In the world of mechanical engineering, efficiency stands as a cornerstone of performance and sustainability. Gearmotors, the workhorses of various industrial applications, are no exception. Understanding and optimising gearmotor efficiency is paramount for enhancing performance, minimising operating costs, and reducing environmental impact.

In this comprehensive guide, we delve into the intricacies of analysing gearmotor efficiency and unlocking its full potential.

Understanding Gearmotor Efficiency

Efficiency is the measure of how effectively a gearmotor converts input energy into useful mechanical work while minimising losses. It directly influences the performance, reliability, and economic viability of gearmotor-driven systems.

Key Steps in Analysing Efficiency

Input Power Measurement:

Begin by quantifying the electrical power input to the gearmotor, typically measured in watts (W).

Output Power Calculation:

Determine the mechanical output power of the gearmotor by measuring parameters like torque and rotational speed and using the appropriate formula. This involves measuring parameters such as torque and rotational speed and calculating mechanical power using the formula: Power (W) = Torque (Nm) × Speed (rad/s).

Efficiency Calculation:

Compute gearmotor efficiency by comparing the output power to the input power, expressed as a percentage. Once input and output powers are known, calculate the gearmotor efficiency using the formula: Efficiency (%) = (Output Power / Input Power) × 100.

Loss Analysis:

Identify and quantify various losses within the gearmotor system, encompassing mechanical, electrical, and transmission losses.

Load Variation Effects:

Assess how gearmotor efficiency fluctuates under different load conditions, considering factors like torque, speed, and duty cycle.

Maximising Efficiency: Strategies and Considerations

Load Optimisation:

Match gearmotor selection to the specific application requirements to operate near peak efficiency under typical operating conditions.

Component Selection:

Opt for high-quality components and materials to minimise losses and maximise durability.

Lubrication and Maintenance:

Implement proper lubrication regimes and regular maintenance practices to reduce frictional losses and ensure optimal gearmotor performance.

Temperature Management:

Monitor and control operating temperatures to mitigate efficiency-reducing effects of heat buildup.

Advanced Technologies:

Explore innovative motor technologies and control strategies to enhance efficiency, such as brushless DC motors and energy-efficient motor controllers.

Engineering Excellence at Rotalink

Efficiency analysis and optimisation are essential steps in maximising the performance and longevity of gearmotor-driven systems. By understanding the factors influencing efficiency and implementing effective strategies, manufacturers and end-users can achieve significant improvements in performance, energy savings, and overall system reliability.

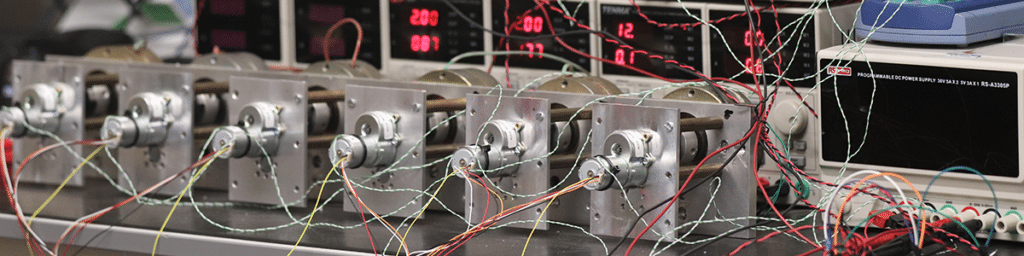

At Rotalink, ensuring the efficiency and reliability of our gearmotors is paramount. We adhere to rigorous testing procedures and employ meticulous fine-tuning processes to achieve the level of efficiency required for each gearmotor.

Rigorous Testing Protocols

Performance Testing:

Before a gearmotor leaves our facility, it undergoes comprehensive performance testing to verify its efficiency, torque output, speed stability, and overall functionality.

Durability Testing:

Our gearmotors are subjected to rigorous durability tests to ensure they can withstand the demands of real-world applications over extended periods. This includes endurance testing under various load conditions and environmental factors.

Temperature Testing:

We assess the thermal performance of our gearmotors to ensure they operate within safe temperature ranges under different operating conditions. This helps prevent efficiency losses due to overheating and ensures long-term reliability.

Fine-Tuning and Optimisation

Customisation:

We work closely with our clients to understand their specific application requirements. By tailoring gearmotor specifications to meet these needs, we optimise efficiency and performance for their unique use cases.

Precision Engineering:

Our team of engineers employs advanced design and manufacturing techniques to minimise internal losses and maximise power transmission efficiency within our gearmotors.

Continuous Improvement:

We are committed to continuous improvement in our manufacturing processes and product designs. Through ongoing research and development efforts, we strive to enhance the efficiency and performance of our gearmotor solutions.

Quality Assurance

ISO Certification:

Rotalink maintains ISO-certified quality management systems to ensure consistency and adherence to industry standards in all aspects of our operations.

Stringent Quality Control:

Every gearmotor undergoes thorough quality control inspections at various stages of production to identify and rectify any potential issues early on, ensuring that only the highest quality products reach our customers.