Magnetic Encoders: Enhancing Precision in Motion Control

What is a Magnetic Encoder?

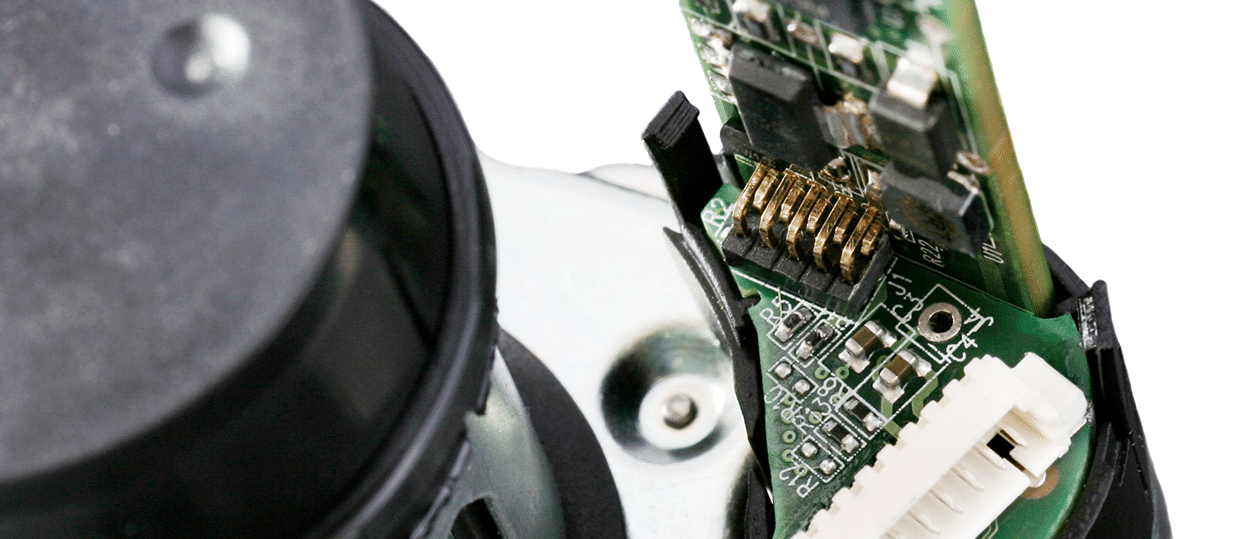

Magnetic encoders are crucial components used to measure the position, velocity, and direction of rotating shafts. They rely on magnetic fields to detect changes in motion with high precision.

How do Magnetic Encoders work?

Magnetic encoders use a magnetised disk or ring paired with a sensor to generate electrical signals, which are processed to give accurate feedback on movement. This technology ensures robust and efficient performance in various applications.

Advantages of Magnetic Encoders

- Less wear and tear compared to optical encoders

- Often more affordable while delivering high accuracy

- Ideal for use in space-constrained environments like Rotalink’s miniature gearmotors

- Performs well under harsh conditions like high temperatures and vibrations

Applications of Magnetic Encoders in Miniature Gearmotors

Magnetic encoders play a crucial role in Rotalink’s miniature gearmotors, providing feedback to ensure precision in applications ranging from robotics to medical devices.

At Rotalink, we offer advanced miniature gearmotor solutions that integrate magnetic encoder technology, empowering OEMs with reliable, cost-effective motion control systems for a wide range of applications.