2025 Top 5 Permanent Magnet DC Motor 180V Options for Enhanced Performance

In the ever-evolving landscape of electric motors, the demand for efficient and high-performance solutions remains a top priority for various industries, including automotive, robotics, and renewable energy. The permanent magnet DC motor 180V has emerged as a significant player in this domain, offering superior torque density and energy efficiency compared to traditional motor designs. According to a 2022 industry report by Research and Markets, the global market for permanent magnet motors is projected to reach $22 billion by 2026, with a compound annual growth rate (CAGR) of approximately 9.2%. This trend highlights the increasing reliance on advanced motor technologies that can enhance performance while minimizing environmental impact.

As we approach 2025, manufacturers are focusing on developing innovative solutions that harness the power of the permanent magnet DC motor 180V. Not only do these motors provide high-performance capabilities, but they also contribute to more compact and lightweight designs, essential for applications where space and weight savings are critical. The integration of advanced materials and intelligent control systems is set to propel the performance of these motors to new heights, addressing the growing need for energy-efficient solutions across diverse applications. This article explores the top five permanent magnet DC motors rated at 180V, emphasizing their features, advantages, and potential impact on the future of motor technology.

2025 Innovations in Permanent Magnet DC Motors for High Voltage Applications

The 2025 market for Permanent Magnet DC (PMDC) motors is witnessing significant innovations, particularly for high-voltage applications. As industries lean towards energy efficiency and reduced operational costs, PMDC motors, known for their compact size and high torque density, are gaining traction. According to a recent industry report, the demand for high-voltage PMDC motors is expected to grow at a CAGR of over 8% from 2023 to 2028, driven by advancements in electric vehicle technology and robotics.

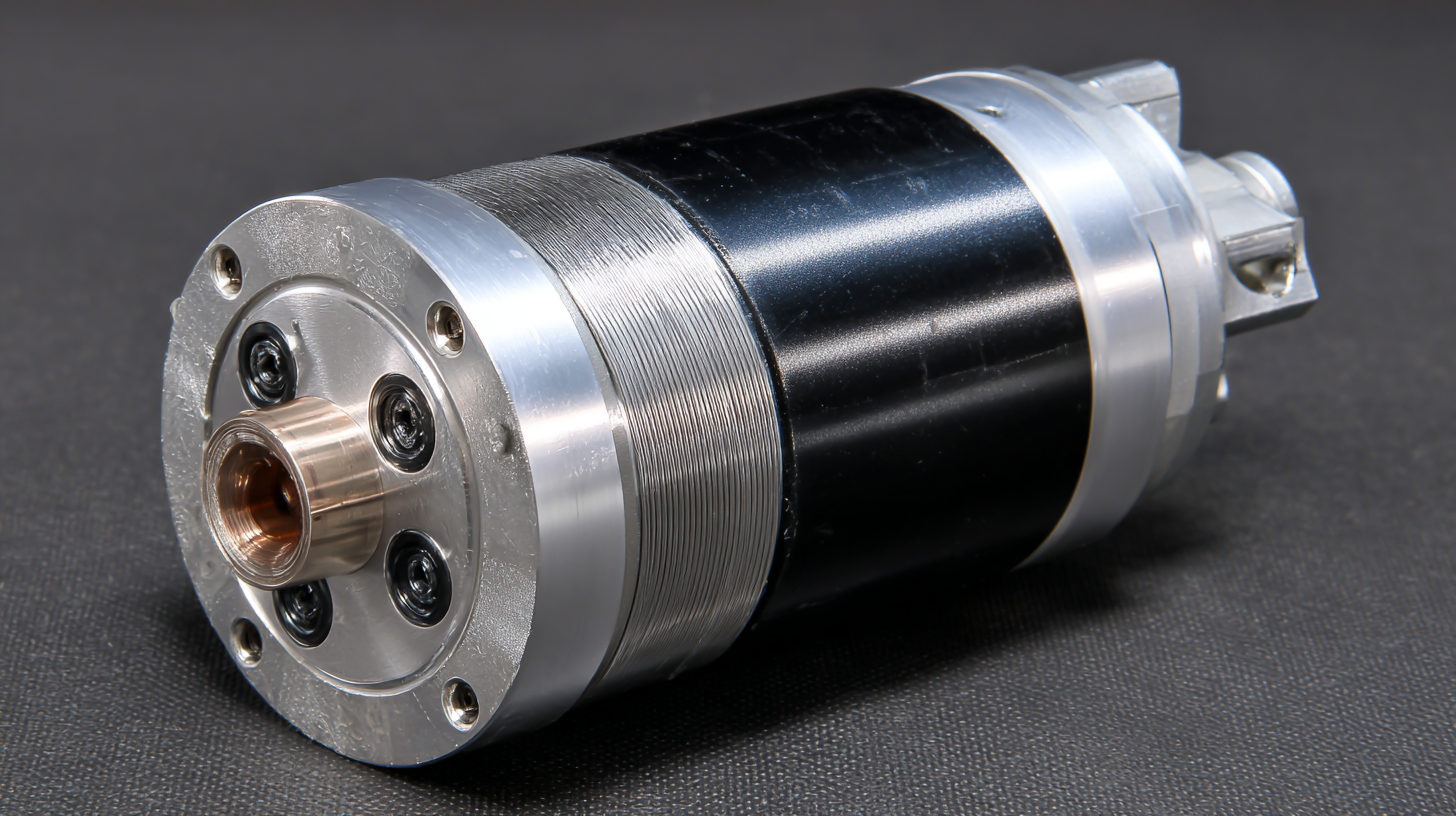

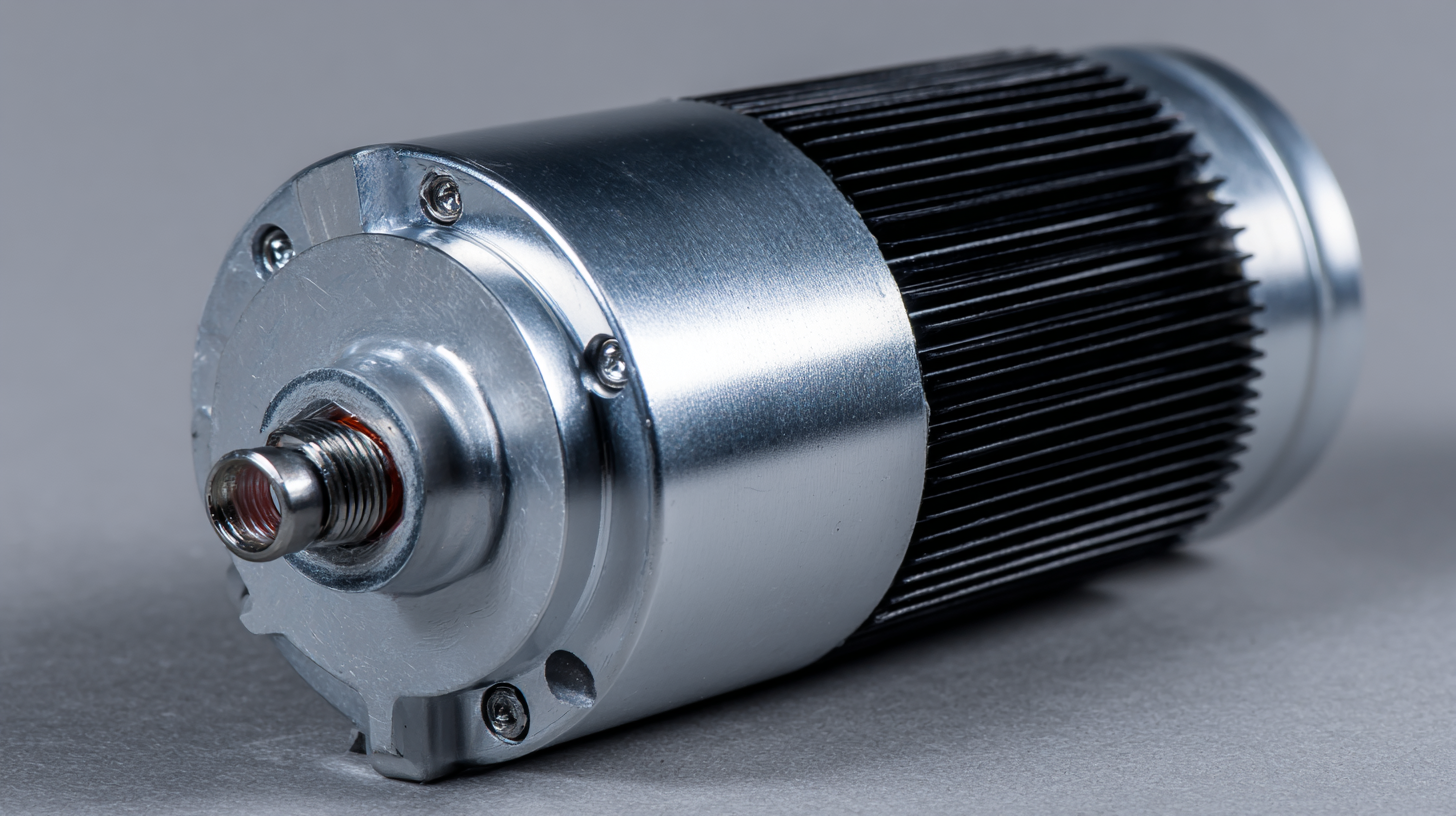

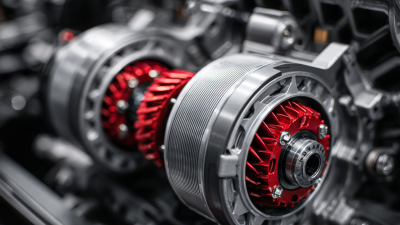

Key developments in permanent magnet technology, including enhancements in material composition and motor designs, are enabling higher performance and reliability. For instance, the integration of rare earth magnets and advanced cooling systems can increase the efficiency of PMDC motors, making them ideal for applications in aerospace and industrial automation. Companies are also exploring innovative configurations such as sensors and IoT connectivity to optimize motor performance further, adapting to the growing trends of smart manufacturing and automation.

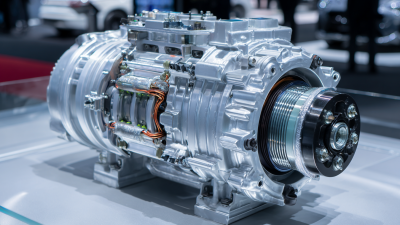

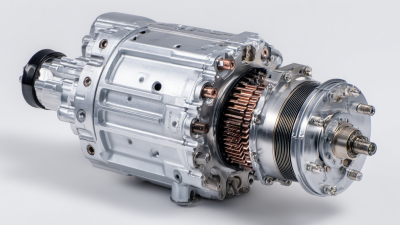

At recent industry events, several leading manufacturers have showcased their next-generation PMDC motors capable of operating at 180V, underlining the evolution of motor designs to meet stringent performance standards. This shift is not only indicative of the growing importance of high voltage applications but also reflects a broader trend towards more sustainable and efficient energy solutions in various sectors.

Key Features to Look for in 180V Permanent Magnet DC Motors

When selecting a 180V Permanent Magnet DC Motor, several key features significantly influence performance and efficiency. First, consider the motor's power-to-weight ratio, which impacts acceleration and overall system responsiveness. A lightweight motor without sacrificing power can enhance application performance, making it ideal for various uses, from robotics to vehicle propulsion.

Another vital aspect to note is the motor's thermal management capabilities. High-performance motors usually incorporate efficient cooling systems that prevent overheating and ensure optimal operation under load. This feature is particularly crucial for motors used in demanding environments or continuous operation scenarios.

**Tips:** Always check the motor's efficiency ratings to ensure it meets your application's power requirements. Additionally, look for motors that offer customizable options, as this can lead to better integration within your system. Finally, review user feedback and performance benchmarks to make an informed choice that aligns with your specific needs.

2025 Top 5 Permanent Magnet DC Motor 180V Performance Comparison

This chart compares the key performance metrics of the top 5 permanent magnet DC motors operating at 180V in terms of efficiency, torque, and weight. The data showcases features important for selecting high-performance motors.

Top 5 Brands Leading the Market in 2025 for Enhanced Motor Performance

In 2025, the landscape of permanent magnet DC motors is being significantly shaped by key brands that prioritize enhanced performance and efficiency. Top manufacturers are increasingly focusing on advanced design and material utilization, leading to motors that deliver not only superior output but also improved energy savings. The global shift towards electric vehicles (EVs) has amplified the demand for such high-performance motors, with electric car sales reportedly surpassing 17 million units worldwide in 2024, marking over 25% growth from the previous year.

Furthermore, industry reports indicate that the European market for electric vehicles has also seen promising trends, with over 20% of new car sales comprising electrified models as of mid-2025. This surge in demand is pushing brands to innovate rapidly, particularly in the realm of smart technology integration. Leading companies are dedicated to refining their motor technologies, ensuring they remain at the forefront of this evolving market, which is characterized by increasing consumer expectations and regulatory pressures aimed at reducing carbon emissions. As these brands continue to lead, their advancements are pivotal in setting benchmarks for performance and sustainability in the electric vehicle segment.

Comparative Analysis of Efficiency in 2025's Best 180V DC Motor Models

In recent years, the efficiency of electric motors has gained significant attention, particularly in the context of comparing brushless DC (BLDC) motors to switched reluctance motors (SRM). As industries seek optimized performance for specific applications, such as off-grid water pumping, the design and analysis methodologies, including finite element method (FEM), have become crucial. These techniques provide insights into the operational efficiency and effectiveness of different motor types, which is essential when considering the best options for enhanced performance.

For the 2025 market, a comparative analysis of the top 180V permanent magnet DC motors focuses on their operational efficiency. As electric vehicles and other applications increasingly rely on these motors, assessing factors like torque output, power consumption, and thermal performance becomes imperative. The ongoing competition among manufacturers continues to drive technological advancements, resulting in a lineup of models that promise improved efficiency and reliability, vital for both consumers and industries striving for sustainability.

Future Trends in Permanent Magnet DC Motor Technology and Market Predictions

The landscape of permanent magnet DC motor technology is poised for significant evolution by 2025, driven by advancements in energy efficiency and performance enhancements. As industries increasingly pivot towards sustainable practices, the demand for high-efficiency motors is projected to escalate, catalyzing innovation in motor design and production. Notably, the global energy-efficient motor market, valued at $48.5 billion in 2022, is expected to surge to $119.1 billion by 2032, reflecting a compound annual growth rate of 9.5%. This trend speaks volumes about the pivotal role of permanent magnet DC motors in electrification, particularly in applications like electric vehicles and renewable energy systems.

Moreover, as the market for electric motors expands, manufacturers will likely gravitate towards advanced materials, such as high-performance ferrite magnets, which are anticipated to gain substantial market share, particularly in North America. The integration of cutting-edge technologies and research efforts focused on optimizing the performance of permanent magnet synchronous generators will further enhance the efficiency of wind energy conversion systems. These factors will not only redefine performance standards in the industry but also shape the future of electric motors across various sectors.

Related Posts

-

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

-

Exploring the Efficiency and Applications of Permanent Magnet DC Motors at 90V

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

-

Unlocking the Future: How Imperial Electric Permanent Magnet Motors Enhance Energy Efficiency

-

Revolutionizing Robotics: The Essential Role of DC Motor Magnets in Modern Technology