fundamental principles, specifications, and applications. By breaking down complex concepts into easily digestible information, we aim to equip readers with the knowledge needed to effectively engage with these sophisticated machines. Whether you are designing a new system or troubleshooting existing motors, these insights will ensure a solid foundation in understanding direct current permanent magnet motors and their functionalities.

Understanding the Basics of Direct Current Permanent Magnet Motors

Direct current (DC) permanent magnet motors are widely used in various applications due to their simplicity and efficiency. At the core of these motors is the principle of electromagnetism, where the interaction between a permanent magnet and an electric current generates motion. Understanding the basics involves grasping the components, such as the rotor, stator, and commutation system that facilitate the conversion of electrical energy into mechanical energy. The permanent magnets, typically made from rare earth materials, provide a stable magnetic field, which enhances the motor's performance and responsiveness.

Another essential aspect is the operational characteristics of DC permanent magnet motors. These motors offer excellent speed control and torque performance, making them ideal for applications requiring precise motion. The absence of brushes in some designs leads to reduced wear and maintenance needs, further enhancing their appeal. Factors such as load conditions, temperature, and supply voltage significantly influence the motor's efficiency and longevity.

As one delves deeper into the mechanics of these motors, it becomes evident how their design impacts their functionality, paving the way for innovation in motor applications from robotics to electric vehicles.

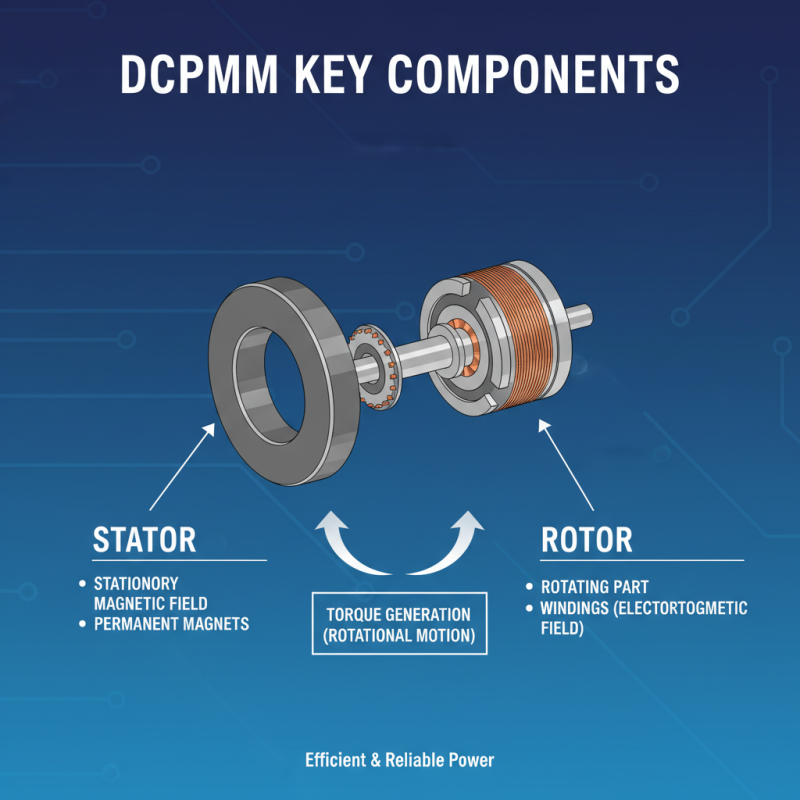

Key Components of Direct Current Permanent Magnet Motors Explained

Direct Current Permanent Magnet Motors (DCPMMs) are characterized by key components that play essential roles in their operation and efficiency. At the heart of the motor is the stator, which provides a stationary magnetic field, typically created by permanent magnets. These magnets are strategically positioned to create a consistent magnetic flux that interacts with the rotor. The rotor, which is the rotating part of the motor, is designed with windings that carry current, generating an electromagnetic field. This interaction between the stator's magnetic field and the rotor's electromagnetic field is what produces the rotational motion essential for motor function.

Another critical component is the commutation system, which is responsible for reversing the direction of current in the rotor windings as the motor operates. This is vital for maintaining continuous motion and optimizing torque output. Modern DCPMMs often use electronic controllers for more efficient commutation, enhancing performance while reducing mechanical wear. Additionally, the efficiency of these motors is influenced by their design elements, such as winding configuration and the materials used for the rotor and stator. Understanding these components and their interactions provides a deeper insight into the efficiency and application of direct current permanent magnet motors in various industries.

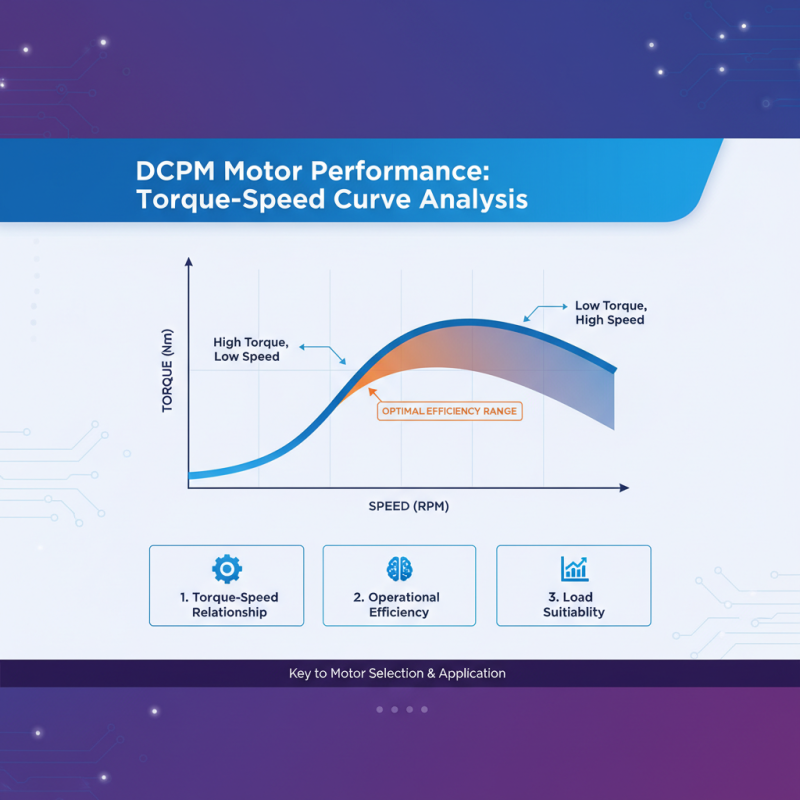

How to Analyze the Performance Characteristics of These Motors

When analyzing the performance characteristics of Direct Current Permanent Magnet (DCPM) motors, several key factors must be taken into account. First and foremost, understanding the torque-speed curve is crucial. This curve illustrates how the torque produced by the motor varies with the speed, helping to identify the operational efficiency and suitability of the motor for specific applications. By examining this relationship, one can determine the optimal speed range for maximum efficiency, as well as predict how the motor will perform under varying load conditions.

Another important aspect to consider is the efficiency of the motor, which is influenced by both electrical and mechanical losses. Factors such as winding resistance, stray losses, and core losses significantly impact the overall efficiency of the DCPM motor. Analyzing these losses helps in quantifying energy consumption and operational costs. Additionally, thermal performance plays a vital role in assessing the longevity and reliability of the motor. Monitoring temperature rise during operation ensures that the motor remains within safe operational limits, which is essential for maintaining performance and preventing premature failure. Overall, these analysis techniques equip users with a comprehensive understanding of DCPM motors, enabling more informed decisions in their application.

Practical Applications of Direct Current Permanent Magnet Motors in Industry

Direct Current (DC) Permanent Magnet Motors (PMMs) have become increasingly essential in various industrial applications due to their efficiency and reliability. According to a recent industry report by Research and Markets, the global market for DC motors is expected to reach USD 13.89 billion by 2025, growing at a CAGR of 6.67% from 2020. This growth is largely driven by the surging demand for energy-efficient solutions in the manufacturing sector, as PMMs can provide significant reductions in energy consumption compared to traditional motor types.

In manufacturing, DC PMMs are frequently applied in automation systems, powering conveyor belts, pumps, and robotics. Their ability to provide precise control over speed and torque makes them ideal for tasks that require high precision, such as in CNC machinery and automated assembly lines. Furthermore, their compact size and reduced maintenance needs, attributed to fewer moving parts, allow for seamless integration into existing systems. The shift towards smart manufacturing techniques has further propelled the adoption of DC PMMs, as they can easily be integrated with modern control systems for enhanced performance monitoring and energy management. As industries continue to prioritize efficiency and sustainability, DC PMMs are set to play a crucial role in the evolution of industrial processes.

10 Tips for Understanding Direct Current Permanent Magnet Motors

| Tip | Description | Application |

|---|---|---|

| 1 | Understand the basics of motor construction. | Used in small appliances for efficient operation. |

| 2 | Learn how to calculate torque and speed. | Applied in robotics for precise movement control. |

| 3 | Familiarize with commutation and its importance. | Used in electric vehicles for efficient energy use. |

| 4 | Explore the operation of brushes and bearings. | Implemented in conveyor systems for smooth operation. |

| 5 | Understand the role of the power supply. | Used in automated manufacturing for consistent power flow. |

| 6 | Learn how to control speed with varying voltage. | Applied in fans and blowers for temperature control. |

| 7 | Recognize the advantages of using permanent magnets. | Implemented in portable tools for improved efficiency. |

| 8 | Investigate thermal management techniques. | Used in aerospace applications for reliability under stress. |

| 9 | Study common fault diagnosis and maintenance. | Implemented in HVAC systems for effective maintenance. |

| 10 | Keep updated with industry trends and technologies. | Applied in smart home technologies for improved automation. |

Tips for Maintenance and Troubleshooting of Permanent Magnet Motors

When it comes to maintaining Direct Current Permanent Magnet Motors, regular inspection and cleaning are essential for optimal performance. Dust and debris can accumulate within the motor, potentially leading to overheating or decreased efficiency. It is advisable to periodically clean the exterior and ensure that ventilation paths are clear. Additionally, inspecting the motor's mounting and connection points can prevent vibrations and disconnections, improving longevity.

Troubleshooting issues with permanent magnet motors often begins with checking the electrical supply. Ensuring that voltage and current levels are within specifications can help identify potential problems before they escalate. If the motor fails to start or operates irregularly, examining the brushes and commutator for wear is important, as these components often contribute to performance issues. Utilizing diagnostic tools to monitor motor behavior can provide insights into anomalies, allowing for timely interventions and repairs. Regular maintenance routines combined with effective troubleshooting can significantly enhance the reliability and lifespan of permanent magnet motors.

Understanding Direct Current Permanent Magnet Motors

This chart displays the performance metrics of Direct Current Permanent Magnet Motors, highlighting key factors such as efficiency, torque, speed, heat generation, and noise level.

Related Posts

-

Top 7 Benefits of Using Permanent Magnet DC Motors in Modern Applications

-

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

-

Top 10 Benefits of Using a Permanent Magnet DC Motor 90V for Your Projects

-

Top 10 Benefits of Using a 90V Permanent Magnet DC Motor for Your Projects

-

Top 10 Benefits of Using Permanent Magnet Motors in Modern Applications

-

Top 10 Tips for Choosing a Permanent Magnet DC Motor 180V for Your Project