We were contacted by a company based in Devon, UK, to assist them with producing resilient gearboxes for their lubricant pumps. The company was founded over a hundred years ago and works to keep vehicles and production lines working without interruption through their intelligent product design. They achieve this through the creation of centralised lubrication and oil filtration systems.

When we we approached regarding the creation of a DC gearbox motor, we knew we would be able to deliver a solution that be perfect for the application. We worked to ensure that our gearmotor would meet our own high expectations in terms of being user-friendly while requiring minimal maintenance.

Product:

26B41/SP3025, SP3179, SP3215, SP3225, SP3231

Description:

4722L/226 12V 50HZ 0.4RPM A

SB5526-048-003-1.2/230 300:1 12V HARDENED SHAFT

4722L/225 230/115V 50HZ 10M A

D2431-09450/225 9-30VDC 36000:1

RY(HT)5124/230 115V 50HZ 1.25RPM LUBE LIGHT MACHINE OIL

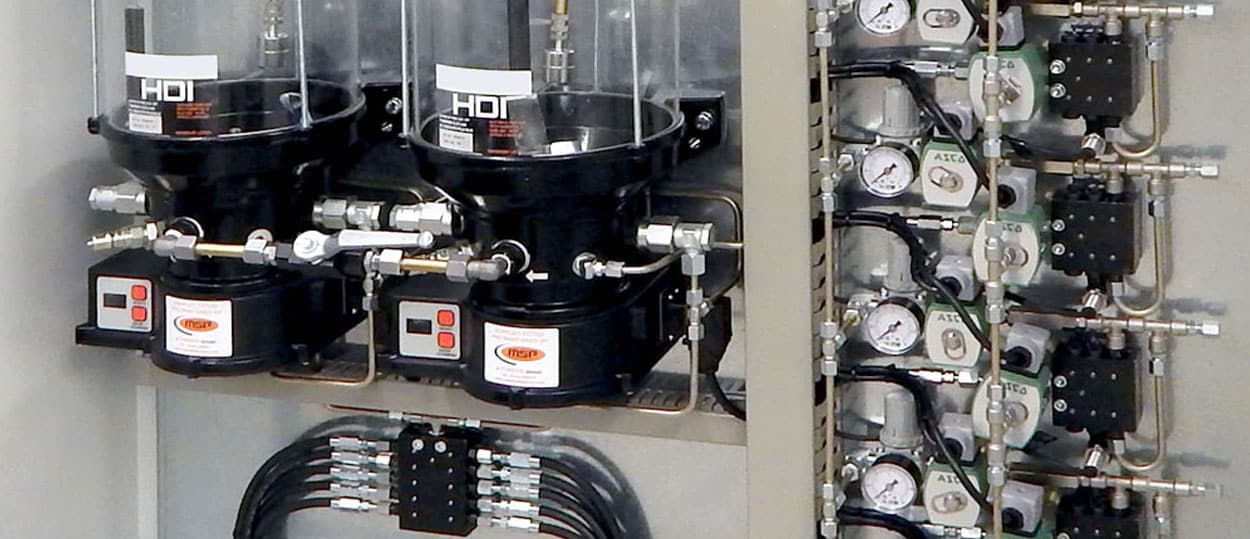

The final application & solution

Our client was looking for hardwearing gearboxes to be used within their automated lubricant pumps that would be able to deliver in terms of performance while requiring a minimum amount of maintenance.

The compact design of the client's lubricant pumps allows for the grease to be simply applied in the necessary areas on industrial vehicles as well as on production lines, while fitting seamlessly into the machinery.

The pumps require DC gearbox motors that operate slowly to provide the demanded level of grease while also being also to withstand the vibrations that come with a machine or vehicle.

After assessing the demands of the gearbox, we established that the best options would be our Type 226 and 230 options. This then allows our client's products to deliver the exact amount of lubrication when it is needed.

| Are you looking for a similar solution for your product? Call our friendly team on +44 (0) 1460 72000 |