Modern designs increasingly demand compact, efficient, and high-performance components. Miniature gearmotors play a vital role in meeting these challenges, combining precision, reliability, and adaptability to fit within tight design constraints.

Challenges of miniature engineering

Compact designs require:

- Optimised Space Utilisation: Ensuring gearmotors provide power and precision without exceeding size limitations

- Customisation Flexibility: Tailoring performance characteristics such as torque, speed, and noise

- Thermal Efficiency: Avoiding overheating in compact enclosures to maintain reliability.

Miniature gearmotor customisaton solutions

Miniature gearmotors address these challenges by:

- Integrating Gearing: Reducing the need for additional components, saving space

- Custom Gear Ratios: Matching application-specific torque and speed requirements

- Noise Control: Meeting acoustic constraints for sensitive applications

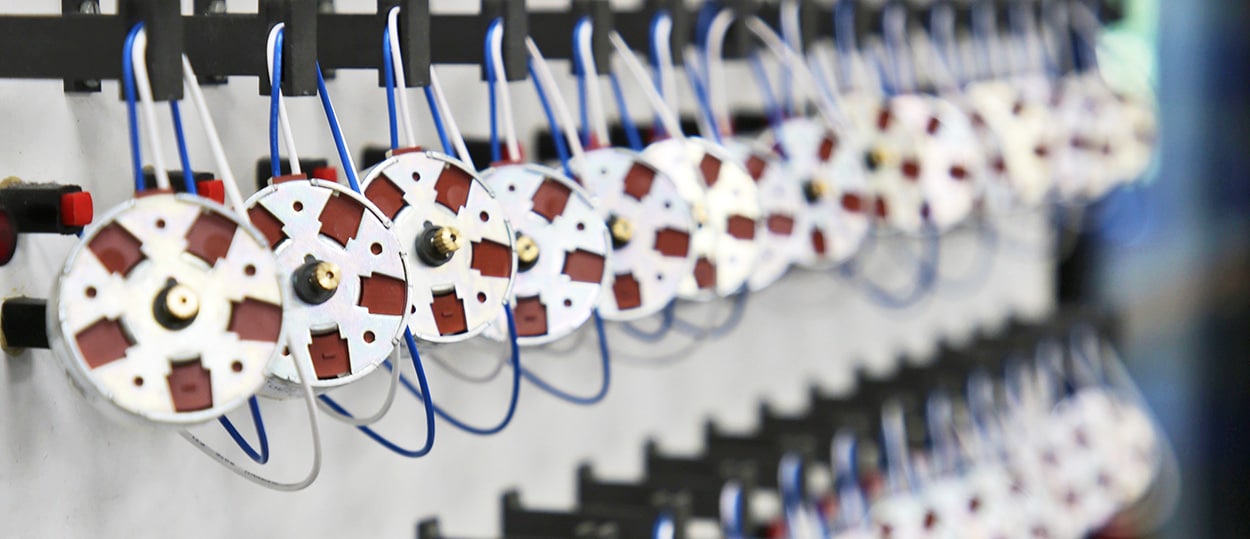

Rotalink’s expertise

At Rotalink, we specialise in designing bespoke gearmotors that meet tight spatial and performance specifications:

- Collaborative Development: Adapting motors to exact customer needs

- Prototyping: Ensuring designs meet practical requirements

- Custom Components: Housing, shafts, and connectors tailored to specific applications

Applications

Medical devices

Miniature gearmotors power surgical tools and diagnostic equipment, offering precise motion in compact spaces, essential for reliable healthcare performance.

Customised gearmotors for precision engineering challenges

Looking for precision engineering solutions in tight spaces? Explore Rotalink’s customised miniature gearmotors, designed to meet unique challenges. Contact us today!