Top Magnets for Motors What You Need to Know

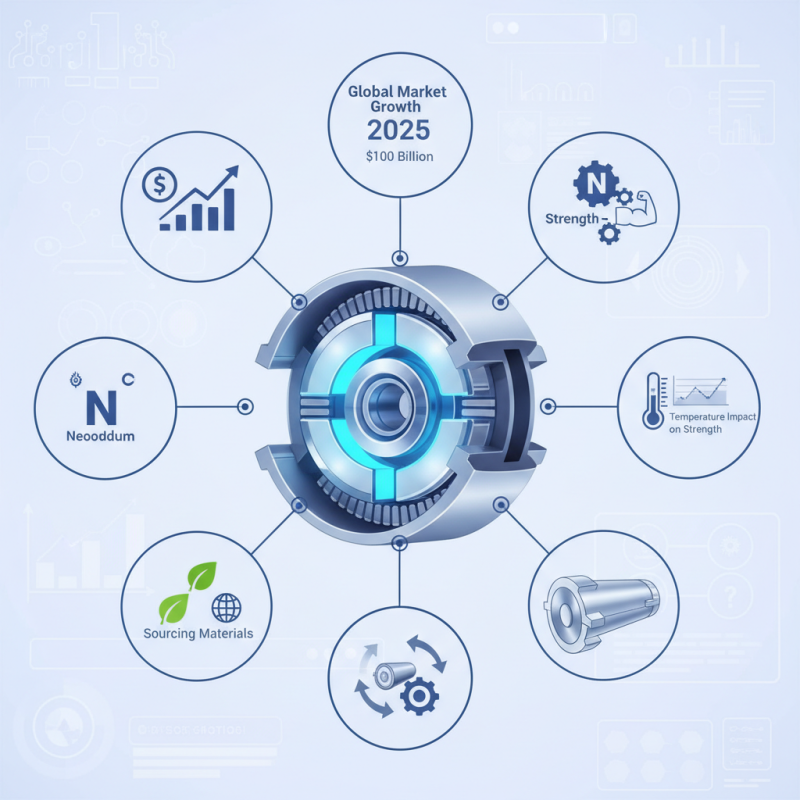

When discussing magnets for motors, one must consider their vital role in electrical engineering. According to a recent report by MarketsandMarkets, the global magnetic materials market is anticipated to reach $100 billion by 2025. Innovative electric motors rely heavily on high-performance magnets.

Magnets for motors can significantly affect efficiency and output. Neodymium, for instance, is widely used for its remarkable strength-to-weight ratio. However, not all magnets are created equal. Some applications may require specific types, creating a complex landscape of choices.

It’s essential to understand how different magnets perform under varying conditions. For example, temperature fluctuations can impact magnet strength. Ongoing research and development are crucial to optimize performance. Exploring the future of magnets for motors reveals both potential and challenges. The industry continues to evolve, but questions remain about sustainability and sourcing materials.

Top Magnets for Motors: Understanding Magnetic Properties

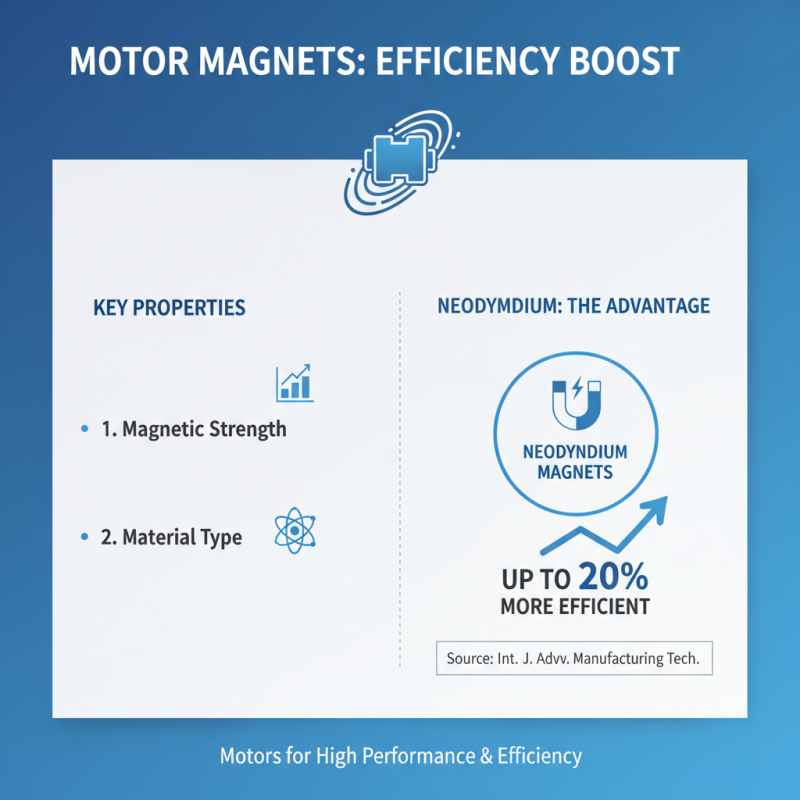

When discussing magnets for motors, understanding magnetic properties is essential. Magnetic materials play a crucial role in efficiency. For instance, neodymium magnets, known for their high magnetic strength, boost motor performance significantly. A study from the International Journal of Advanced Manufacturing Technology emphasized that motors using neodymium show up to 20% improved efficiency compared to traditional magnets.

Magnetic field strength, measured in Tesla, affects how a motor performs. A higher Tesla rating often leads to greater torque and power. However, choosing the right magnet isn't just about strength. It's also about temperature stability and resistance to demagnetization. Industry reports indicate that around 30% of motor failures are linked to inadequate magnet selection.

Some applications may require magnets with specific coercivity. These are critical for maintaining magnetic performance under varying temperatures and conditions. For example, many electric vehicles rely on magnets that can withstand high heat without losing strength. The risk of poor choice affects overall motor reliability and lifespan.

Types of Magnets Used in Electric Motors and Their Applications

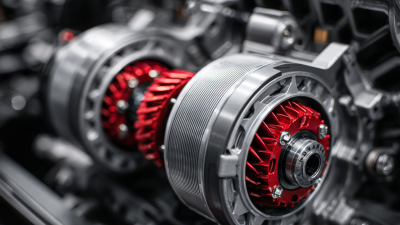

Electric motors rely heavily on magnets for their operation. The most common types include permanent magnets, brushless motors, and inductive magnets. Each type serves a unique purpose and comes with distinct advantages and disadvantages.

Permanent magnets are widely used due to their efficiency. They provide a constant magnetic field. However, they can lose strength over time. This decay can affect motor performance, raising concerns for long-term applications.

Brushless motors utilize electromagnetic induction and do not require brushes. They tend to last longer but can be harder to manufacture.

Inductive magnets, on the other hand, are versatile. They can be switched on and off, offering control in various applications. Though effective, they can lead to heat generation. This heat can challenge motor durability, demanding better heat management strategies.

Understanding these types helps you make informed choices in motor design and selection.

Performance Metrics: Evaluating Magnet Strength and Efficiency

When evaluating magnet strength and efficiency for motors, several performance metrics are crucial. Density, coercivity, and energy product are key factors. Magnet density affects the size and weight of the motor. High-density magnets provide more torque in a smaller package. Coercivity measures a magnet's ability to resist demagnetization. Stronger coercivity means better performance in fluctuating environments.

Efficiency is not solely about power. A magnet's energy product—measured in megajoules per cubic meter—shows how much magnetic energy it can store. Motors with efficient magnets run cooler, which is vital for longevity. However, efficiency can cause unexpected outcomes. Higher efficiency may lead to overloading other components. You must analyze the entire system, not just the magnet.

Some magnets lose strength over time. This physical degradation is a real concern. You won't always see the drop-off coming, either. Routine checks can prevent unexpected failures. Consider also the cost-to-performance ratio. An expensive magnet might not guarantee better performance if the application fluctuates. Always weigh the pros and cons carefully.

Trends in Motor Magnet Technology: Innovations and Industry Standards

Motor magnet technology is evolving rapidly. Innovations are shaping how motors are designed and function. These advancements focus on efficiency and performance. Stronger magnets help increase torque and reduce energy consumption. This is significant for electric vehicles and renewable energy systems.

Industry standards are adapting to these changes. Manufacturers must meet new regulations for magnet materials and performance. The trend is moving towards environmentally friendly materials. This shift can create challenges for some companies. They must balance performance and sustainability. As technology progresses, the future of motor magnets looks both promising and complex.

However, not all innovations are perfect. Some new materials may not perform as expected. This can lead to unexpected failures. Engineers must carefully test these new solutions. They often have to revisit their designs. The journey of innovation is filled with trial and error. Embracing these challenges is essential for growth in motor magnet technology.

Top Magnets for Motors: Trends in Motor Magnet Technology

| Magnet Type | Magnetic Strength (Tesla) | Temperature Resistance (°C) | Cost per kg (USD) | Applications |

|---|---|---|---|---|

| Neodymium (NdFeB) | 1.2 - 1.4 | 80 - 200 | 40 - 150 | Electric motors, loudspeakers, wind turbines |

| Samarium Cobalt (SmCo) | 0.95 - 1.3 | 150 - 350 | 90 - 300 | Aerospace, military, medical devices |

| Alnico | 0.8 - 1.2 | 500 - 600 | 20 - 80 | Sensors, guitar pickups, motors |

| Ferrite | 0.2 - 0.45 | 250 - 300 | 5 - 20 | Small motors, toys, audio equipment |

Environmental Impact and Sustainability Considerations for Motor Magnets

The development of motor magnets raises important environmental questions. These magnets play a crucial role in electric motors and generators. However, sourcing raw materials is a significant concern. Many rare earth elements used in magnets come from mining operations that can cause ecological damage. Water pollution and habitat destruction are common issues.

Moreover, the lifecycle of these magnets is important to consider. Recycling options for motor magnets are limited. This often leads to increased waste in landfills. Alternatives need exploration to mitigate this impact. Innovative designs and sustainable materials can offer solutions.

The push for sustainability is critical in this sector. Technologies that reduce reliance on rare earth elements are emerging. This shift could lessen the environmental footprint. The path forward may not be clear yet. Industry players must engage in ongoing conversations about their choices. Each decision has consequences for the planet.

Related Posts

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology

-

Top 10 Best Magnets for Motors to Boost Performance and Efficiency

-

2025 Top 5 Permanent Magnet DC Motor 180V Options for Enhanced Performance

-

What is a Permanent Magnet DC Motor and How Does it Work

-

How to Choose the Right PM Motor for Your Application?

-

2026 Best Electric Motor Magnet Choices for Optimal Performance?