2025 Top PMDC Motor Applications and Benefits You Need to Know

In recent years, the demand for efficient and versatile motor solutions has led to the increased popularity of PMDC motors, or Permanent Magnet Direct Current motors. These motors are distinguished by their ability to deliver high performance with a compact design, making them ideal for a wide range of applications, from automotive systems to industrial automation. According to Dr. Jane Smith, a leading expert in motor technology, “The adaptability and efficiency of PMDC motors make them essential in driving innovation across various industries.”

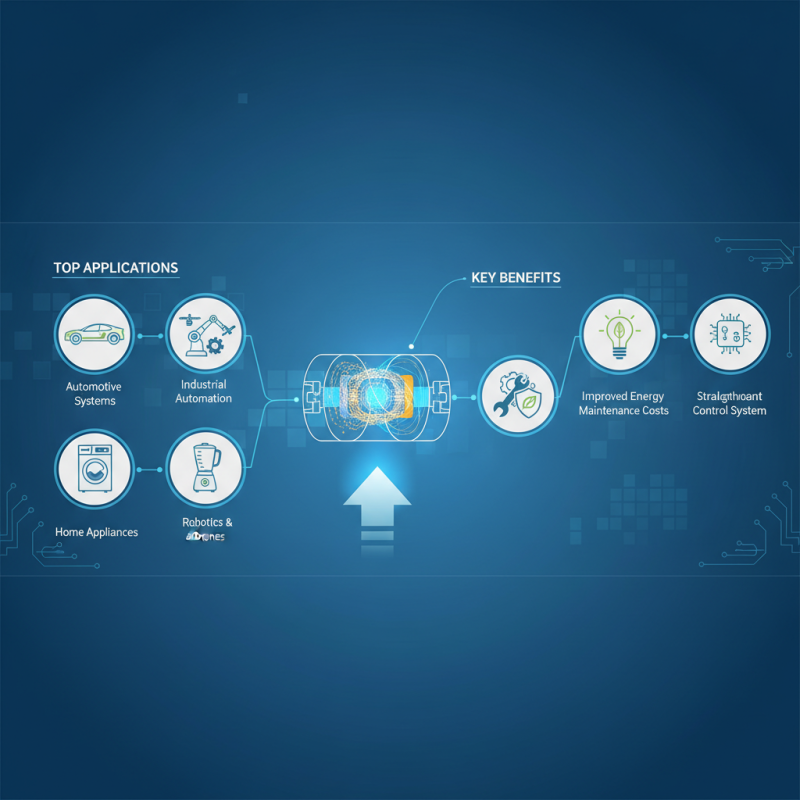

As we look toward 2025, understanding the applications and benefits of PMDC motors will be crucial for businesses looking to enhance their technological capabilities. Their advantages include improved energy efficiency, reduced maintenance costs, and a more straightforward control system, all of which contribute to their growing adoption. In this article, we will explore the top applications of PMDC motors and the transformative benefits they provide, ensuring that stakeholders are well-equipped to leverage this technology to its fullest potential.

Top Industries Utilizing PMDC Motors in 2025

Permanent Magnet Direct Current (PMDC) motors are making significant waves across various industries in 2025 due to their efficiency and versatility. These motors are particularly prominent in the automotive sector, where they are increasingly used in electric vehicles (EVs). According to a recent industry report, the global electric vehicle market is projected to grow at a CAGR of 24% from 2023 to 2030, driving demand for efficient PMDC motors. EV manufacturers benefit from the compact size and high torque-to-weight ratio of these motors, facilitating enhanced performance and energy efficiency.

Tip: When selecting a PMDC motor for your application, consider factors such as torque requirements and thermal management to ensure optimal performance. Furthermore, ensure compatibility with your control systems to maximize efficiency and reduce downtime.

Tip: Regular maintenance and monitoring of PMDC motors can extend their lifespan and enhance operational reliability, especially in critical applications where failure is not an option.

Key Advantages of PMDC Motors for Modern Applications

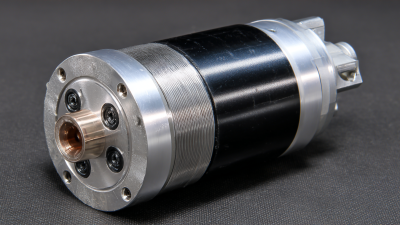

Permanent Magnet DC (PMDC) motors have become a cornerstone in modern technology due to their distinct advantages over traditional motor types. One key benefit is their excellent power-to-weight ratio, which makes them ideal for applications where space and weight are critical considerations, such as in aerospace or portable power tools. The simplicity in their construction also leads to reduced maintenance needs. These motors do not require external brushes for operation, which not only diminishes wear but also prolongs their operational lifespan, enhancing reliability in demanding environments.

Another significant advantage of PMDC motors is their precise speed control. This feature is pivotal in applications that require accurate motion control, such as robotics or automated manufacturing systems. The ability to provide instant torque and smooth operation at varying speeds allows for greater flexibility in design and application, making them suitable for a wide range of sectors, from medical devices to automotive systems. Moreover, their high efficiency contributes to lower energy consumption, aligning with the global push towards sustainable and eco-friendly technology solutions. Overall, the performance and adaptability of PMDC motors position them as a preferred choice for many modern applications.

Emerging Trends in PMDC Motor Technology

In recent years, permanent magnet direct current (PMDC) motors have gained attention for their efficiency and versatility in various applications. One of the emerging trends in PMDC motor technology is the integration of advanced control systems that enhance their performance. These systems utilize sophisticated algorithms to optimize speed and torque, resulting in improved energy efficiency and responsiveness. By implementing techniques such as field-oriented control (FOC), manufacturers can significantly reduce energy losses and enhance the overall functionality of PMDC motors, making them suitable for demanding applications in robotics and automation.

Another notable trend is the increasing focus on miniaturization and lightweight designs. As industries aim to reduce material costs and improve portability, PMDC motors are being designed with smaller dimensions and reduced weight, without compromising on power output. This shift not only facilitates easier integration into compact systems but also enhances the usability of electric and hybrid vehicles. Furthermore, advancements in materials, such as the use of high-performance magnets and advanced rotor designs, are enabling PMDC motors to deliver better torque-to-weight ratios, thereby expanding their potential applications across different sectors, including aerospace and medical devices.

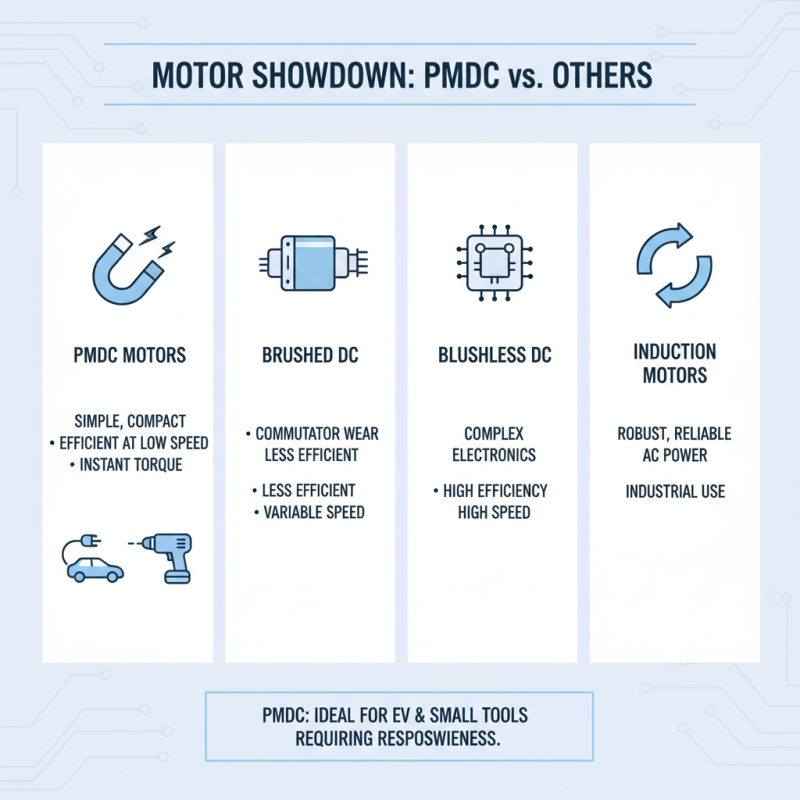

Comparative Analysis: PMDC Motors vs. Other Motor Types

When comparing Permanent Magnet DC (PMDC) motors to other motor types such as brushed and brushless DC motors, as well as induction motors, several key differences emerge, determining their suitability for various applications. PMDC motors stand out for their simplicity and compact design, which make them particularly efficient in low-speed operations. Their construction allows for a direct torque output, which is ideal in applications requiring immediate responsiveness, such as electric vehicles and small power tools.

In contrast, brushed DC motors, while similar in operation to PMDC motors, typically involve more maintenance due to their brush and commutator wear over time. Brushless DC motors eliminate these issues by using electronic commutation, leading to longer lifespans and reduced maintenance, though they often come with higher complexity and cost. Induction motors, on the other hand, are favored for high-power applications and can handle variable load conditions, but they generally lack the speed control and torque characteristics that PMDC motors deliver at low speeds. In this comparative analysis, PMDC motors present a compelling choice for applications where simplicity, immediate torque, and efficient operation are prioritized.

Future Outlook: Innovations in PMDC Motor Applications

The advancements in Permanent Magnet Direct Current (PMDC) motors mark a significant trend in various industrial applications, showcasing their growing importance and versatility. According to a recent industry report, the global PMDC motor market is projected to reach $2.5 billion by 2025, driven by increasing demand in sectors such as automotive, robotics, and consumer electronics. The integration of these motors into electric vehicles (EVs) is particularly noteworthy; with approximately 20% of new automotive sales expected to be electric by 2025, the need for efficient and compact PMDC solutions is becoming critical.

Furthermore, innovations in PMDC motor technology are paving the way for enhanced efficiency and performance. Advances in materials and design—such as the utilization of rare-earth magnets—have enabled manufacturers to produce motors that are not only more powerful but also smaller and lighter. A recent survey highlights that 76% of engineers believe that better energy efficiency in PMDC motors will directly contribute to sustainability efforts within their organizations. As energy regulations become more stringent, these innovations will not only meet the demands of modern applications but will also help industries comply with environmental standards, making PMDC motors a key player in the evolving landscape of electromechanical systems.

2025 Top PMDC Motor Applications and Benefits

This chart illustrates the expected growth percentages of various PMDC motor applications by 2025. Electric vehicles are anticipated to dominate the market, followed by home appliances and medical devices. The data highlights the expanding role of PMDC motors across different sectors, showcasing their versatility and increasing adoption.

Related Posts

-

What is a Permanent Magnet DC Motor and How Does it Work

-

2025 Top 5 Permanent Magnet DC Motor 180V Options for Enhanced Performance

-

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

-

10 Tips for Choosing the Right PMSM Electric Motor for Your Application

-

Revolutionizing Efficiency: The Role of Direct Current Permanent Magnet Motors in Modern Renewable Energy Systems

-

Top 10 Best Magnets for Motors to Boost Performance and Efficiency