In modern business, the need for efficient, compact gearmotor designs is more crucial than ever. The miniature motors we develop here at Rotalink, play key roles in achieving these goals, and deliver high performance in small packages.

Today, we're looking at the integration of miniature motors in compact OEM (Original Equipment Manufacturer) designs and highlighting the expertise and products we provide to our customers.

The Importance of Compact Gearmotors in OEM Designs

Compact gearmotors are essential for modern OEM designs due to their space-saving benefits, high efficiency, and versatile applications. With their small size, our compact gearmotors can be integrated into tight spaces without affecting their performance, making them ideal for a wide range of industries.

The ability to deliver precise motion control in compact configurations enables innovative product designs and enhances functionality.

Considerations for Integrating Compact Gearmotors

Space Constraints - When integrating compact gearmotors in limited spaces requires innovative design solutions best suited to the space available. Our team is here to support you in selecting the right gearmotor to match the design and performance required for your application.

Performance Requirements - We work hard to ensure the gearmotors we provide meet the necessary torque, speed, and precision while balancing power usage is critical for successful integration. Compact gearmotors must deliver reliable performance in demanding conditions.

Thermal Management - Effective cooling is vital for managing heat dissipation within a compact design. We have the software needed to understand thermal management and simulate the environment to ensure the longevity and reliability of the gearmotor. Find out more

Noise and Vibration - Often the applications our gearmotors are used in applications where minimising noise and vibration is important. Especially for maintaining the functionality and user experience in compact systems. Quiet operation is especially crucial in applications such as medical devices and consumer electronics.

Applications of Compact Gearmotors in OEM Designs

Compact gearmotors are used in household consumer products to provide precise motion control and enhance user experience. Their small size and high performance make them ideal for space-constrained applications. Find out more about the everyday items using our compact gearmotors.

Gearmotors are found throughout automotive components, utilised for their compact size, efficiency and performance. These motors help in achieving advanced functionalities in limited spaces. Gearmotors for Car Sear Controls

Rotalink Ltd.

Your Partner in Compact Gearmotor Solutions

Rotalink has a rich history and extensive expertise in the miniature motor industry, providing quality, reliable solutions for various applications all around the world. Established in 1986, Rotalink has 4 decades of experience in delivering compact gearmotors to OEMs on a global scale.

Our range of compact gearmotors includes customisable options designed to meet the specific needs of your application. From standard models to bespoke designs, we offer a wide selection to suit different applications.

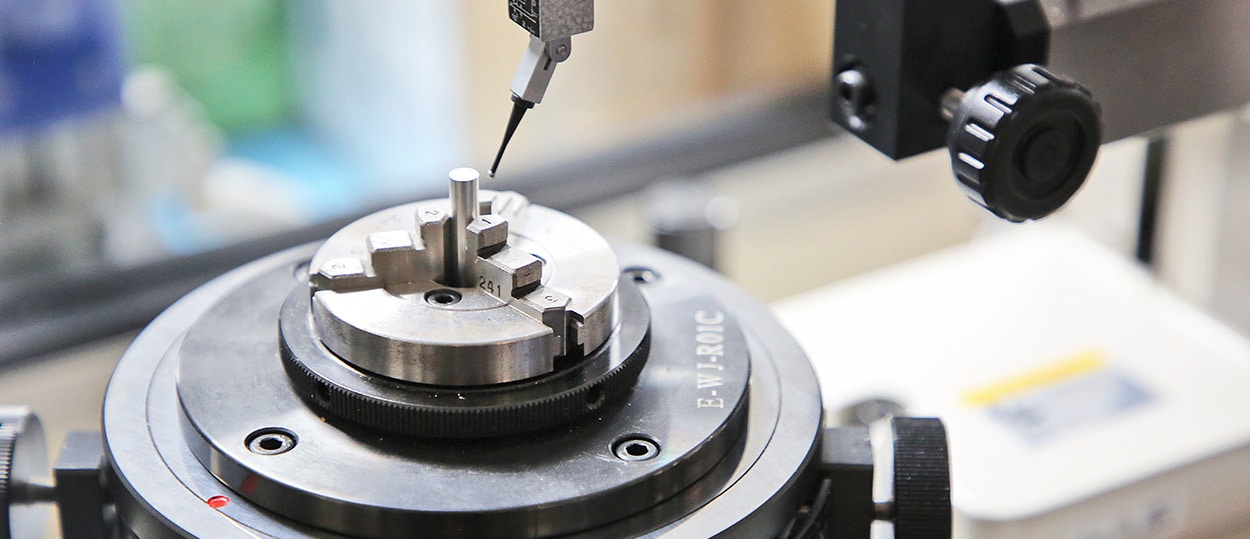

Our team here at Rotalink is committed to quality and continuous innovation, ensuring our products meet the highest standards and industry certifications. Our investment in the latest technology and manufacturing machinery enables our production capabilities. Find out more about our capabilities.