Synchronous motors are a critical component in many industries due to their ability to deliver precise speed control and efficient operation. These motors are engineered to maintain a constant speed under varying loads, making them invaluable for applications where precision and consistency are key.

Let's explore the principles behind synchronous motors, their advantages, and the typical applications where they excel, especially in high-precision tasks.

What Are Synchronous Motors?

Definition of Synchronous Motors

Synchronous motors are a type of AC motor where the rotation of the rotor is synchronised with the frequency of the supply current.

Unlike induction motors, which can slip under varying loads, synchronous motors maintain a constant speed that is exactly in sync with the frequency of the electrical supply, making them highly reliable for applications requiring precise control.

Basic Operating Principles

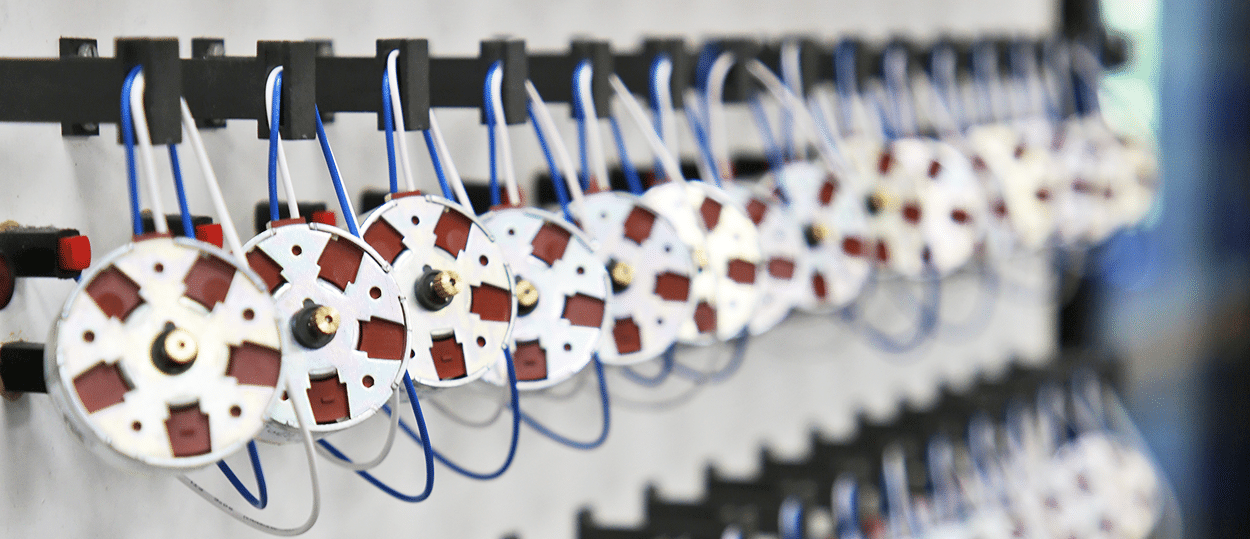

At the heart of synchronous motors are three main components: the rotor, the stator, and the field windings. The stator generates a rotating magnetic field when an alternating current is supplied, while the rotor is designed to rotate at the same rate as this field.

The motor’s speed is determined by the frequency of the AC power supply and remains constant as long as the frequency is stable.

How Synchronous Motors Work

Synchronous motors operate by generating a magnetic field on the rotor through either permanent magnets or electromagnets, which interact with the rotating magnetic field of the stator. The rotor locks in with the stator’s magnetic field and rotates at a speed that matches the supply frequency, thus producing torque. This synchronisation between the rotor and stator fields is what gives the motor its name and unique properties.

Advantages of our Miniature Synchronous Motor

Precise Speed Control

One of the most significant advantages of synchronous motors is their ability to maintain a constant speed regardless of the load, making them ideal for applications where precise speed control is essential. This feature allows these motors to be used in equipment requiring consistent performance, such as in timing and positioning tasks.

High Efficiency

Synchronous motors are known for their high efficiency in converting electrical power into mechanical power. Their ability to operate at unity or leading power factor means that they can significantly reduce power losses and energy costs, making them an economical choice for many industrial applications.

Power Factor Correction

Another advantage of synchronous motors is their ability to improve the power factor of electrical systems. By operating at a leading power factor, synchronous motors can provide reactive power, which helps to balance the load on the power grid and reduce the overall power consumption of the system. This capability makes them particularly valuable in industrial settings where maintaining an optimal power factor is crucial.

Common Applications of Synchronous Motors

Industrial Applications

Synchronous motors are widely used in various industrial applications, including compressors, pumps, and conveyors. Their ability to maintain constant speed under varying loads ensures that these processes run smoothly and efficiently, reducing the risk of mechanical failure and downtime.

High-Precision Tasks

In high-precision tasks such as robotics, CNC machines, and other automated systems, synchronous motors are the preferred choice due to their exact speed control. The ability to synchronise movements precisely allows for accurate positioning and consistent operation, which is critical in applications where even slight deviations can lead to errors or defects.

Miniature Synchronous Motor vs. Other Motor Types

Synchronous vs. DC Motors

Synchronous motors and DC motors differ in their operation and application areas. DC motors offer excellent speed control and torque but require regular maintenance due to the brushes and commutators. Synchronous motors, on the other hand, provide maintenance-free operation with high efficiency and reliability, making them suitable for applications where uptime and longevity are crucial.

How Rotalink Supports Miniature Synchronous Motor Applications

Customisation and Design Support

At Rotalink, we specialise in designing and customising synchronous motors to meet the unique needs of various applications. Our team of expert engineers works closely with clients to develop tailored solutions that align with their specific requirements. Whether it’s for industrial machinery or precision instruments, Rotalink’s motors are designed with quality and performance in mind.

Technical Support and Resources

Rotalink provides comprehensive support throughout the entire process, from initial consultation to after-sales service. Our extensive resources include detailed datasheets, performance graphs, and expert guidance to help customers select the right motor for their needs. With Rotalink, you can be assured of receiving not just a motor, but a complete solution tailored to your application.