In this article, we're taking a closer look at electric motors. We'll break down the different types, understand what makes each unique, and explore where they find use. From the basics to the latest innovations, join us on this journey to uncover the simple yet fascinating world of electric motors and how they power a variety of industries.

When it comes to electric motors, there are countless variations available to choose from. The majority of miniature electric motors either use alternating current (AC) or direct current (DC). On top of that, motors not only range in different shapes, sizes and power levels, but can also come in brushless, brushed, permanent magnet, or synchronous designs. All of these variations mean there is a fantastic choice of motors to choose from; therefore, allowing you to find the perfect option for the given application whether for domestic, commercial or industrial applications.

Wish to discuss your project with an expert? Contact our team

AC Motors

By using an alternating current, an AC Motor turns electrical energy into mechanical for use in a wide range of different applications. AC motors have a wide range of advantages, including needing minimal power during start-up and offering the ability to control acceleration allowing for continuous and reliable speeds.

AC motors also do not require brushes so giving additional durability compared to brushed DC motors. AC motors are generally found in applications that need steady and consistent levels of power, such as conveyors.

AC Motor Types

AC motors can be split into two main categories - synchronous or induction.

- Synchronous AC motors: The frequency of the electrical current matches the rotation of the rotor. This is ideal for scenarios that require high precision due to the ability to generate consistent speed. Synchronous AC motors are often found within robotic applications.

- AC Induction motors: Induction motors, also known as asynchronous motors, are far more common than synchronous motors. Induction motors are found in a vast range of different appliances within the home as well as within lifting equipment. An induction motor works by using electromagnetic induction from the magnetic field from the stator winding to produce torque.

DC Motors

A DC motor, short for Direct Current motor, is an electrical device that converts direct current electrical energy into mechanical power.

It operates based on the principle of Lorentz force, where the interaction between the magnetic field and the electric current produces rotational motion.

DC Motor Types

- Permanent Magnet DC Motors (PMDC): If you are looking for a miniature electric motor for your project, permanent magnet DC (PMDC) motors offer another fantastic alternative. PMDC motors work differently from other DC motors in the way the magnetic field is generated using fixed magnets within the stators, rather than within the stator windings.

Generally, PMDC motors are smaller than other DC motor varieties. This makes them ideal for use in scenarios that demand the use of miniature electric motors, including within devices such as electric toothbrushes, computer drives and windshield wipers. PMDC motors are also found in various healthcare and leisure industry products, and due to their compact design are extremely cost-effective.

- Brushless DC Motors: DC motors can either come as brushed or brushless. Brushless DC (BLDC) motors require less maintenance than their brushed counterpart, as there is no need to replace worn-out brushes. This makes brushless motors ideal for where maintenance needs to be kept to a minimum.

If you are looking for a more efficient miniature electric motor, then a brushless motor may be the way to go as it does not lose speed into the brushes, which also helps towards a quieter solution. When choosing miniature electric motors, one issue you will find with brushless motors is the fact they require an electronic controller, making the brushless more expensive than brushed ones.

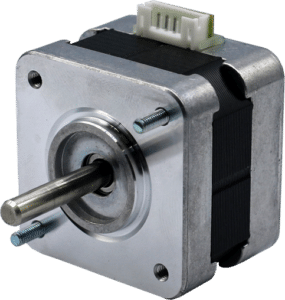

Stepping Motors

A stepping motor, also known as a stepper motor, is a type of electric motor that converts electrical pulses into discrete mechanical movements or steps. Unlike other types of motors that rotate continuously, stepping motors move in precise increments or steps, making them well-suited for applications that require precise position control.

Stepping motors consist of a rotor with teeth or a magnetized structure and a stator with coils or electromagnets. The stator windings are energized sequentially in a controlled manner, generating a magnetic field that interacts with the rotor. By controlling the sequence and timing of the electrical pulses applied to the windings, the rotor moves step by step, either in a clockwise or counterclockwise direction.

Stepping Motor Types

- Permanent Magnet Stepping Motor: This type of stepper motor has a permanent magnet rotor and stator windings. It offers moderate torque and step resolution and is commonly used in applications like printers, scanners, and CNC machines.

- Hybrid Stepping Motor: Hybrid motors combine the features of permanent magnet and variable reluctance motors. They have a toothed rotor with permanent magnets and a stator with both salient poles and windings. Hybrid motors offer high torque, precise step resolution, and excellent holding torque. They are widely used in 3D printers, CNC routers, and automation systems.

| Call our friendly team on +44 (0) 1460 72000 to discuss your next project |