Top 10 IPM Motors: Best Options for Efficiency and Performance in 2023

In the ever-evolving landscape of electric motors, the quest for optimal efficiency and performance is paramount. As industries strive to reduce energy consumption and enhance productivity, the adoption of IPM motors has gained remarkable traction. Renowned expert Dr. Emily Carter, a leading authority in motor technology, states, "IPM motors not only offer superior efficiency but also ensure robust performance in demanding applications." This highlights the pivotal role that interior permanent magnet motors play in modern engineering solutions.

As we delve into the top 10 IPM motors for 2023, it becomes clear that these innovations are not merely trends; they represent a fundamental shift towards more sustainable and effective power solutions. From their ability to minimize energy losses to their compact design, IPM motors are revolutionizing the way we approach motor-driven applications. Join us as we explore the best options available in the market today, focusing on their efficiency metrics, performance capabilities, and the technological advancements that set them apart. Discover how these top-rated IPM motors can drive your operations towards greater efficiency in the years ahead.

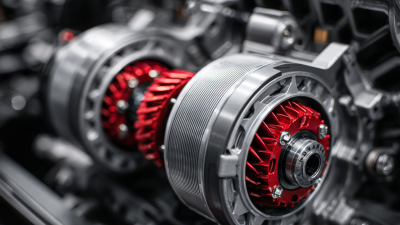

Overview of IPM Motors: Principles and Key Features

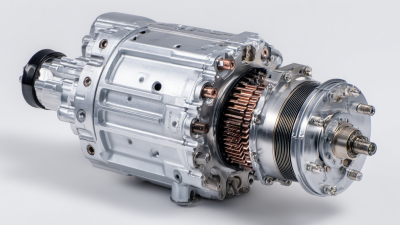

IPM (Interior Permanent Magnet) motors have gained significant attention in recent years due to their remarkable efficiency and performance advantages. These motors utilize permanent magnets embedded within the rotor, allowing for greater torque and improved efficiency at various operational speeds. One of the foundational principles of IPM motors is their ability to minimize energy loss through optimized magnetic designs, making them suitable for applications that require high responsiveness and energy savings.

Key features of IPM motors include their compact size and lightweight design, which enable ease of integration into various systems. Additionally, these motors offer superior thermal management, enhancing their lifespan and reliability. The capability to operate effectively in both high-speed and low-speed conditions further sets IPM motors apart from traditional alternatives, making them ideal for industrial, automotive, and renewable energy applications. Their advancing technology continually drives innovation, resulting in enhanced performance metrics that meet the demanding requirements of modern engineering challenges.

Top 10 IPM Motors: Best Options for Efficiency and Performance in 2023

| Motor Model | Power Rating (kW) | Efficiency (%) | Torque (Nm) | Weight (kg) |

|---|---|---|---|---|

| Model A | 7.5 | 92 | 35 | 25 |

| Model B | 11 | 90 | 50 | 30 |

| Model C | 15 | 95 | 70 | 35 |

| Model D | 18.5 | 93 | 90 | 40 |

| Model E | 22 | 91 | 120 | 45 |

| Model F | 30 | 89 | 200 | 60 |

| Model G | 37 | 94 | 250 | 70 |

| Model H | 45 | 96 | 300 | 80 |

| Model I | 55 | 97 | 400 | 90 |

| Model J | 75 | 95 | 500 | 100 |

Criteria for Selecting the Best IPM Motors in 2023

When selecting the best Interior Permanent Magnet (IPM) motors in 2023, several key criteria must be considered to ensure optimal efficiency and performance. First and foremost, the efficiency rating of the motor is crucial. Look for motors that boast high efficiencies, ideally above 90%, as these can significantly reduce energy consumption, leading to lower operational costs over time. Additionally, evaluating the torque-to-weight ratio is essential, as a higher ratio often translates to better performance in applications requiring rapid acceleration and responsiveness.

Another important aspect is the motor's thermal management capabilities. IPM motors generate heat during operation, and effective cooling systems can enhance their durability and performance. Prospective buyers should also consider the versatility of the motor in terms of its compatibility with various control systems and application needs. Finally, reliability and brand reputation should not be overlooked; manufacturers with a history of producing high-quality, robust motors typically offer better long-term value. By carefully weighing these criteria, one can identify the best IPM motors available in the market for maximum efficiency and performance.

Top 10 High-Efficiency IPM Motors for Industrial Applications

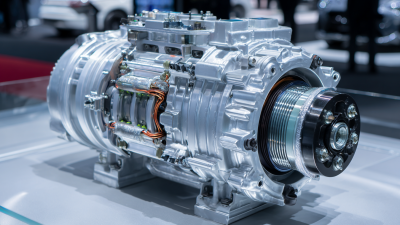

In 2023, the demand for high-efficiency Interior Permanent Magnet (IPM) motors in industrial applications continues to grow, driven by the need for improved energy performance and reduced operational costs. According to a report by the American Council for an Energy-Efficient Economy (ACEEE), the implementation of high-efficiency motors can lead to energy savings between 2-8% over traditional designs. This efficiency is crucial in industries like manufacturing and material handling, where motors account for a significant portion of total energy consumption—estimated to be around 65% in electric motor drive systems.

Recent advancements in IPM technology have also bolstered their appeal. IPM motors are now typically able to achieve efficiency ratings exceeding 95%, supported by the latest developments in magnetic materials and motor design. A study published in the IEEE Transactions on Industrial Electronics highlighted how using IPM motors not only improves energy efficiency but also offers enhanced torque density and performance under variable load conditions. When selecting IPM motors, industries should consider not only energy savings but also their overall impact on productivity and equipment lifespan, ultimately contributing to a more sustainable industrial landscape.

Top 10 High-Efficiency IPM Motors for Industrial Applications in 2023

Performance Comparison: Leading IPM Motors on the Market

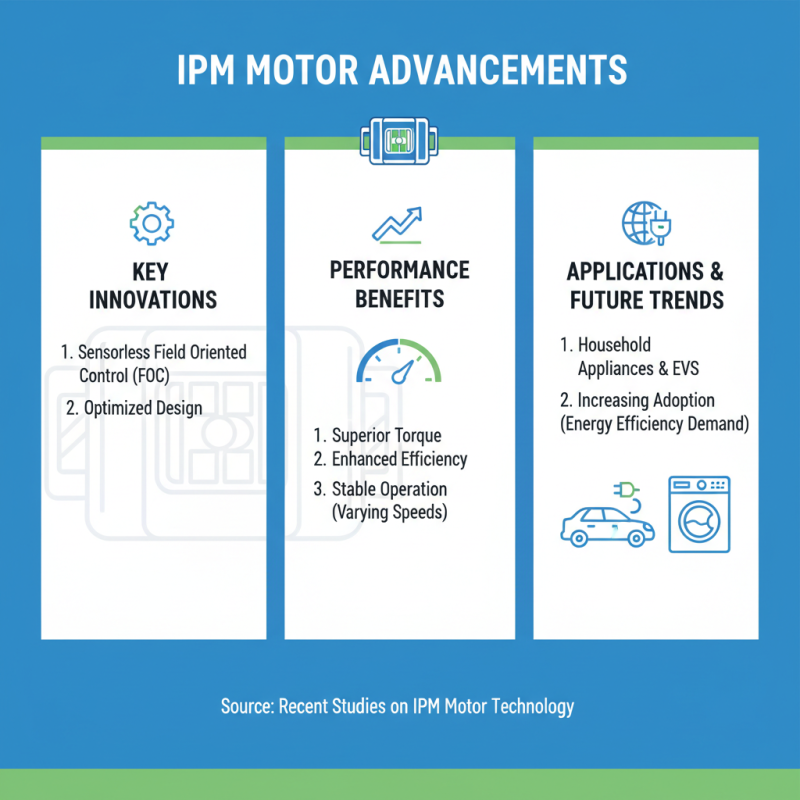

The performance comparison of interior permanent magnet (IPM) motors highlights significant advancements in efficiency and control mechanisms, particularly through the development of sensorless Field Oriented Control (FOC) systems. Recent studies indicate that these motors demonstrate superior torque performance and operational stability across varying speeds, making them highly suitable for a wide array of applications, from household appliances to electric vehicles. As engineers and manufacturers continuously focus on optimizing design, the adoption of IPM technology is expected to surge, driven by consumer demand for energy-efficient solutions.

When evaluating IPM motors, it is essential to consider their operational efficiency. According to industry reports, motor control technologies are expected to grow significantly, reflecting the increasing emphasis on renewable energy and power electronics. The Intelligent Power Module (IPM) market is paving the way for smarter energy solutions, which not only reduce energy consumption but also enhance system reliability.

**Tip:** When selecting an IPM motor, prioritize features such as torque density and thermal management to ensure optimal performance in your specific application. Additionally, invest in models that offer integrated control systems for improved efficiency and ease of use. Another key consideration is the availability of support for obtaining spare parts and maintenance services, which can significantly impact long-term performance.

Future Trends in IPM Motor Technology and Applications

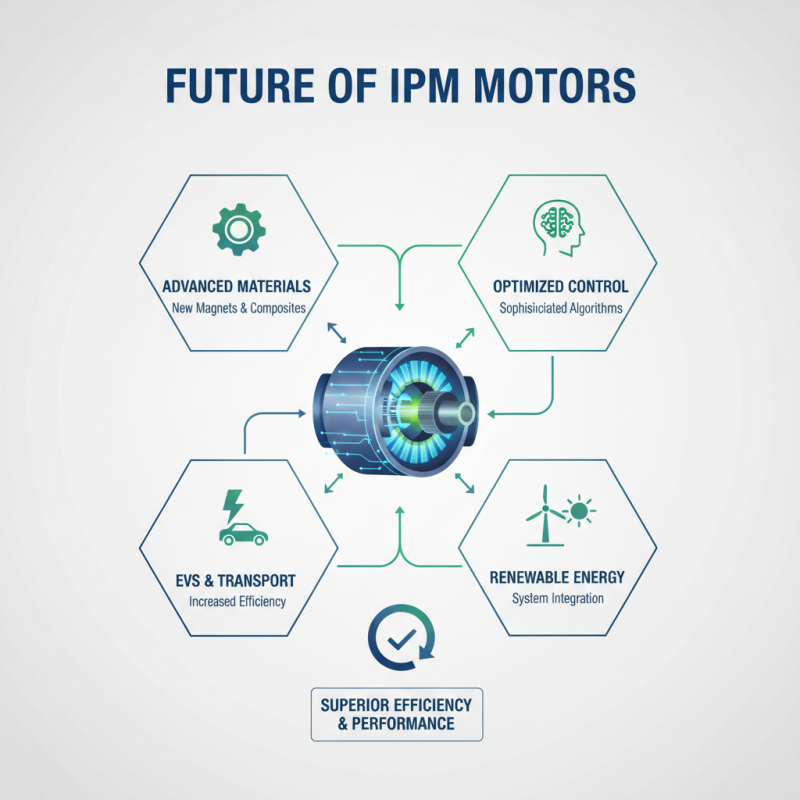

In recent years, Interior Permanent Magnet (IPM) motors have gained significant traction due to their superior efficiency and performance. As we look toward the future, trends indicate that advancements in materials and manufacturing processes will continue to enhance the capabilities of IPM motors. Innovations such as the integration of advanced magnets and sophisticated control algorithms are expected to optimize their operational efficiency, making them indispensable in various applications, from electric vehicles to renewable energy systems.

Tips: When selecting an IPM motor for your application, consider the specific requirements like load conditions and environmental factors. Additionally, staying updated on the latest technological advancements can help you make informed decisions about your purchases.

Furthermore, the evolution of IPM motor technology is paving the way for smart applications. With the rise of the Internet of Things (IoT) and artificial intelligence, future IPM motors will likely feature enhanced connectivity and real-time monitoring capabilities. This will not only improve efficiency but also enable predictive maintenance, reducing downtime and operational costs.

Tips: To maximize the benefits of smart IPM motors, invest in software solutions that can analyze performance data, allowing for proactive maintenance and better system integration.

Related Posts

-

Why IPM SYNRM Motors Are Revolutionizing Energy Efficiency in Modern Applications

-

How to Choose the Right IPM SynRM Motor for Your Next Project

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Unveiling the Efficiency: How 180V Permanent Magnet DC Motors Revolutionize Electric Vehicle Performance

-

Top 5 Benefits of Neodymium Magnet Motors You Need to Know

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology