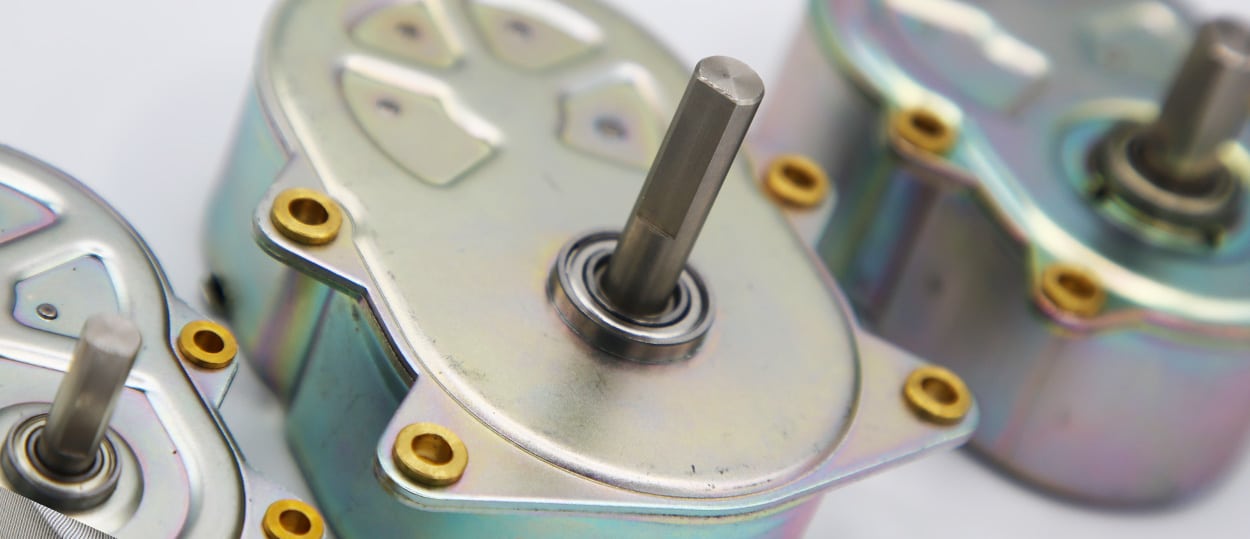

Gear ratios play a critical role in mechanical power transmission, directly influencing speed, torque, and efficiency in motor-driven systems. Whether designing miniature gearmotors for automation, robotics, or industrial applications, understanding gear ratios is essential for optimising performance and reliability.

What is a Gear Ratio?

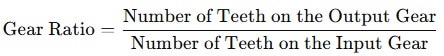

A gear ratio defines the relationship between the input (driving) gear and the output (driven) gear. It is expressed as:

For example, if a motor’s pinion gear has 10 teeth and drives a larger gear with 50 teeth, the ratio is 5:1. This means the output shaft will rotate one-fifth as fast as the input while delivering five times the torque.

How Gear Ratios Affect Motor Performance

Speed Reduction and Torque Multiplication

A higher gear ratio (e.g., 10:1) reduces speed but significantly increases torque.

This is useful for applications requiring high force at low speeds, such as robotic arms, door actuators, and industrial automation.

Speed Increase and Torque Reduction

A lower gear ratio (e.g., 1:3) allows the output shaft to rotate faster than the input.

This is ideal for applications where high-speed rotation is required with low torque demand, such as centrifugal pumps and small fans.

Efficiency Considerations

Higher gear ratios introduce more mechanical losses due to friction and heat dissipation.

Proper gear material selection and lubrication help maintain efficiency.

Precision and Load Handling

Fine-tuned gear ratios allow for precise movement and smooth operation, especially in stepper motor-driven systems.

Used in medical devices and optical instruments, where accuracy is critical.

Selecting the Right Gear Ratio for Your Application

When designing a miniature gearmotor, engineers must consider:

- Required speed and torque – What is the load demand?

- Space constraints – Compact applications may need planetary or spur gear solutions.

- Efficiency needs – Minimising energy losses ensures optimal performance.

- Durability – Proper materials and lubrication enhance longevity.

At Rotalink, we provide custom gearmotor solutions, optimising gear ratios for your specific application - from vending machines to automated security systems.

How Rotalink Optimises Gear Ratios for Miniature Gearmotors

At Rotalink, we specialise in miniature gearmotor design, providing bespoke solutions for OEMs across multiple industries. Our engineering expertise allows us to tailor gear ratios for maximum efficiency and precision. As well as to offer a range of spur, planetary, and hybrid gearing solutions.

We ensure that every gear ratio is optimised for performance, longevity, and reliability—helping you achieve the best possible results in your application.

Understanding gear ratios is fundamental to designing efficient motor-driven systems. The right ratio can enhance torque, speed, efficiency, and precision, making it a crucial design element in automation, robotics, and industrial applications.

At Rotalink, we help engineers and designers navigate the complexities of gear selection, ensuring your miniature gearmotors are perfectly tuned for optimal performance.