At Rotalink, quality is more than a promise; it's a fundamental principle embedded in every aspect of our miniature motor manufacturing process. With a dedication to precision and reliability, we ensure that our products meet the highest standards. This article delves into the meticulous quality assurance measures we employ to maintain our reputation as a leading provider of miniature motors and gearmotors.

Rotalink’s Manufacturing Process

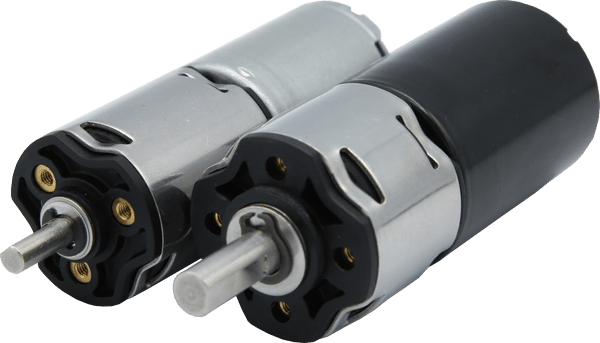

Rotalink’s state-of-the-art manufacturing facilities are the backbone of our high-quality production. Our process begins with the careful selection of raw materials, followed by precision engineering, assembly, and rigorous testing. Each stage is meticulously designed to incorporate quality control measures that guarantee the excellence of our miniature motors and gearmotors.

Our Gearmotors are designed for:

Longevity: Our frequency-controlled AC motors are developed to withstand years of use while reliably being able to perform as intended.

Quiet Operation: We produce gearmotors that can operate within controlled noise limits and we can characterise the gearmotor noise to our customer’s requirements upon request. Further to this, our range of turntable motors is specifically designed for characteristically extremely low vibration and low noise operation that is undetectable by a turntable's audio output.

Accuracy: Our frequency-controlled AC motors and particularly our range of turntable motors are developed to be operated by class-leading motor controllers to maintain consistent speed and precise positioning to deliver the best audio performance.

Quality Standards

We adhere to international quality standards, including ISO certifications, to ensure our products consistently meet or exceed global benchmarks. Our commitment to continuous improvement is evident in our regular audits and compliance checks, which help us maintain and exceed these standards. This philosophy drives us to refine our processes and deliver superior products constantly.

Quality Management System - ISO 9001:2015

A cornerstone of our quality assurance framework is our adherence to the ISO 9001:2015 Quality Management System (QMS). This certification underscores our commitment to maintaining the highest standards in every aspect of our operations. The ISO 9001:2015 certification involves rigorous documentation and auditing processes to ensure our quality management system is effective and consistently applied. This framework helps us ensure that our products and services consistently meet customer and regulatory requirements, and demonstrates our commitment to continuous improvement and customer satisfaction.

Advanced Quality Control Techniques

Incorporating cutting-edge technology, we implement advanced quality control techniques throughout our manufacturing process.

Real-time monitoring and in-process inspections are conducted to detect and address any anomalies immediately. Our automated and manual testing methods are designed to validate the integrity and performance of our motors at every stage.

Rigorous Testing Procedures

Our testing procedures are comprehensive and rigorous. Environmental and stress testing ensure our motors can withstand harsh conditions and prolonged use. Performance testing guarantees that each gearmotor functions as intended, meeting all specified requirements.

These rigorous testing protocols help us deliver products that are both durable and reliable.

Customer Feedback and Continuous Improvement

Customer feedback is vital to our quality assurance strategy. We actively collect and analyse feedback to identify areas for improvement. This ongoing dialogue with our customers energises our continuous improvement processes and allows us to make informed enhancements to our products and processes. Examples of improvements based on customer input demonstrate our commitment to meeting and exceeding customer expectations.

Future of Quality Assurance at Rotalink

As we look to the future, we remain committed to advancing our quality assurance practices to benefit our customers. By staying abreast of industry trends and technological innovations, we continue to enhance our testing methods and manufacturing processes further.

Our vision is to lead the industry in quality assurance, ensuring that our miniature motors and gearmotor transmission systems set the standard for excellence.