Top 10 Tips for Choosing a Permanent Magnet DC Motor 180V for Your Project

When embarking on a project that requires precision and efficiency, selecting the right motor is crucial. The "permanent magnet DC motor 180V" stands out as a reliable option in various applications, from robotics to electric vehicles. Dr. Emily Johnson, a leading expert in motor technology, emphasizes, "The right choice of motor not only enhances performance but also ensures long-term reliability in demanding environments." This sentiment highlights the importance of careful consideration when choosing a motor for specific project requirements.

In the world of engineering, choosing a permanent magnet DC motor 180V involves understanding its specifications and how they align with the intended application. Factors such as torque, speed, and efficiency play vital roles in the selection process. As projects become more complex, the need for precision in this choice becomes increasingly important. This guide aims to provide valuable insights and tips for making an informed decision, ensuring that the motor contributes positively to the overall success of your project. Whether you are a seasoned engineer or a hobbyist, understanding the nuances of the permanent magnet DC motor 180V can greatly influence the outcome of your endeavors.

Understanding the Basics of Permanent Magnet DC Motors

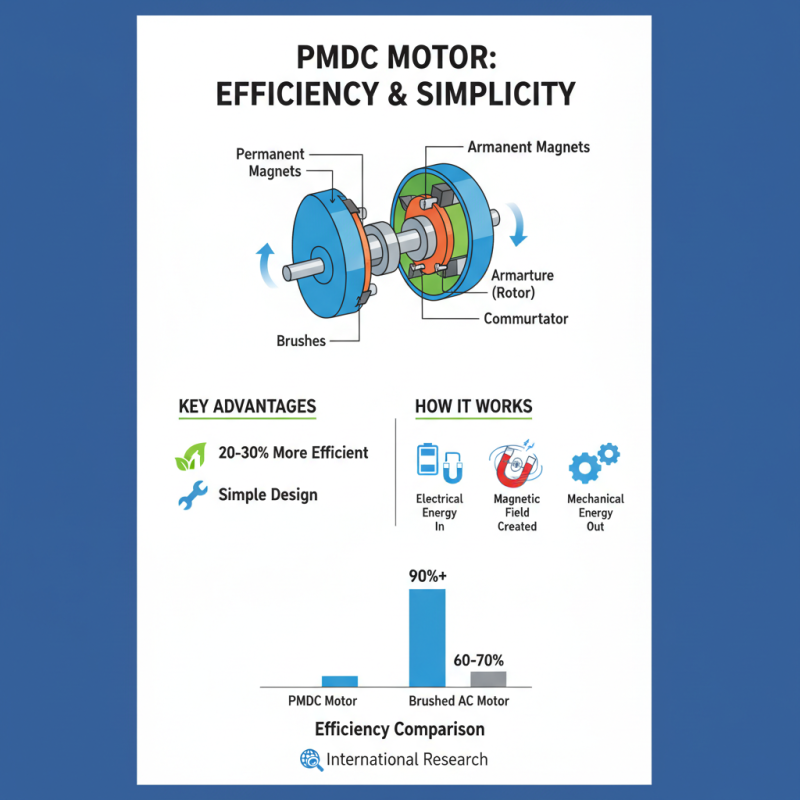

Permanent Magnet DC (PMDC) motors are widely utilized in various applications due to their excellent efficiency and simplicity. Understanding the basic components and functionality of these motors can significantly impact their performance in your projects. A PMDC motor operates on the principle of magnetic fields, where a permanent magnet provides the magnetic field, allowing for the conversion of electrical energy into mechanical energy. International research indicates that PMDC motors are 20-30% more efficient than their brushed AC counterparts, making them an attractive choice for energy-conscious designs.

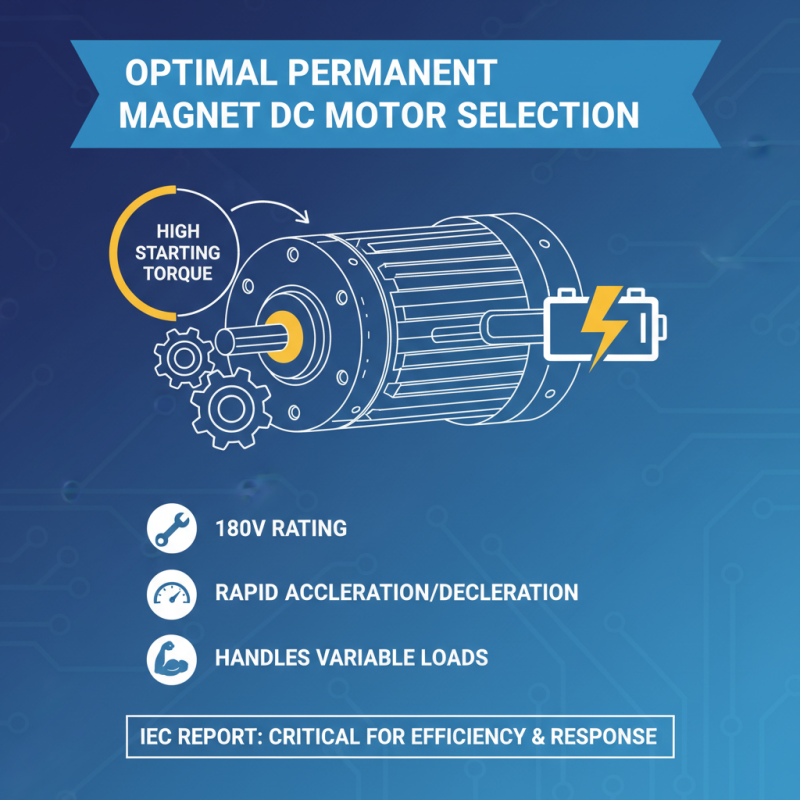

Additionally, the voltage rating of 180V in PMDC motors is critical for ensuring optimal performance. A motor operating at this voltage can deliver higher torque and speed, which is pivotal for applications requiring swift and robust performance. According to industry reports, PMDC motors rated at higher voltages exhibit better thermal performance and longevity, reducing the need for frequent maintenance. Furthermore, with the growing trend towards automation and electric vehicles, market analysis suggests that PMDC motors are projected to witness a CAGR of approximately 5.4% between 2022 and 2028, indicating a robust demand and innovation in this sector. Understanding these fundamentals aids in selecting the right motor for your specific application needs.

Key Specifications to Consider for 180V DC Motors

When selecting a permanent magnet DC motor with a voltage rating of 180V, it is essential to consider several key specifications that will ensure optimal performance for your project. One of the primary factors to evaluate is the motor's torque characteristics. According to a report by the International Electrotechnical Commission (IEC), the torque output is critical in applications requiring rapid acceleration and deceleration. You should look for a motor that can provide high starting torque to handle variable loads effectively, as this can significantly affect the efficiency and response time of your system.

Another crucial specification to consider is the motor's speed range and operating efficiency. A study from the Electric Power Research Institute (EPRI) indicates that DC motors can achieve efficiencies exceeding 90% at optimal load conditions. Understanding the load requirements and ensuring that the motor operates efficiently across its intended speed range can lead to significant energy savings. Furthermore, the thermal characteristics and cooling capabilities of the motor should not be overlooked, as proper thermal management can prevent overheating and prolong motor life, enhancing reliability in demanding applications.

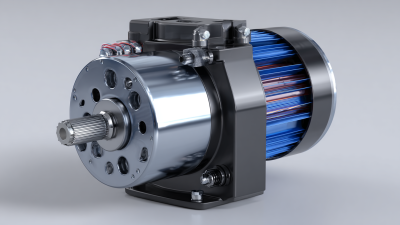

Finally, the physical dimensions and mounting options of the motor are vital to ensure compatibility with your project's design constraints. A compact motor design can often be more beneficial in systems with limited space. Careful attention to these specifications will not only aid in choosing the right 180V DC motor but also enhance the overall performance and longevity of your project.

Evaluating Motor Performance and Efficiency for Your Needs

When selecting a permanent magnet DC motor, particularly at the 180V level, understanding motor performance and efficiency is crucial for optimizing your project. The efficiency of a motor can significantly influence overall system performance, affecting both operational costs and environmental impact. According to a report by the Department of Energy, efficient motors can save organizations up to 60% on energy costs compared to standard motors. This aspect is especially critical in industrial applications where motors operate for extended periods.

Motor performance is typically evaluated through parameters such as torque, speed, and power output. A well-designed 180V permanent magnet DC motor should offer a high torque-to-weight ratio, enabling better performance under load. Various tests have shown that motors with higher efficiency ratings (greater than 90%) not only provide better performance but also longer lifespans. It’s essential to select a motor that meets the specific demands of your application. For projects requiring rapid changes in speed or direction, look for motors equipped with advanced control features, which can enhance responsiveness while maintaining efficiency, making them suitable for dynamic environments.

Performance Comparison of 180V Permanent Magnet DC Motors

This chart presents the performance metrics of different 180V Permanent Magnet DC Motors based on key parameters such as efficiency, torque, and speed. It helps in evaluating which motor might best fit your project needs.

Assessing Compatibility with Your Project's Power Supply

When selecting a Permanent Magnet DC Motor (PMDC) with a voltage rating of 180V for your project, assessing compatibility with your project's power supply is crucial. The power supply not only influences the overall performance of the motor but also affects its efficiency and lifespan. According to a report by the International Electrotechnical Commission (IEC), mismatched voltage supply can lead to increased heat generation, reduced torque output, and ultimately, motor failure. Therefore, ensuring that your power supply can consistently deliver the required 180V is vital to avoid potential issues.

Additionally, understanding the nature of your power supply—whether it is a regulated supply or not—plays a significant role in motor selection. A regulated power supply provides a stable voltage, allowing for optimal motor operation. In contrast, an unregulated supply may result in voltage fluctuations, which can adversely affect performance. A study from the Electric Power Research Institute (EPRI) highlights that even minor inconsistencies in voltage can lead to a 10-20% increase in operational inefficiencies. Thus, evaluating the compatibility of your PMDC motor with the power supply will not only enhance productivity but also ensure the longevity of your motor within its operational environment.

Top 10 Tips for Choosing a Permanent Magnet DC Motor 180V for Your Project - Assessing Compatibility with Your Project's Power Supply

| Tip No. | Tip | Description | Considerations |

|---|---|---|---|

| 1 | Voltage Rating | Ensure the motor's voltage rating matches your power supply. | Using a mismatched voltage can damage components. |

| 2 | Current Requirements | Check the motor’s current draw under load. | Ensure your power supply can handle peak currents. |

| 3 | Speed Rating | Determine the required RPM for your application. | Over-speeding can burn out the motor. |

| 4 | Motor Size | Select a motor size appropriate for your space. | Make sure there’s room for heat dissipation. |

| 5 | Load Type | Consider the type of load: constant, variable, or dynamic. | Choose motors that can handle your load type. |

| 6 | Environmental Factors | Assess ambient temperature and humidity. | Select motors rated for specific environmental conditions. |

| 7 | Mounting Options | Check if the motor is compatible with your mounting setup. | Misalignment can cause wear and tear. |

| 8 | Efficiency | Consider the efficiency rating of the motor. | Higher efficiency can reduce overall operating costs. |

| 9 | Maintenance Requirements | Identify motor maintenance needs and schedules. | Regular maintenance is key to longevity. |

| 10 | Cost Consideration | Evaluate the budget for purchasing the motor. | Consider total cost of ownership, including maintenance. |

Cost Considerations and Budgeting for Motor Selection

When selecting a Permanent Magnet DC Motor (PMDC) for projects that operate at 180V, cost considerations play a crucial role in the budgeting process. The financial implications of motor selection can vary significantly based on factors such as motor specifications, expected lifespan, and maintenance requirements. According to a recent industry analysis, approximately 25-30% of project budgets allocated for motors can be attributed to their initial cost, but lifecycle costs should also be taken into account. These lifecycle costs include operational efficiency, energy consumption, and potential downtime during maintenance, which can all impact overall project economics.

In the realm of budgeting, it is essential to consider not only the purchase price of the motor but also its energy consumption over time. A study published by the International Energy Agency highlights that optimizing the energy efficiency of motors can lead to savings of up to 50% in operational costs. Organizations should also evaluate the total cost of ownership (TCO), which encompasses installation, operational, and maintenance expenses over the motor’s entire lifespan. This comprehensive approach ensures that the motor selected not only fits the project budget but also aligns with long-term operational efficiency and sustainability goals, making it a smart investment for any engineering project.

Related Posts

-

2025 Top 5 Innovations in Axial Flux Permanent Magnet Motor Technology

-

10 Essential Tips for Choosing the Right Magnets for Motors

-

What is a Permanent Magnet DC Motor 90V and How Does it Work

-

Unleashing Efficiency in Electric Motors with Permanent Magnet Rotor Innovations

-

Top 10 Benefits of Neodymium Magnet Motors for Renewable Energy Solutions

-

Unlocking Efficiency: The Science Behind Using Magnets for Motors in Modern Technology