Zero-backlash spur gearheads are precision mechanical components designed to eliminate the play or "backlash" typically found in standard gear mechanisms. Backlash refers to the slight movement or slack between meshing gears, which can negatively impact the accuracy and performance of gear-driven systems. Zero-backlash gearheads address this issue through specialised design and manufacturing techniques.

Key Features:

- Precision Engineering: Zero-backlash spur gearheads are manufactured with extremely tight tolerances and precision machining, ensuring minimal clearance between gear teeth.

- Dual-Stage Design: Often, these gearheads use a dual-stage or preload mechanism, where two sets of gears are preloaded against each other. This constant preload eliminates any free play.

- Material Selection: High-quality materials such as hardened steel, titanium, or advanced composites are used to ensure durability and minimise wear.

- Advanced Lubrication: Specialised lubrication techniques and materials help maintain consistent performance and reduce wear over time.

Benefits

- Enhanced Accuracy: The elimination of backlash ensures that the gearhead transmits motion precisely, which is crucial for applications requiring high positional accuracy.

- Improved Repeatability: Zero-backlash gearheads provide consistent performance, which is essential for tasks that require repetitive movements with high precision.

- Increased Efficiency: By minimising energy loss due to gear play, these gearheads enhance the overall efficiency of the mechanical system.

- Reduced Wear and Tear: The constant preload and precision design reduce the mechanical stress on gear teeth, leading to longer lifespan and lower maintenance requirements.

Application

Zero-backlash spur gearheads are used in a variety of high-precision applications, including:

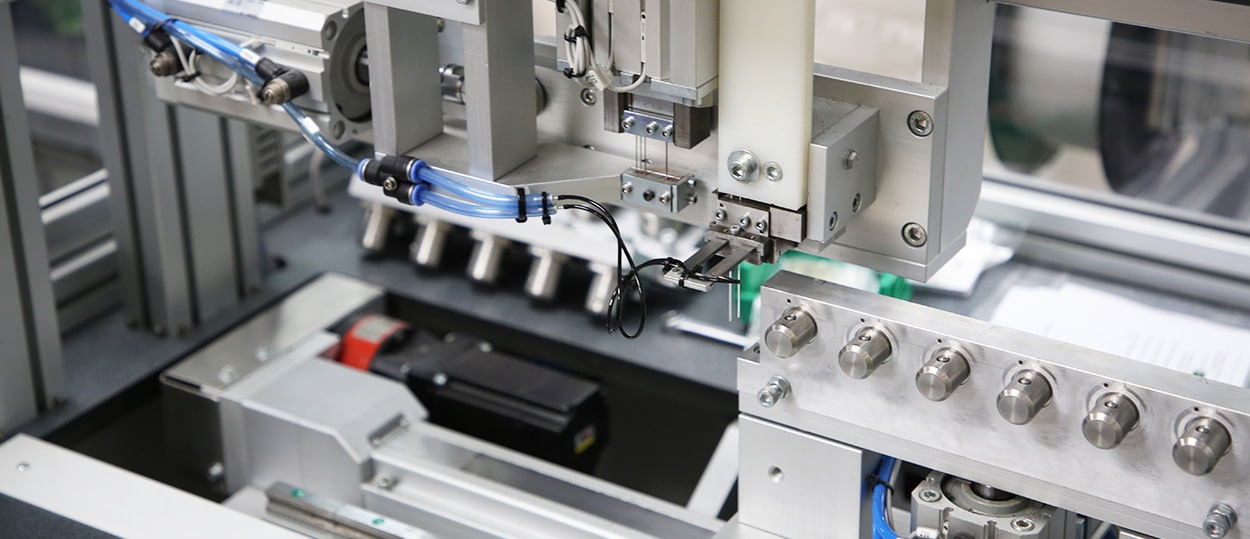

- Robotics: Ensuring precise movement and control in robotic arms and automation systems.

- CNC Machinery: Providing accurate and repeatable positioning in computer numerical control (CNC) machines.

- Medical Devices: Enabling precise control in surgical instruments and diagnostic equipment.

- Aerospace: Enhancing the accuracy and reliability of positioning systems in aircraft and spacecraft.

Rotalink's Contribution

At Rotalink, we specialize in designing and manufacturing zero-backlash spur gearheads tailored to our customers' specific requirements. Our engineering team leverages cutting-edge technology and materials to create gearheads that offer unparalleled precision and durability. Whether you need a custom gearhead for a new application or an upgrade for an existing system, Rotalink provides solutions that meet the highest standards of performance and reliability.

In summary, zero-backlash spur gearheads are essential components in any system requiring high precision and reliability. Their advanced design and construction eliminate the inaccuracies caused by the backlash, making them ideal for a wide range of critical applications. Rotalink’s expertise in this area ensures that you receive a product that meets your exact specifications and delivers consistent, accurate performance.