Understanding Spur Gears

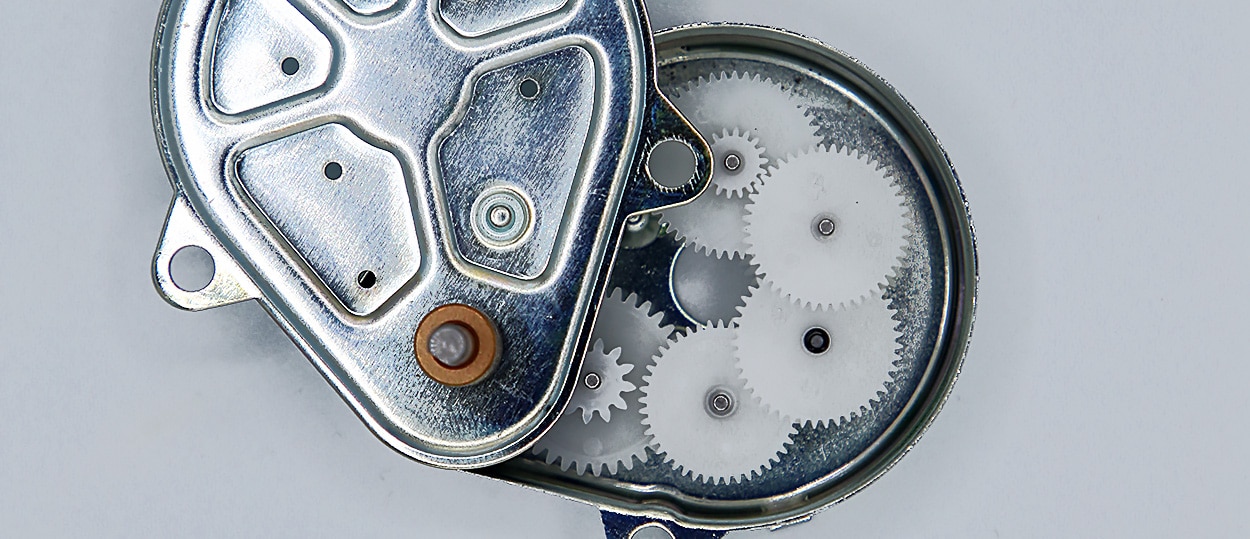

Spur gears are cylindrical gears with straight teeth aligned parallel to the gear’s axis. They are the most common type of gear used in various applications to transmit motion and power between parallel shafts.

Typically made from materials like steel, plastic, or brass, spur gears are valued for their simplicity and effectiveness. In a spur gear motor, these gears mesh together to convert rotational motion from the motor into the desired output, providing torque and speed control.

How do spur gear motors work?

In a spur gear motor, the motor drives a spur gear, which then meshes with another gear to transfer motion. The gear ratio, determined by the number of teeth on the gears, affects the motor's output speed and torque. This configuration allows for precise control, making spur gear motors ideal for applications requiring consistent speed and power.

Advantages of Spur Gear Motors

The simplicity of spur gears means they can be produced at a lower cost compared to more complex gear types. This makes spur gear motors an economical choice for a wide range of applications.

High-Efficiency Spur Gears

Minimal Energy Loss: Spur gears in spur gear motors achieve high efficiency, often reaching up to 98-99%. The straight teeth of spur gears ensure smooth engagement, leading to minimal energy loss during operation.

High-Speed Applications: Spur gear motors excel in high-speed applications due to their efficient power transmission. They provide reliable performance in scenarios where consistent speed and power are critical.

Uniform Load Distribution

Spur gears distribute the load evenly across the teeth, reducing wear and tear. This uniform load distribution enhances the durability of spur gear motors, ensuring long-lasting performance even in demanding environments.

Applications of Miniature Spur Gear Motors

Medical Devices

Miniature spur gear motors are integral in medical devices such as infusion pumps, diagnostic equipment, and surgical tools, where precise control and reliability are paramount. These motors enable accurate movement in compact spaces, ensuring optimal performance in life-saving technologies.

Robotics

In the field of robotics, miniature spur gear motors are crucial for driving small-scale robotic arms, grippers, and mobile platforms. Their compact size and high efficiency allow for precise movement and control in applications where space is limited, such as in consumer robots and medical robots.

Consumer Electronics

From electric toothbrushes to compact cameras, miniature spur gear motors power a wide range of consumer electronics. These motors offer the right balance of torque and speed for small devices, ensuring reliable operation while maintaining a compact footprint.

Automotive Electronics

Miniature spur gear motors are used in various automotive applications such as AC actuators, power seat adjustments, and mirror controls. These motors provide consistent and reliable performance in compact spaces, contributing to the functionality and comfort of modern vehicles.

Industrial Automation

In industrial settings, miniature spur gear motors drive small actuators and automated machinery components, where precision and durability are essential. Their compact size allows for integration into tight spaces, making them ideal for specialised manufacturing equipment and precision control systems.

Rotalink's Spur Gear Motor Solutions

Rotalink specialises in producing high-quality spur gear motors that meet the exacting standards of various industries. Our advanced manufacturing processes ensure that every motor is optimised for performance and reliability.

We offer custom spur gear motor solutions for Original Equipment Manufacturers (OEMs), ensuring that our products meet the specific design and operational requirements of your applications.

Whether you need spur gear motors for automotive, industrial, or consumer electronics applications, Rotalink has the expertise to deliver a solution that fits your needs.